DISASSEMBLY, REASSEMBLY, INSPECTION, AND MAINTENANCE 3-29

Valve System

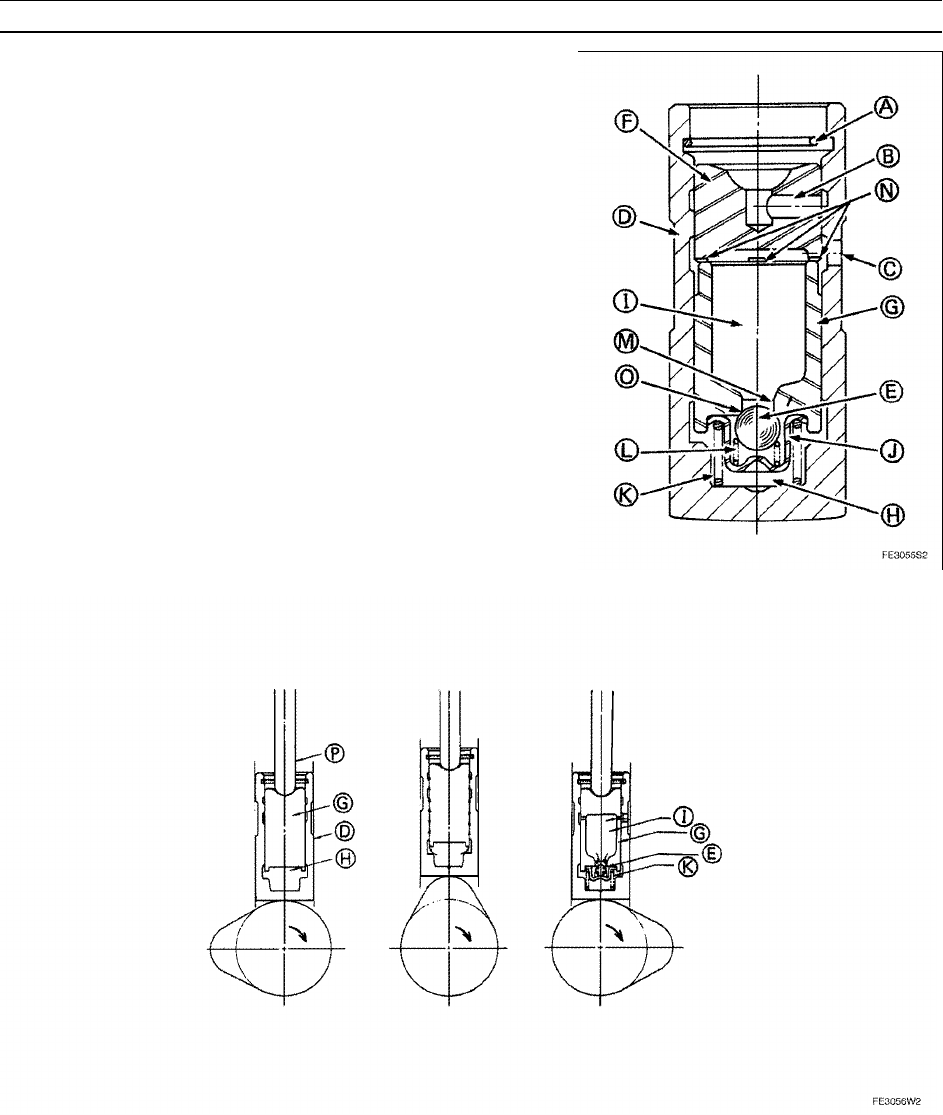

HLA Construction and Operation

•

When the cam pushes the HLA upward, the oil in the high-pressure

chamber [H] tries to flow back to the oil pool [I] of the plunger [G]

by passing through the passage [M], but because the check ball [E]

closes the passage [M], the oil cannot flow back and it causes the

hydraulic pressure in the high-pressure chamber [H] to rise.

•

The oil of the high-pressure chamber [H] in which the hydraulic

pressure has risen leaks little by little through the gap (leak-down

rand) between the plunger [G] and the HLA body [D]. As a result, the

HLA shrinks slightly and pushes the pushrod [P] upward.

•

When the rotation of the cam causes the HLA to descend to the cam

base circle, the pressurized oil from the oil pump passes through the

oil hole [C] in the HLA body [D], travels through the oil groove [N] that

is cut into the socket [F], and enters the oil pool [I] in the plunger [G].

•

After filling the oil pool [I], the oil pushes open the check ball [E], and

flows into the lifter cage [J] and the high-pressure chamber [H], in

order to correct the valve train to achieve zero clearance.

A: Snap Ring

B: Oil Metering Hole

K: Plunger

L: Check Valve Spring

O: Check Valve Seat

P: Pushrod