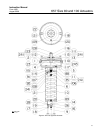

657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

4

is properly connected to the actuator. Refer to the

positioner instruction manual as necessary.

4. Cycle the actuator several times to check that the

valve stem travel is correct and that the travel occurs

when the correct pressure range is applied to the

diaphragm.

5. If valve stem travel is incorrect, refer to the Travel

procedure in the Adjustments section.

6. If the pressure range is incorrect, refer to the

Spring procedure in the Adjustments section.

Adjustments

Travel

Make travel adjustments when the motion observed

during actuator travel is different from the travel

stamped on the actuator nameplate. If the Actuator

Mounting procedure was followed correctly, this

adjustment should not be necessary.

When adjusting travel of a reverse-acting

(push-down-to-open) valve, apply a slight pressure

on the actuator diaphragm. This moves the valve

plug off the seat, reducing the chance of damaging

the valve plug or seat during adjustments.

1. Back the stem locknuts away from the stem

connector, and slightly loosen the stem connector

cap screws.

CAUTION

Do not use wrenches or other tools

directly on the valve stem. Damage to

the stem surface and subsequent

damage to the valve packing may

result.

2. Tighten the locknuts together, using a wrench,

then screw the valve stem either into the stem

connector to lengthen travel or out of the stem

connector to shorten travel.

3. Cycle the actuator to check the travel. If actual

travel is not equal to the specified travel, adjust and

check travel until correct. Tighten the stem

connector cap screws when correct travel is

obtained.

4. Raise the travel indicator disk by threading the

stem locknuts against the stem connector.

Spring

Make spring adjustments when the loading pressure

range applied to achieve specified travel is not equal

to the pressure range stamped on the actuator

nameplate. Refer to the Bench Set pressure range

on the nameplate when the valve contains no

pressure and the packing is loosely inserted in the

bonnet. Refer to the Max. Allow. Supply on the

nameplate when the valve is controlling the specified

pressure drop and the packing is tightened to stop

leaks around the stem.

Monitor loading pressure carefully when making

adjustments. Do not exceed the pressure

specifications of either the loading regulator or the

actuator casings.

Each actuator spring has a fixed pressure span.

Changing the spring compression shifts the span up

or down to make valve travel coincide with the

loading pressure range.

Size 80

Remove cover band (key 60, figure 4), insert a rod of

approximately 12.7 mm (1/2-inch) diameter into a

hole in the adjusting screw (key 12, figure 4), and

rotate the adjusting screw with the rod. Rotating the

screw from left to right will increase the loading

pressure required to start actuator stem travel;

opposite rotation will decrease the pressure required

to start travel.

Size 100

CAUTION

The actuator must be in the vertical

position when adjusting spring to

avoid damage to thrust bearing (key

35, figure 5) and to properly position

spacers required for adjustment.

Remove the shroud plate (key 107, figure 5), and

loosen the jam nut (key 115, figure 5).

For small spring forces, adjustments can be made

by rotating the adjusting nut (key 114, figure 5).

Clockwise rotation (when viewed from diaphragm

casings) of the adjusting nut will increase the loading

pressure required to start actuator stem travel, and

counterclockwise rotation will decrease the pressure

required to start travel. Tighten the jam nut when

adjustment is complete.