18 PREPA

RATION

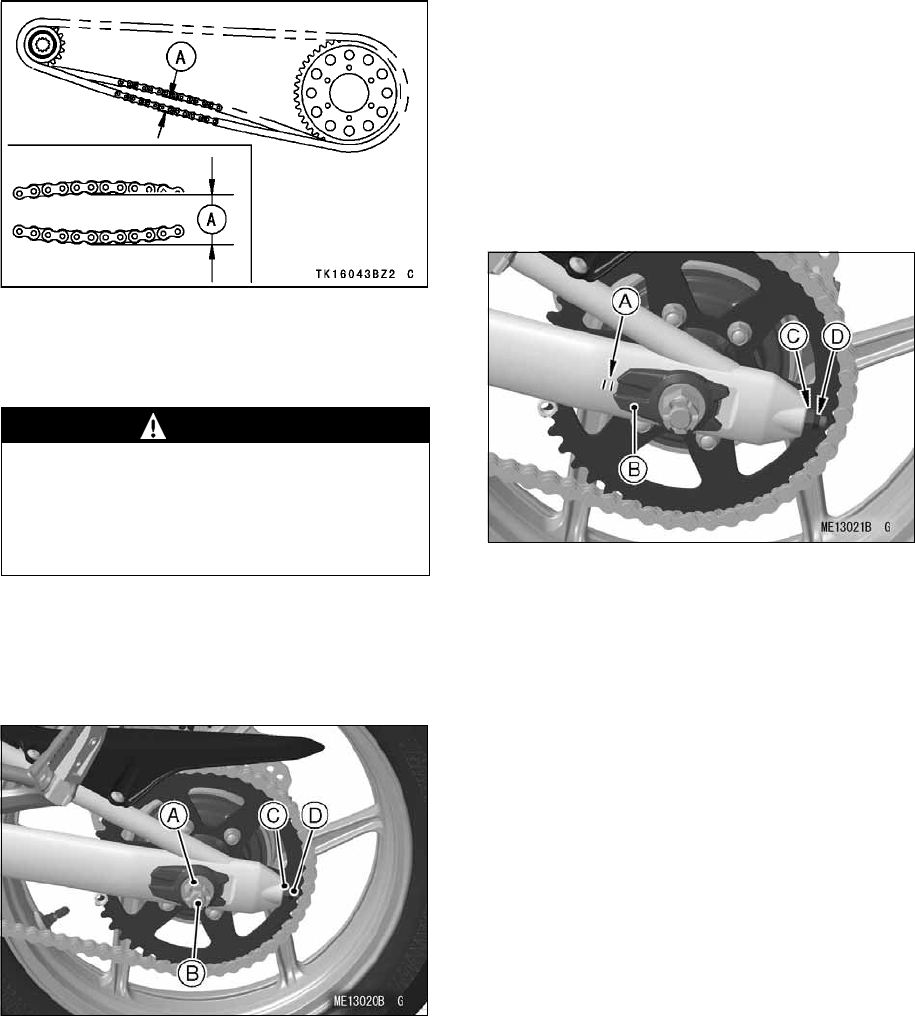

A. 25

a

35 mm (1.0

a

1.4 in.)

•

If the drive chain is too tight or too loose, ad-

just it so that the chain slack will be within the

standard value.

WARNING

A chain that breaks or jumps off the

sprockets could snag on the engine

sprocket or lock the rear wheel, se-

verely damaging the motorcycle and

causing it to go out of control.

Drive Chain Slack Adjustment

•

Loosen the left and right chain adjuster lock-

nuts.

•

Remove the cotter pin, and loosen the rear

axle nut.

A. Rear Axle Nut

B. Cotter Pin

C. Drive Chain Adjusting Nut

D. Drive Chain Adjuster Locknut

•

If the chain is too loose, turn in the left and

right chain adjusting nuts evenly.

•

If the chain is too tight, turn out the left and

right chain adjusting nuts evenly.

•

Turn both chain adjusting nuts evenly until the

drive chain has the correct amount of slack.

To keep the chain and wheel properly aligned,

the left wheel alignment indicator should align

with the same swingarm mark that the right

indicator aligns with.

A. Chain Adjuster Alignment Marks

B. Indicator

C. Drive Chain Adjusting Nut

D. Drive Chain Adjuster Locknut

NOTE

żWheel alignment can also be checked using

the straightedge or string method.

•

Tighten both chain adjuster locknuts.

•

Tighten the rear axle nut to the specified

torque.

Torque: 108 N·m (11.0 kgf·m, 80 ft·lb)

•

Rotate the wheel, measure the chain slack

again at the tightest position, and readjust if

necessary.

•

Install a new cotter pin.

NOTE

żWhen inserting the cotter pin, if the slots in the

nut do not align with the cotter pin hole in the

axle, tighten the nut clockwise up to the next

alignment.

żIt should be within 30 degrees.

żLoosen once and tighten again when the slot

goes past the nearest hole.