Selection Table

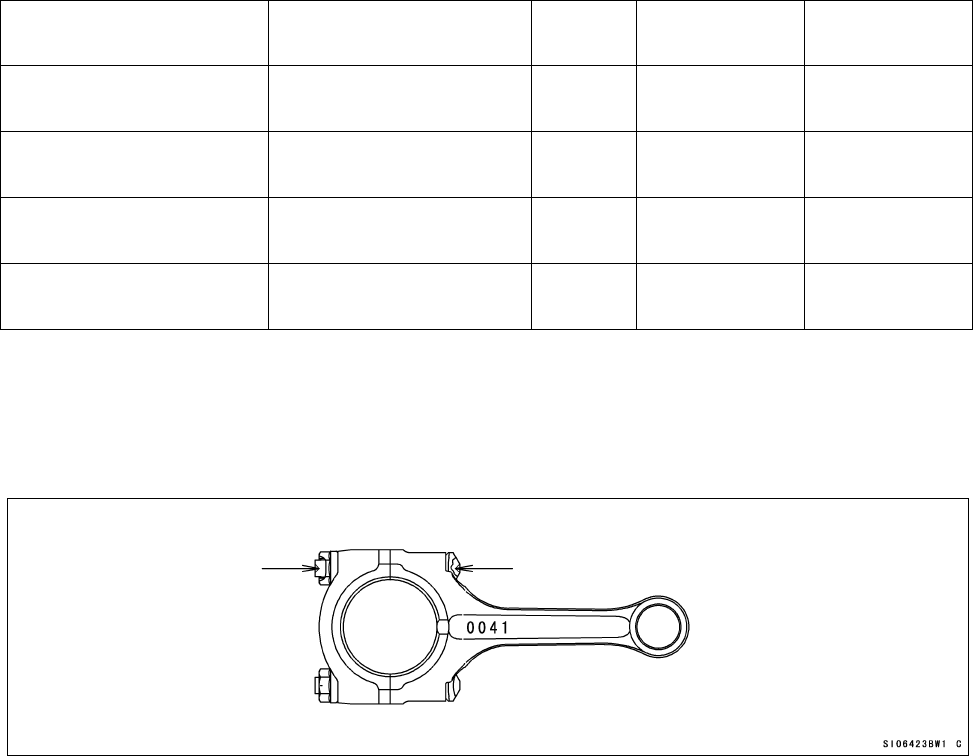

Connecting Rod Big End

Inside Diameter

Crankpin Diameter Mark

Size

Color

Part Number

(STD)

Part Number

(KIT)

None

○

(33.000 mm ~ 33.008 mm) (29.992 mm ~ 30.000 mm)

brown 92139-0167 92139-0196

None None

(33.000 mm ~ 33.008 mm) (29.984 mm ~ 29.992 mm)

black 92139-0166 92139-0195

○ ○

(33.008 mm ~ 33.016 mm) (29.992 mm ~ 30.000 mm)

black 92139-0166 92139-0195

○

None

(33.008 mm ~ 33.016 mm) (29.984 mm ~ 29.992 mm)

blue 92139-0165 92139-0194

Connecting Rod Bolts

Use the original connecting bolts and nuts.

The original connecting rod bolt has recesses at both ends to measure its length and

determine the bolt stretch.

Install the original bolts into the connecting rod.

Before every tightening, use a point micrometer to measure the length of the bolts and

record the values to find the bolt stretch.

Apply a small amount of molybdenum disulfide grease to the threads of bolts.

Tighten the big end nuts at the torque of 11.8 ±2 N·m (1.2 ±0.2 kgf·m): reference

Check the length of the bolts and find the bolt stretch.

Bolt Length after tightening – Bolt Length before tightening = Stretch

Bolt Stretch

Usable Range: 0.33 ~ 0.38 mm (0.013 ~ 0.015 in.)

Turn the big end nuts more until the bolt stretch reaches the usable range.

NOTE

Replace the original bolts with new ones if they have already been tightened up to usable

range 2 times.

19