LRA Linear Residential Actuator Installation Guide - 5 - 228158 Revision X13 2-3-2009

Operator Setup

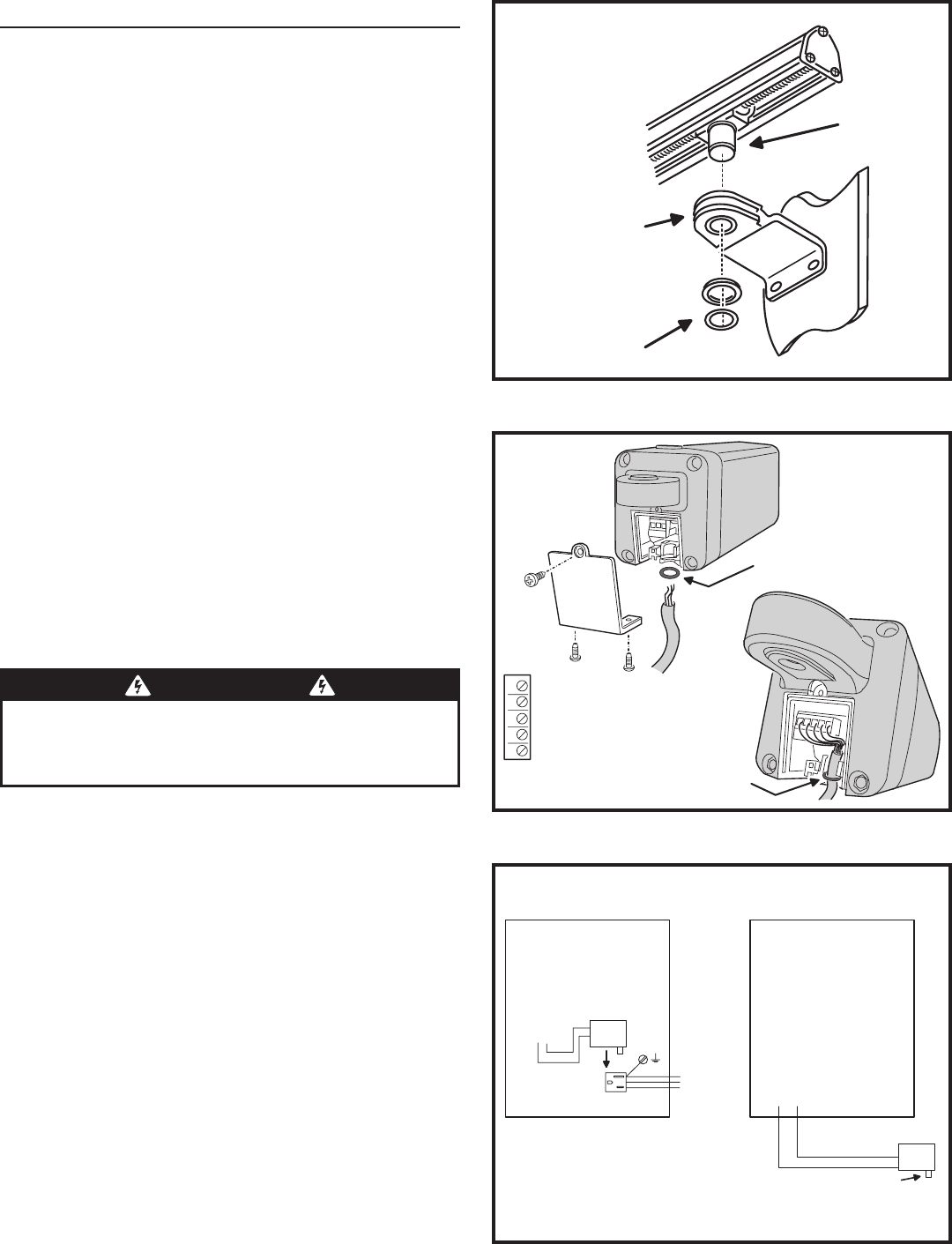

Operator Mounting

The operator mounts on the post bracket pin and into the

gate bracket bushing. Refer to Figure 5.

