DISASSEMBLY, REASSEMBLY, INSPECTION, AND MAINTENANCE 3-61

Camshaft

Disassembly

•

Remove the crankcase cover.

•

If axial play adjustment shims are provided for the crankshaft and the

camshaft, remove the shims and identify them so that they can be

installed correctly during reassembly.

•

Place the cylinder block on a base so that the flywheel side faces

down. Keep the tappet (or the HLA on FE350 or 400) pushed up

towards the cylinder head.

•

After aligning the matching marks on the crankshaft gear and the

camshaft gear, take out the camshaft.

NOTE

Clean the mating surfaces of the crankcase and the crankcase

cover of any gasket residues.

•

Take out the tappet or the HLA from the crankcase.

NOTE

After removing the tappet, place marks on them to identify the

intake and exhaust tappets so that they can be reinstalled in their

original positions.

Keep the end of the HLA in which the snap ring is visible upright.

If it is placed on its side, the oil that is sealed in the unit could leak

out, disabling the HLA function.

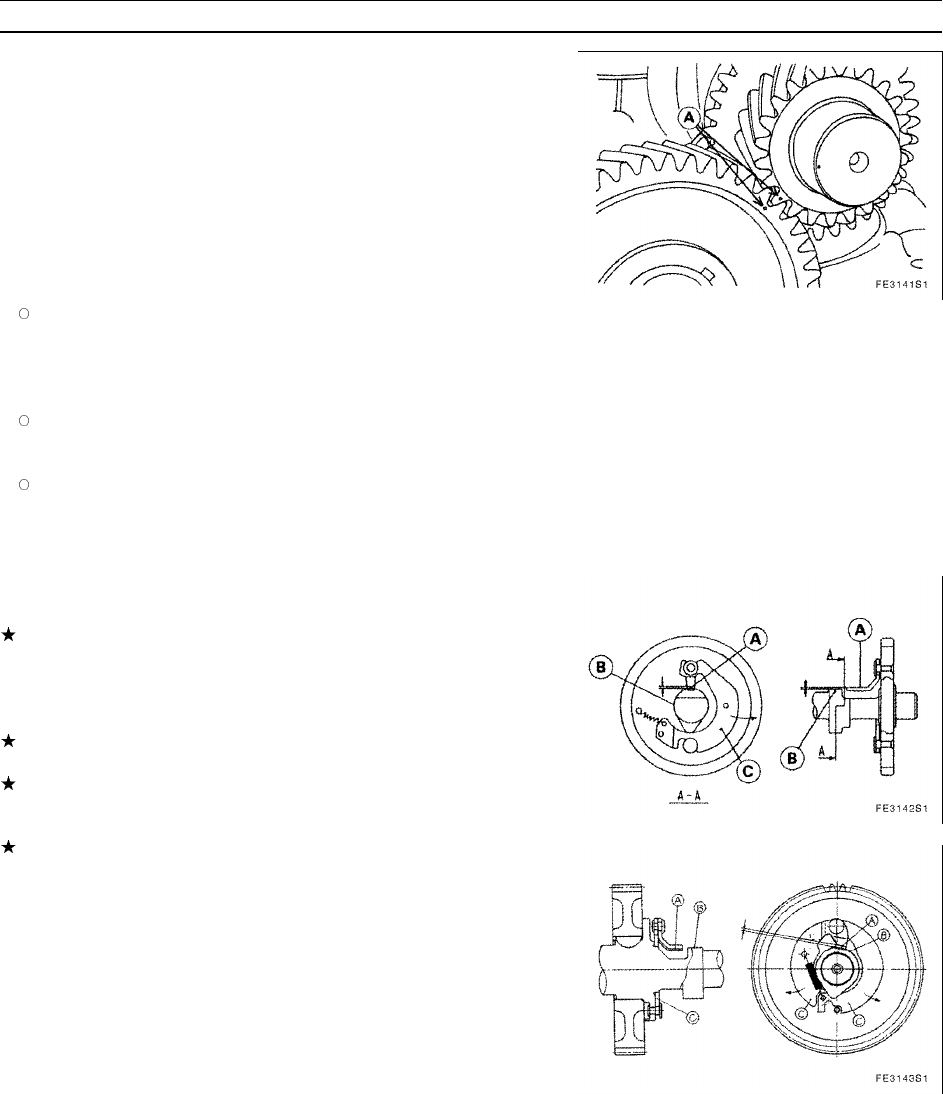

A: Matching Marks

Inspection

•

Inspect the camshaft and cam gear for any broken teeth or wear.

If they are abnormally worn or have broken teeth, replace the

camshaft with a new one.

•

Inspect the camshaft to make sure that its automatic compression

Reduction (ACR) function operates smoothly and does not have any

damage or abnormal wear.

When the weight [C] is closed, if the top of the arm [A] is lower than

the base [B], replace the ACR with a new one.

When the weight [C] is pulled entirely outward with your finger, if the

top of the arm [A] is higher than the cam base [B], replace the ACR

with a new one.

If ACR parts are worn, replace the ACR with a new one.