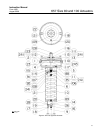

657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

11

flange so that the key engages the slot in the lower

sleeve. Secure adjusting flange with cap screws

(key 64).

9. Adjust set screws (key 40) to eliminate free play

in the bearings.

Note

Over-tightening the set screws will

make handwheel operation difficult.

10. Install the adjusting screw and thrust bearings

(keys 12 and 35). Pack bearings with lithium grease

lubricant (key 241), and install as shown in figure 7.

11. Slide the spring case (key 29) into position, and

secure with cap screws (key 62).

12. Complete steps 3 through 8 of the size 80

actuator assembly section.

Size 80 Hydraulic Snubber

The size 80 Type 657 is available with a hydraulic

snubber, as shown in figure 7, to dampen vertical

instability of actuator stem movement. The snubber

is adjusted by rotating the adjusting screws (key 83,

figure 7) counterclockwise out of the reservoir (key

79, figure 7) to increase damping action and

clockwise to decrease damping action. The adjusting

screw on the right (the lower of the two adjusting

screws in section B-B of figure 7) regulates

downward damping action, and the screw on the left

regulates upward damping action.

Size 80 Top-Mounted Handwheel

(Adjustable Up Travel Stop)

CAUTION

If repeated or daily manual operation is

expected, and the actuator is equipped

with a casing-mounted travel stop or

top-mounted handwheel, the

diaphragm could be subject to

excessive wear.

The actuator should be equipped with

a side-mounted handwheel, which is

designed for more frequent use as a

manual operator.

A top-mounted handwheel assembly is normally

used as an adjustable-up travel stop to limit full

retraction of the actuator stem. Turning the

handwheel clockwise turns the handwheel stem

(key 133, figure 6) into the diaphragm casing and

forces the pressure block assembly (key 179,

figure 6) against the diaphragm and diaphragm

plate. Instructions are given below for complete

disassembly and assembly. Perform the

disassembly only as far as necessary to accomplish

the required maintenance; then, begin the assembly

at the appropriate step.

Key numbers refer to figure 4 for actuator parts and

figure 6 for handwheel parts.

Disassembly

1. Bypass the control valve. Reduce the loading

pressure to atmospheric, and remove the tubing or

piping from the diaphragm casing (key 1).

WARNING

To avoid personal injury from the

precompressed spring force thrusting

the upper diaphragm casing (key 1)

away from the actuator, relieve spring

compression (step 2, below), and

carefully remove casing cap screws

(key 141) (step 3, below).

2. Remove cover band (key 60). Insert a rod of

approximately 12.7 mm (1/2-inch) diameter into a

hole in the adjusting screw (key 12), and rotate the

adjusting screw from right to left until spring

compression is relieved. Rotate handwheel to be

sure it is not compressing actuator spring.

3. Unscrew cap screws (key 141), and remove

handwheel assembly.

4. Remove hex nut (key 54), and lift off the

handwheel.

5. Unscrew support screws (key 182), and remove

pressure block, stem, stem collar, and thrust bearing

(keys 179, 133, 183, and 175).

6. Unscrew body nut (key 186), and remove gland

(key 180). If necessary, remove and replace packing

rings (key 181).

Assembly

1. Install new packing rings and gland (keys 181

and 180), and thread the body nut (key 186) onto the

body.

2. Lubricate the thrust bearing and stem (keys 175

and 133), with lithium grease lubricant (key 241).

Slide stem, stem collar, thrust bearing, and pressure