If you don’t adjust the valve timing for racing, install the camshaft sprocket to the kit

camshaft using the round bolt holes and adjust the cam chain timing according to the

Ninja ZX-6R Service Manual. If you adjust the valve timing, install the sprocket to the

camshaft between the adjustable range of the long bolt holes.

Tighten the camshaft sprocket bolts to 15 N·m (1.5 kgf·m, 11.0 ft·lb) of torque.

Valve Timing (when the round bolt holes are used)

Timing (cam lift center) Intake Exhaust

Original 105° 110°

Race use 105° 110°

When grinding the cylinder head bottom surface, grinding the cylinder top surface or

using thinner gaskets, be sure the valve to piston clearance especially.

When using the sprocket long bolt holes and adjusting the valve timing to be different

from the standard timing, check the valve to piston clearance of all cylinders after

adjusting the valve clearance correctly.

Valve to Piston Clearance (Min.)

Intake 0.8 mm

Exhaust 1.4 mm

If the valve to piston clearance is less than the minimum value, do not start the engine

because the valves will touch the piston and the engine may be damaged.

Measure the valve to piston clearance at about 12° ATDC (Intake) and 11° BTDC

(Exhaust) of crankshaft timing. At this point, the valve to piston clearance will be

minimum.

Valve Springs

The original machine’s valve springs should be used

.

Cylinder Compression

To adjust the cylinder compression, adjust the thickness of the cylinder head gasket and

the cylinder base gasket or smooth the cylinder top surface to make the piston squish

0.65 ~ 0.8 mm. Keep the piston squish more than 0.65 mm.

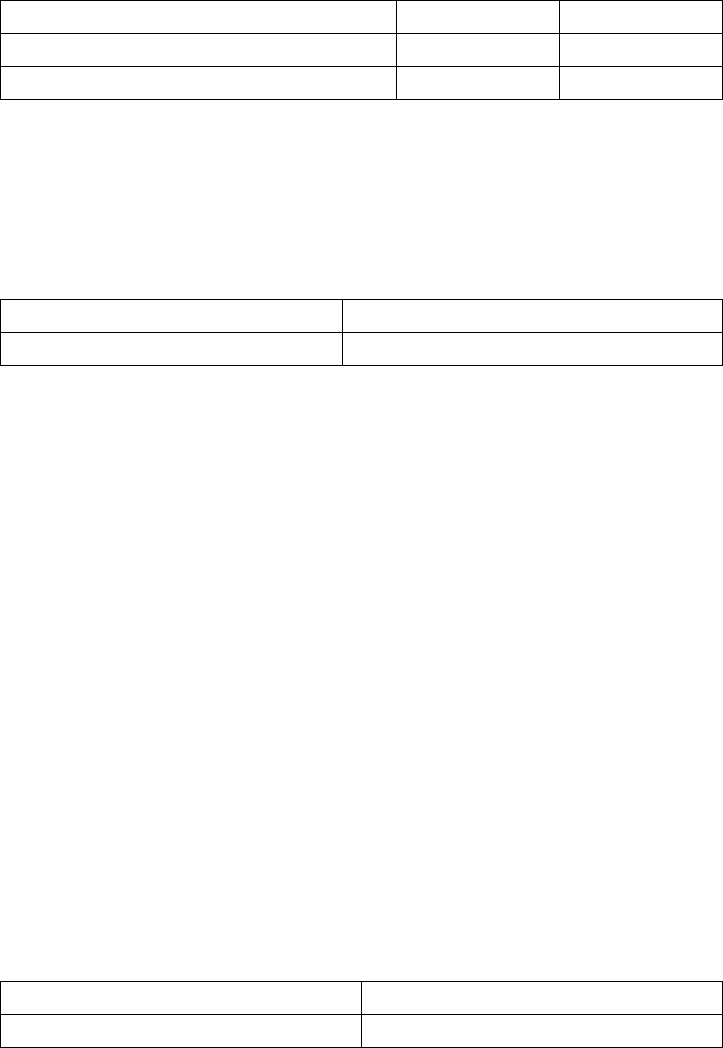

Position the piston at Top Dead Center, and put a small piece of modeling clay on the

shoulder of the piston. Install the cylinder head gasket and cylinder head, and tighten

the head bolts to the specified torque.

Remove the cylinder head and measure the thickness of the clay. The thickness of the

collapsed clay is the size of the squish.

Squish Measurement

[1] Front and Rear 0.65 ~ 0.80 mm

[2] Left and Right 0.67 ~ 0.85 mm

The most preferable squish measurement is [1] 0.65 mm/[2] 0.67 mm.

Select proper cylinder head gasket and cylinder base gasket.

Note that by grinding the cylinder head surface only left and right squishes become

narrower, while by grinding the cylinder top surface or decreasing the gasket-thickness

all the squishes become narrower.

14