GEK-95352

17

TABLE II

OIL VISCOSITY

(For a particular motor, refer to the lubrication nameplate or instructions.)

Bearing Function Oil Viscosity - SUS

and Location Bearing Type

@100°F@°210 F

GE Spec

Thrust Bearing Angular Contact Ball 150 45 D6B6A

(In top endshield) Spherical Roller 600 70 D6B14C1

or 300 53 D6B6B

Guide Bearing Ball 150 45 D6B6A

(In base endshield)

Oil-lubricated bearing housings are pro-

vided with large settling chambers in

which dust, dirt, and sludge collect. Un-

less the oil has been permitted to oxidize,

the draining of the old oil during regular

changes will usually provide sufficient

flushing action to clean out the reservoir.

Whenever the motor is disassembled for

general cleaning and reconditioning, the

bearing housing may be washed out with

a suitable cleaning solvent. 1,1,1 Trichlo-

roethane may be used, following the same

instructions and cautions as shown for

cleaning windings. Avoid using any sol-

vent that will soften the paint used on the

interior of’ the oil reservoir. Be sure that

the oil metering hole is clear, and then dry

the housing thoroughly before reassem-

bly.

E. End-Play Adjustment

1. General

Most high-thrust motors are de-

signed to withstand only momentary

up-thrust. This up-thrust, which can

exist for a few seconds during

starting, is taken by the lower guide

bearing. To prevent the thrust bear-

ing from losing radial stability dur-

ing this time, the motor end-play is

limited to a small amount by ad-

justment of the motor shaft nut. This

adjustment is made at the factory

and need not be disturbed on a new

motor. However, should the motor

be disassembled for any reason, the

adjustment must be made during re-

assembly to avoid damaging the

bearings, or having some rotating

part rub against a stationary part.

The procedure depends upon the

type of thrust bearing.

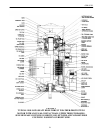

2. End-Play Adjustment – Ball

Thrust Bearing

For a motor with angular-contact

ball thrust bearings, refer to Figure

1. When the motor shaft nut is tight-

ened, the rotor, shaft, and lower

bearing are drawn up until the outer

ring of the lower bearing seats

against the lower bearing cover.

Further tightening of the nut pre-

loads the bearings. (Note that shoul-

der on the shaft below the lower

half-coupling is purposely located

so that it does not seat against the

coupling.)

The best way to adjust the nut is by

trial, using an indicator between the

lower half-coupling and top end-

shield, and lifting the rotor to check

the end-play after each setting of the

nut until between 0.002 and 0.005”