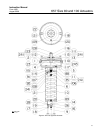

657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

12

block (keys 133, 183, 175, and 179) into the body as

shown in figure 6 and install support screws

(key 182).

3. Install handwheel and hex nut (keys 51 and 54).

4. Install a new handwheel gasket (key 185).

5. Mount the handwheel assembly on the

diaphragm casing, and secure with cap screws

(key 141).

6. Reconnect pressure tubing or piping to actuator

casing.

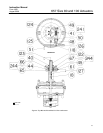

Size 100 Top-Mounted Handwheel

(Adjustable Up Travel Stop)

A top-mounted handwheel assembly is normally

used as an adjustable-up travel stop to limit full

retraction of the actuator stem. Clockwise rotation of

the handwheel (key 51) moves the actuator stem

(key 10) downward, compressing the spring (key 6).

Spring action returns the stem as the handwheel is

turned counterclockwise. Instructions are given

below for complete disassembly and assembly.

Perform the disassembly only as far as necessary to

accomplish the required maintenance; then, begin

the assembly at the appropriate step.

Key numbers refer to figure 5 for actuator parts and

figure 8 for handwheel parts.

Disassembly

1. Bypass the control valve. Reduce the loading

pressure to atmospheric (refer to the Maintenance

section), and remove the tubing or piping from the

diaphragm casing.

WARNING

To avoid personal injury from the

precompressed spring force thrusting

the upper diaphragm casing (key 1)

away from the actuator, relieve spring

compression (step 2, below), and

carefully remove casing cap screws

(key 124) (step 3, below).

2. Rotate handwheel counterclockwise, relieving all

spring compression.

3. Unscrew cap screws (key 124), and remove gear

case cover (key 123).

4. Loosen the set screws (key 41) in the front and

back worm retainers (keys 48 and 49) and

handwheel (key 51).

5. Remove retaining ring (key 118), and remove

handwheel.

6. Remove front and back worm retainers (keys 48

and 49).

7. Remove worm shaft (key 45).

8. Pull the power screw assembly (key 122). The

bearing and gear retainer, thrust bearing, and worm

gear (keys 66, 67 and 44) will come out with the

power screw.

Assembly

1. Pack the ball bearings (key 50) with lithium

grease lubricant (key 241), and insert one ball

bearing into the back worm retainer (key 49).

2. Thread the back worm retainer and ball bearing

into the gear case. Align the slot in the worm retainer

with the set screw hole in the gear case, insert set

screw (key 41), and tighten.

3. Coat the worm shaft (key 45) threads with lithium

grease lubricant, and slide the shaft into the gear

case so that the end of the shaft fits snugly in the

back worm retainer.

4. Insert the bearing into the front worm retainer

(key 48), and thread the retainer and ball bearing

into the gear case. Align the slot in the retainer with

the hole in the gear case, insert the set screw

(key 41), and tighten.

5. Slide the handwheel onto the worm shaft

(key 45), and install retaining ring (key 118).

6. Pack the two thrust bearings (key 67) with lithium

grease lubricant. Install one thrust bearing, then the

worm gear (key 44), followed by the second thrust

bearing and the bearing and gear retainer (key 66).

7. Coat the power screw threads (key 122) with

lithium grease lubricant. Slide the power screw into

the thrust bearing (key 67), turn the handwheel, and

feed the sleeve through the worm gear.

8. Adjust set screws (key 40) to eliminate free play

in the bearings.

Note

Over-tightening the set screws will

make handwheel operation difficult.

9. Install gear case cover (key 123), and tighten cap

screws (key 124).