GEK-95352

20

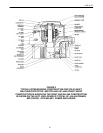

2. Place coil (without inlet / out-

let pipes C) in endshield and secure

loosely.

3. Stick inlet-outlet pipes C

through holes in end shield wall and

check line up of pipes and end

shield holes by screwing pipes

loosely into cooling coil elbow.

Pipes should be centered in holes in

end shield wall. Adjust cooling coil

as needed but Do Not Tighten

Parts Yet.

4. Thread part A over pipes and

screw A into end shield loosely.

Adjust position of cooling coil as

necessary to let pipes exit without

strain and then secure cooling coil

into end shield.

5. Remove parts A and C and put

pipe joint compound on threads. In-

spect outer end and slots in C pipes

and remove any burrs or sharp

edges to prevent damage to O-Ring

during assembly. Then screw pipes

C hand-tight into cooling coil el-

bows, being careful not to bend or

damage the cooling coil when tight-

ening C. Next, tighten C by using

wrench on hex fitting at inner end of

C.

6. Next, slide part A into place

and screw tightly into end shield,

being careful not to damage outer

surface of C where O-Ring will seat.

7. Check gap between endshield

wall and inner surface of A. If this

exceeds 1/4", endshield hole should

be tapped deeper.

8. Check position of end of C

with respect to outer face of A. See

Figure 4 for limiting dimensions.

9. Install 3 set-screws E in A

120° apart and tighten securely to

lock A into position and keep it

from unscrewing. Set-screws should

bite into surface of endshield.

10. Be very careful not to damage

or mar outer surface of C where O-

Ring seats.

11. Re-check outer end and slot of

C and remove any burrs or sharp

edges to prevent damage to O-Ring

during assembly. Then lubricate O-

Ring and slide it into position

shown in Figure 4. Be sure to push

it in until it seats against A.

12. Slide part B into place and se-

cure with 3 socket-head screws F.

Tighten F screws until flange of B

seats solidly against A. There

should never be a gap between A

and B. Use ”Loc-Tite” on threads of

F-screws to prevent their unscrew-

ing.

Parts A and B compress the O-Ring

against C and seal oil into motor and wa-

ter into coil.

13. Pressure check entire system.

H. Insulation and Winding

Maintenance

1. General

For long life and satisfactory opera-

tion, insulated winding should be

kept clean and free of dirt, oil, metal

particles, and other contaminants. A

variety of satisfactory and accept-

able methods are available for

keeping equipment clean. The

choice of method will depend

greatly on time, availability of