With the gate closed, carefully position the operator over the mounting 1.

brackets.

Lower the operator onto the post bracket pin while guiding the 2.

operator’s worm drive traveler shaft into the gate bracket bushing.

Install the washer and clip-ring on the post bracket pin.3.

Install the washer and clip-ring on the traveler shaft.4.

Controller Connection

The Controller is mounted in a locked enclosure. Open the

cover for installation access. The operator’s interface cable

plugs into the Controller and connects to the operator’s

5-position terminal block.

Remove the operator’s wiring access plate (see Figure 6).1.

Connect the interface cable to Terminals 1-5 on the Controller (see 2.

wire colors and terminal numbers in Figure 6).

Route the interface cable through a wiring knockout in the control 3.

box and towards the operator. Be sure to leave enough slack in the

interface cable to allow for the gate swing.

Slide the O-ring over the end of the interface cable.4.

Connect the interface cable to the operator’s terminal block matching 5.

the same colors and terminal numbers used in Step 2 (see Figure 6).

Replace the operator’s wiring access plate being careful to align the 6.

O-ring below the cable clamp. The O-ring helps keep out moisture.

AC Power Connection

The control box contains a power disconnect switch to turn

on and off the power available to the operator. Following

wiring specifications on Page 2, incoming power should be

brought into the control box and connected to the labeled

pigtails from the disconnect box. A wiring connections print

can be found on the label inside the cover of the operator.

See Figure 7 for power option examples.

Earth Ground

Install a ground rod and connect it to the control box in every

installation. A good earth ground is necessary to allow the

Controller’s built-in surge and lightning protection circuitry

to work effectively.

✓ NOTE: Do not splice the ground wire. Use a single piece of solid

copper 12 AWG wire between the ground rod and the control box.

Install an 8-foot long copper ground rod within three feet of the control 1.

box.

Use a clamp to connect a solid copper 12 AWG ground wire to the 2.

ground rod.

Route the ground wire to the control box through a wiring knockout.3.

Connect the ground wire to the control box.4.

TRAVELER

SHAFT

GATE BRACKET

BUSHING

WASHER

AND CLIP-RING

Figure 5. Mounting the Operator

Figure 6. Interface Cable Connection

1 2 3 4 5

5 - OPEN LIMIT

4 - COMMON (LIMIT)

3 - CLOSE LIMIT

2 - MOTOR

1 - MOTOR

MATCH TERMINAL NUMBERS

ON OPERATOR & CONTROLLER

PUT O-RING ON CABLE TO

SEAL OUT MOISTURE

O-RING

FITS

IN SLOT

CONTROL BOX

TERMINAL STRIP

CONNECTION

24 VOLTS AC/DC

- +

GROUND

NEUTRAL

HOT

115V POWER

RECEPTACLE

BRING 115V HOT, NEUTRAL, AND

GROUND INTO CONTROL BOX AND

CONNECT TO POWER RECEPTACLE

PLUG TRANSFORMER INTO THE AC

RECEPTACLE, TRANSFORMER OUTPUT

CONNECTS TO THE TERMINAL STRIP

CONTROL BOX

TERMINAL STRIP

CONNECTION

24 VOLTS AC/DC

- +

PLUG-IN

TRANSFORMER

CONNECT TRANSFORMER

TO 115 VAC POWER SOURCE

POWER OPTION #1

(BRING 115V INTO CONTROL BOX)

POWER OPTION #2

(REMOTE LOCATED POWER SUPPLY)

IF BEYOND 500 FT. USE BRIDGE RECTIFIER

TO CONVERT 24 VAC TO 24 VDC AT

PLUG-IN TRANSFORMER LOCATION

MAXIMUM DISTANCE

500 FT. 12 GA. WIRE

Figure 7. Power and Ground Connections

WARNING

ALL AC ELECTRICAL CONNECTIONS TO THE POWER SOURCE AND

THE OPERATOR MUST BE MADE BY A LICENSED ELECTRICIAN

AND MUST OBSERVE ALL NATIONAL AND LOCAL ELECTRICAL

CODES.