3-44 DISASSEMBLY, REASSEMBLY, INSPECTION, AND MAINTENANCE

Cylinder Block and Crankcase Cover

•

Verify that a crankshaft or the camshaft that requires an axial play

adjustment shim is provided with an adjustment shim. (Refer to the

section on Axial Play Adjustment.)

•

Verify that the governor weight is closed. Also verify that the governor

arm is positioned so that its front receives the end of the governor

sleeve. (Refer to the section on Governor Mechanism.)

•

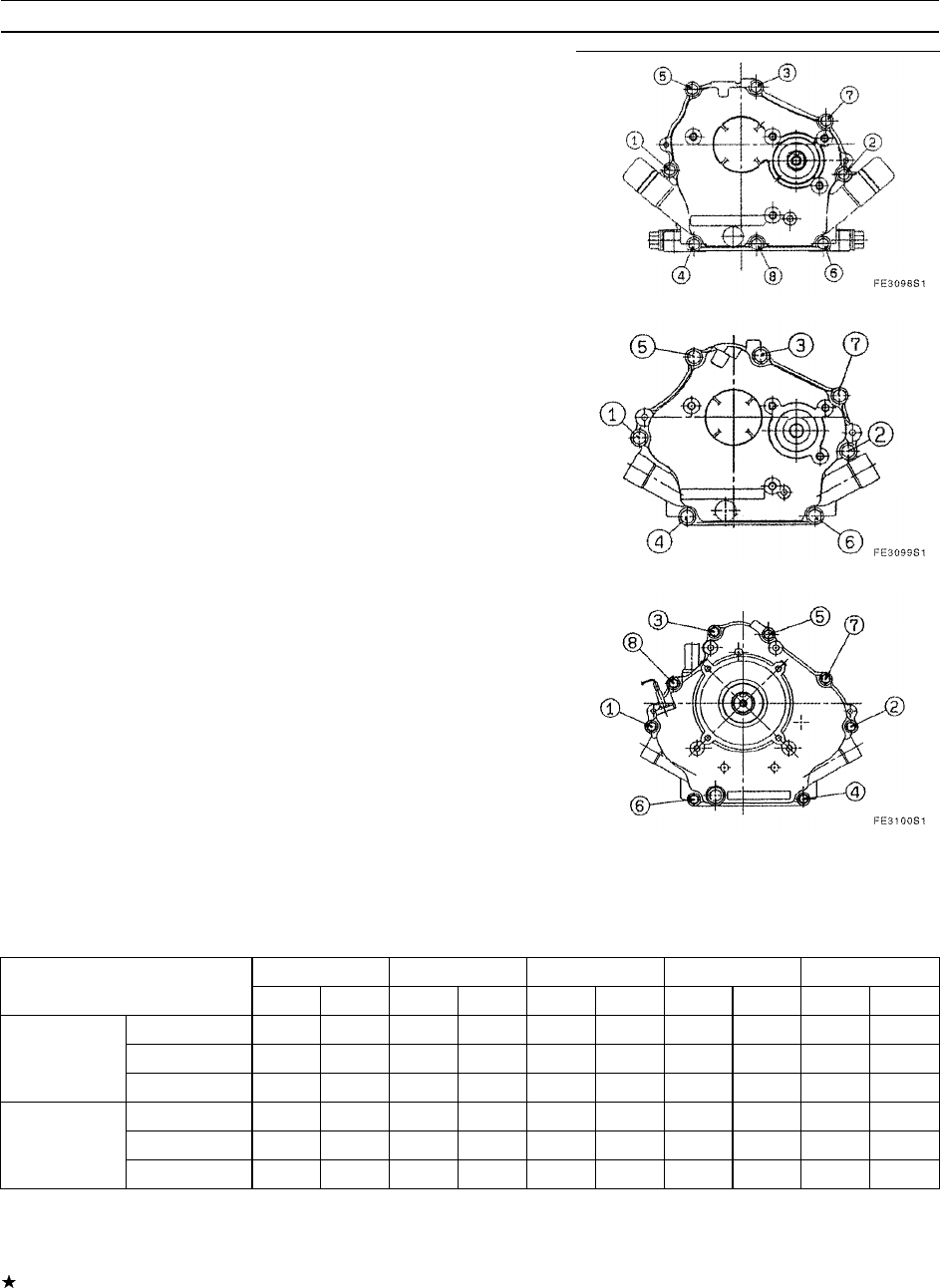

Install the crankcase cover while paying attention to the meshing of

the governor gear, evenly tighten the retaining bolts in the sequence

given in the diagram, and tighten them to the specified torque. (Refer

to the section on Tightening Torque Specifications.)

Ball Bearing

•

The table below lists the areas in which ball bearings are used. An

empty area signifies that the case acts directly as a plain bearing.

Ball Bearing Areas and Nominal Numbers

FE120 FE170 FE250 FE290 FE350, 400

Type D Type G Type D Type G Type D Type G Type D Type G Type D Type G

Crankshaft 6204 6204 6305 6305 6206 6206

Flywheel Side Camshaft

Balancer Shaft - - - - - - - -

Crankshaft 6204 6204 6205 6205 6206 6206 6306 6306 6207 6207

PTO Side Camshaft 6204 6205 6206 6306 6207

Balancer Shaft - - 6202 6202 - - - - - -

Note: The numbers indicate the nominal numbers of the ball bearings.

•

To inspect a ball bearing, first clean the bearing in solvent and allow

it to dry. Then, apply engine oil and gently spin it with your hand.

If the bearing is noisy, does not spin smoothly, or has excessive play,

replace the bearing.