28 PREPA

RATION

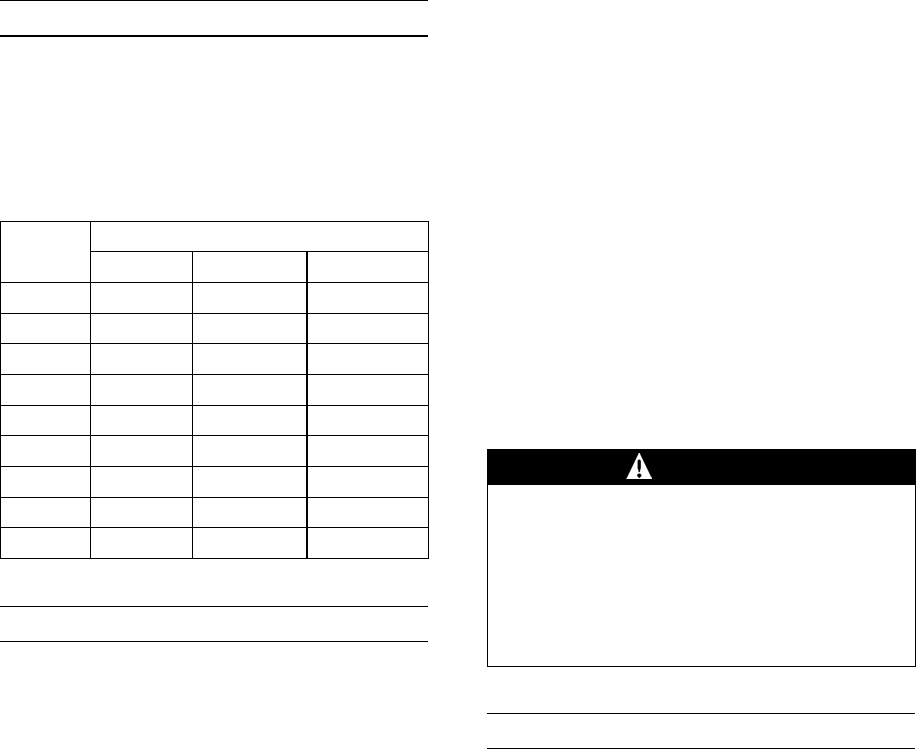

Standard Torque Table

This table relating tightening torque to thread

diameter, lists the basic torque for bolts and

nuts. Use this table for only the bolts and nuts

which do not require a specific torque value.

All of the values are for use with dry solvent

-cleaned threads.

General Fasteners:

Threads Torque

dia. mm N·m kgf·m ft·lb

5 3.4 a 4.9 0.35 a 0.50 30 a 43 in·lb

6 5.9 a 7.

8

0.60 a 0

.80

52 a 69 i

n·lb

8 14 a 19 1.4 a 1.9 10.0 a 13.5

10 25 a 34 2.6 a 3.5 19.0 a 25

12 44 a 61 4.5 a 6.

2

33 a 45

14 73 a 98 7.4 a 10.0 54 a 72

16 115 a 155 11.5 a 16.0 83 a 115

18 165 a 225 17.0 a 23

.0

125 a 165

20 225 a 325 23 a 33 165 a 240

Test Ride the Motorcycle

•

Complete the test ride checklist.

Control Cables:

Throttle cables must work

without binding in any

steering position.

Steering: Action is free from

lock-to-lock.

Suspension: Check operation front

and rear.

Engine: Electric starter works

properly and engine

starts promptly. Good

throttle response and

return.

Transmission

and Clutch:

Smooth operation.

Brakes: Adequate, smooth

stopping power, No

drag.

Speedometer

and Tachometer:

Check operation.

Electr

ical System:

Headlight - check high and low beams.

Taillight - check operation.

Brake Li

ght - check operation.

Turn Signal Lights - check operation.

Horn - check operation.

Instrument Lights and Indicator Lights –

check operation.

Engine Stop Switch Works:

Starter Interlock Switch Works:

No Unusual Noises:

No Fuel, Oil, Brake Fluid, or Coolant

Leaks:

PREPARATION COMPLETE.

WARNING

New tires are slippery and may cause

loss of control and injury. A break-in pe-

riod of 160 km (100 miles) is necessary

to establish normal tire traction. During

break-in, avoid sudden and maximum

braking and acceleration, and hard cor-

nering.

A&P Check List

•

CompletetheA&PCheckList.