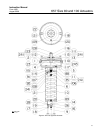

657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

9

(used with group 1 springs only), and spring seat

(keys 115, 114, 35, and 11).

11. Remove seal bushing (key 111) and diaphragm

casing cover O-rings (keys 112 and 113) from upper

diaphragm casing (key 123). Replace with new parts

if necessary. Apply lithium grease lubricant to the

O-rings.

12. Remove actuator spring (key 6).

Size 100 Assembly

Note

Units using a group 2 spring require

one spring seat (key 11) on each end

of the spring (key 6); units using a

group 1 spring require only one spring

seat on the diaphragm end of the

spring as shown in figure 5.

1. Place the spring and spring seats (keys 6 and 11)

inside the spring case.

2. For actuators using a group 1 spring, pack the

thrust bearing (key 35) with lithium grease lubricant

(key 241). Place bearing on the spring seat.

3. Screw the hex jam nut and adjusting nut (keys

115 and 114) onto the actuator stem.

4. Install the lower diaphragm casing (key 5) on the

actuator tie rods (key 21). Secure with hex nuts.

Note

Before installing diaphragm plate (key

4), rotate adjusting nut (key 114) until

the top of the actuator stem is 264 mm

(10-3/8 inches) above the inside

surface of the lower casing (key 5).

When installing diaphragm (key 2), be

certain that the rubber side of the

diaphragm faces away from the spring.

CAUTION

To avoid product damage, smooth the

edge of the diaphragm to avoid

wrinkling, and be careful that the

diaphragm fold does not get pinched

when the upper casing (key 1) is

installed.

5. Install washer, diaphragm plate, diaphragm,

diaphragm retainer, and backup plate

(keys 117, 4, 2, 110 and 13).

6. Apply lithium grease lubricant (key 241) to the

thread on the diaphragm end of the actuator stem

(key 10).

7. Position the upper diaphragm casing (key 1) on

the diaphragm (key 2), and align the holes.

Note

If backup plate (key 13) interferes with

installation of upper casing, rotate

adjusting nut (key 114) to move the

plate.

Note

When you replace actuator

diaphragms in the field, take care to

ensure the diaphragm casing bolts are

tightened to the proper load to prevent

leakage, but not crush the material.

Perform the following tightening

sequence with a manual torque

wrench for size 80 and 100 actuators.

CAUTION

Over-tightening the diaphragm casing

cap screws and nuts can damage the

diaphragm. Do not exceed 68 NSm (50

lbfSft) torque.

Note

Do not use lubricant on these bolts

and nuts. Fasteners must be clean and

dry.

8. Insert the cap screws (key 22), and tighten the

hex nuts (key 23) in the following manner. The first

four hex nuts tightened should be diametrically

opposed and 90 degrees apart. Tighten these four

hex nuts to 34 NSm (25 lbfSft).

9. Tighten the remaining hex nuts in a clockwise,

criss-cross pattern to 34 NSm (25 lbfSft).

10. Repeat this procedure by tightening four hex

nuts, diametrically opposed and 90 degrees apart, to

a torque of 68 NSm (50 lbfSft).

11. Tighten the remaining hex nuts in a clockwise,

criss-cross pattern to 68 NSm (50 lbfSft).