657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

6

sure the actuator cannot suddenly

open or close the valve.

D Use bypass valves or completely

shut off the process to isolate the

valve from process pressure. Relieve

process pressure from both sides of

the valve. Drain the process media

from both sides of the valve.

D Vent the power actuator loading

pressure and relieve any actuator

spring precompression.

D Use lock-out procedures to be

sure that the above measures stay in

effect while you work on the

equipment.

D The valve packing box may

contain process fluids that are

pressurized, even when the valve has

been removed from the pipeline.

Process fluids may spray out under

pressure when removing the packing

hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

The maintenance instructions are divided into four

sections: actuator (sizes 80 and 100); side-mounted

handwheel assembly (manual operator); hydraulic

snubber; and top-mounted handwheel assembly

(adjustable-up travel stop).

Actuator

This procedure describes how the actuator can be

completely disassembled and assembled. When

inspection or repairs are required, disassemble only

those parts necessary to accomplish the job; then,

start the assembly at the appropriate step.

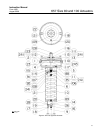

Key numbers refer to figure 4 for size 80 actuators

and figure 5 for size 100 actuators.

Size 80 Disassembly

1. Bypass the control valve. Reduce the loading

pressure to atmospheric, and remove the tubing or

piping from the top of the diaphragm casing (key 1).

WARNING

To avoid personal injury from the

precompressed spring force thrusting

the upper diaphragm casing (key 1)

away from the actuator, relieve spring

compression (step 2, below), and

carefully remove casing cap screws

(key 22) (step 4, below).

2. Remove cover band (key 60). Insert a rod of

approximately 12.7 mm (1/2-inch) diameter into a

hole in the adjusting screw (key 12), and rotate the

adjusting screw from right to left until spring

compression is relieved. If the actuator has a

handwheel, rotate it counterclockwise, relieving all

spring compression.

3. If necessary, the entire actuator may be removed

from the valve body by unscrewing two cap screws

from stem connector (key 26) and removing

actuator-to-bonnet bolting.

4. Unscrew diaphragm casing cap screws and nuts

(keys 22 and 23), and lift off upper diaphragm casing

(key 1).

5. Remove the molded diaphragm (key 2).

6. For actuators without snubber, remove

diaphragm plate and stem (keys 4 and 10) as an

assembly. This assembly can be broken down

further, if necessary, by removing the cap screw

(key 3).

7. For actuators with snubber (see figure 7),

unscrew cap screw (key 3), and remove diaphragm

plate (key 4). Remove stem connector (key 26).

Unscrew cap screws (key 85), and remove cylinder

assembly (key 74) and attached stem and upper

seat (keys 10 and 90) from actuator.

To disassemble snubber:

a. Unscrew stem from piston/piston rod

assembly (key 27).

b. Remove retaining rings, cylinder heads, and

piston/piston rod assembly (keys 76, 75, and 27).

Replace packing and O-rings (keys 103, 104, 77

and 105) as required.

8. Remove actuator spring, upper sleeve, and

spring seat (keys 6, 34 and 11).