DISASSEMBLY, REASSEMBLY, INSPECTION, AND MAINTENANCE 3-35

Valve System

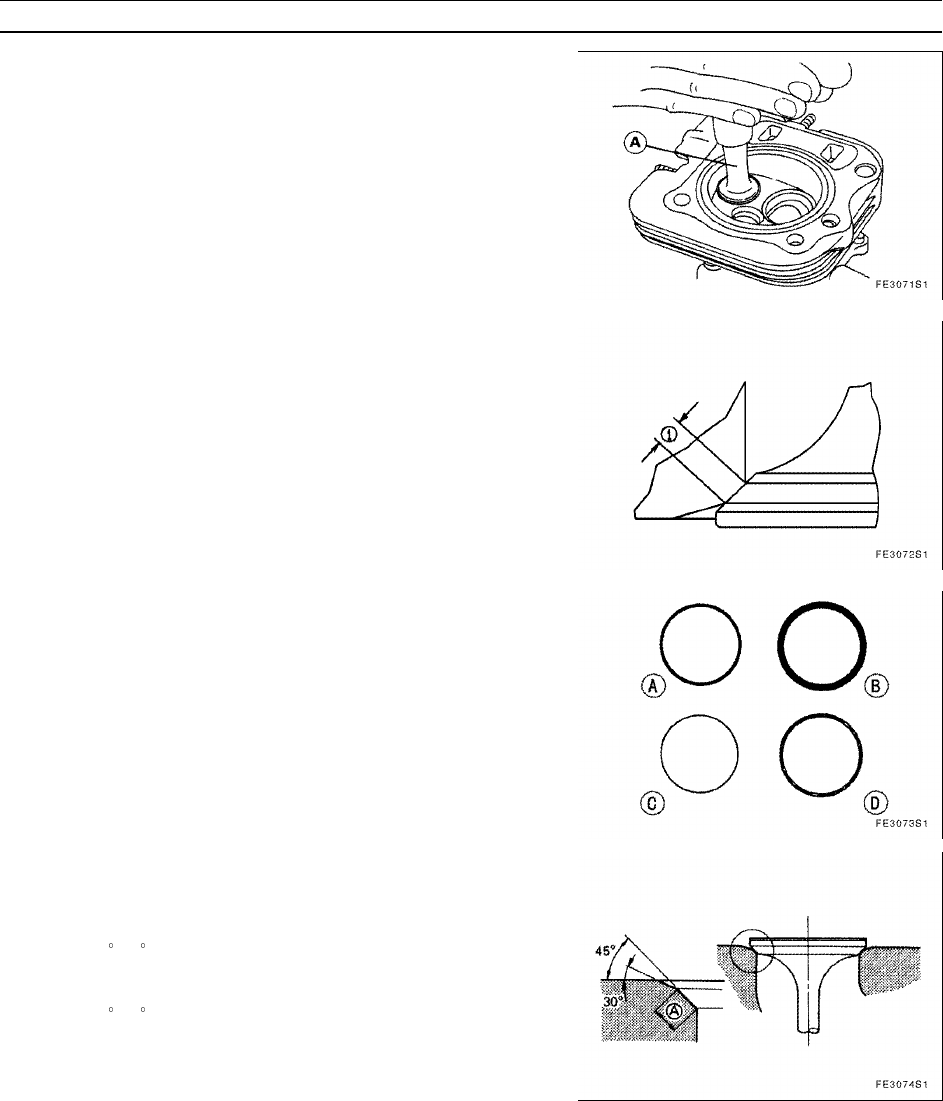

Valve Seat Inspection and Lapping

A prerequisite for inspecting the valve seat contact is that the valve

guide and the valve stem are normal.

•

Apply a thin layer of fine lapping compound on the contact surface of

the valve.

•

Using a lapper [A], lap the valve against the seat by rotating the valve.

•

Pull out the valve and inspect whether there is an even contact at the

valve seat along its entire circumference. If not, lap the valve and the

valve seat.

•

Lap 8 to 10 times and inspect the contact each time. Repeat this

process until there is contact along the entire circumference.

•

After completing the lapping, completely wash off the compound from

all parts and allow the cylinder head to dry.

A: Lapper

1. Valve Seat Contact Width

Valve Seat Correction

If the contact width of the valve seat is nearing the service limit, or

there are small depressions or wear on the valve seat, correct the valve

seat.

•

Using a 45 (30 only for the intake on FE350 and 400) valve seat

cutter, apply a light force to smoothly cut the valve seat to create a

concentric circle.

•

Using a 30 (15 only for the intake on FE350 and 400) valve seat

cutter, make a shallow cut so that the valve seat contact [A] will have

the standard width.