GEK-95352

7

The SYSTEM REED CRITICAL

FREQUENCY should be 25% above or

below motor operating speed in order to

avoid excessive vibration.

C. Alignment of Solid-Shaft Motors

Accurate mechanical lineup is essential

for successful operation. Mechanical vi-

bration and roughness when the motor is

running may indicate poor alignment. In

general, lineup by straight edge across,

and feeler gages between coupling halves

is not sufficiently accurate. It is recom-

mended that the lineup be checked with

dial indicators. The space between cou-

pling hubs should be maintained as rec-

ommended by the coupling manufacturer.

D. Couplings for Hollow-Shaft

Motors

1. General

Vertical hollow-shaft motors are

designed for driving deep-well, tur-

bine-type pumps and can be

equipped with either self-release,

bolted, or non-reverse couplings as

described in following sections.

These couplings are located at the

top of the motor and allow pump

impeller position to be adjusted eas-

ily. The type of coupling is specified

by the customer. Remove the top

cap for access to the coupling.

Two slots are provided in the out-

side rim of the coupling so that a bar

can be inserted to keep the assembly

from turning while the adjustment

of pump impeller clearance is being

made. A coupling bolt can be

screwed into one of the extra tapped

holes in the top endshield to provide

a stop for the bar.

To prevent breakage, coupling bolts

must be tightened to torque values

indicated below for bolted or non-

reverse couplings

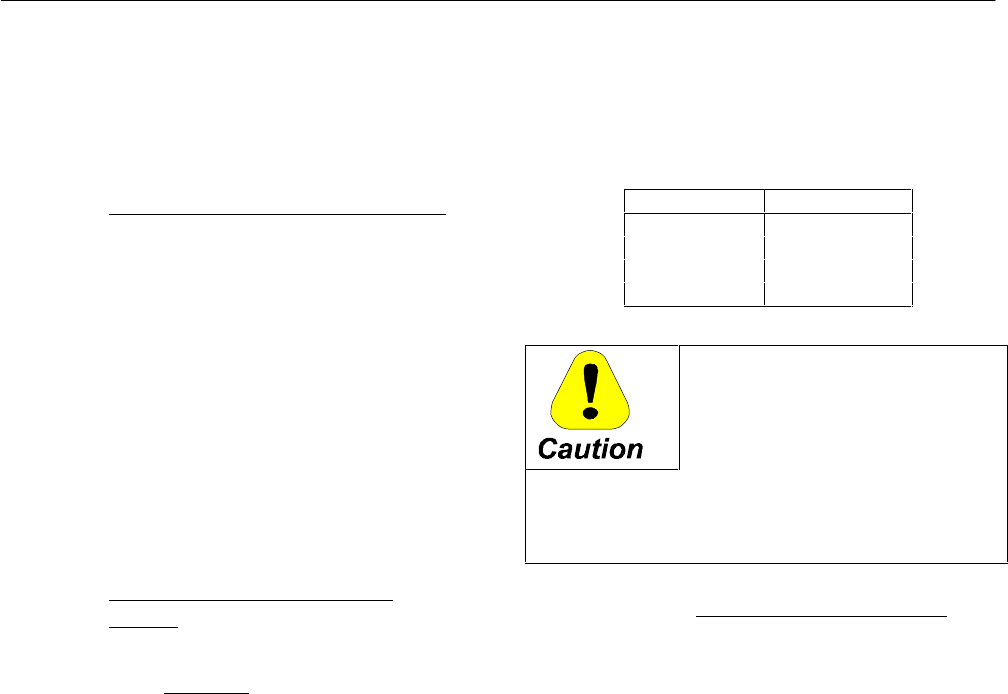

Bolt Size Torque

1/2 90 lb-ft

5/8 180 lb-ft

3/4 320 lb-ft

1 710 lb-ft

It shall be the installer’s re-

sponsibility in all cases to as-

certain that these torque values

are used and maintained. This

shall include those instances

when the coupling comes mounted in the mo-

tor. Failure to comply may cause the coupling

bolts to break, with resultant extensive damage

to the equipment.

2. Self-Release Couplings

Should the motor accidentally be

run in the reverse direction, the

pump line-shaft joints may unscrew.

The self-release coupling acts to

limit the amount of this unscrewing.

In normal operation, torque from the

motor is transmitted by the lower

half-coupling through the driving

pins to the upper half-coupling, and

then to the pump shaft. If reversal

occurs and the pump shaft starts to

unscrew and lengthen, the upper

half of the self-release coupling is

lifted up off of the driving pins, thus

uncoupling the pump from the mo-

tor. See Figure 1, where a self-

release coupling is shown to the left

of the shaft center-line.

NOTE : THAT SELF-RELEASE COU-

PLINGS CANNOT CARRY UP-

THRUST

Proper functioning of a self-release

coupling depends upon several fac-

tors. The pump shaft adjusting nut

must be securely attached to the top