GEK-95352

22

Windings cleaned with solvent

should be dried thoroughly by cir-

culation of dry air before voltage is

applied.

*One commercial source of 1,1,1

Trichloroethane is Chlorothene NU,

which is a Trade-mark of the Dow

Chemical Company, Midland,

Michigan.

5. Revarnishing Windings

After several cleanings with water

and detergent it may be necessary to

revarnish the winding. GE 9522 or

equivalent varnish treatment is rec-

ommended for Class B and Class F

systems. This varnish is available

from the General Electric Company

insulating Materials Department or

GE Service Shops.

All systems treated with varnish No.

9522 or equivalent must be baked

until the windings are at 150°C for

four hours.

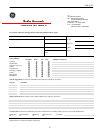

VI. RENEWAL PARTS

When ordering parts, give description and

state quantity of parts desired, together

with the nameplate rating, model, and se-

rial number of the motor. For couplings,

also specify the type, bore, and keyway

size.

Requests for additional copies of these

instructions or inquiries for specific in-

formation should be addressed to the

nearest sales office of the General Electric

Company.