657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

10

12. After the last hex nut is tightened to 68 NSm (50

lbfSft), all of the hex nuts should be tightened again

to 68 NSm (50 lbfSft) in a circular pattern around the

bolt circle.

13. Once completed, no more tightening is

recommended.

14. Install the actuator stem extension (key 116),

diaphragm casing cover O-rings (keys 112 and 113),

and seal bushing (key 111). Install the gear case

cover (key 123) or the handwheel assembly (see

figure 8).

15. Mount the actuator on the valve, and secure

with the actuator-to-bonnet bolting. Refer to the

Installation section to connect actuator stem to valve

plug stem.

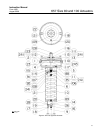

Size 80 Side-Mounted Handwheel

The side-mounted handwheel assembly (figure 7) is

normally used as a manual operator. The handwheel

can be mounted in either of two positions so that,

regardless of valve plug action, counterclockwise

rotation always opens the valve. The assembly is a

continuously connected type with an indicator to

show neutral position. By rotating handwheel away

from neutral, the handwheel can be used to limit

travel in either direction but not both directions at the

same time.

A grease fitting is provided on the gear box for

periodic gear lubrication with a general-purpose

grease.

Instructions are given below for complete

disassembly and assembly. Perform the

disassembly only as far as necessary to accomplish

the required maintenance; then, begin the assembly

at the appropriate step.

Key numbers refer to figure 7.

Disassembly

1. Complete steps 1 through 9 of the disassembly

portion of the size 80 actuator section.

2. Unscrew cap screws (key 64), and remove

adjusting flange (key 36). Do not lose the key

(key 47).

3. Unscrew the two screws (key 28), and remove

travel stop indicator (key 58) from lower sleeve

(key 46).

4. Turn handwheel (key 51) to raise lower sleeve.

Continue turning handwheel until lower sleeve is free

of worm gear (key 44). Lift out lower sleeve, bearing

and gear retainer, thrust bearings, and worm gear

(keys 46, 66, 67, and 44).

5. The worm shaft (key 45) and associated parts

can be removed in order to replace or lubricate

them. First, remove the handwheel cap (key 54) and

the handwheel (key 51). Do not lose the small ball or

spring (keys 55 and 56).

6. Loosen the two set screws (key 41), and unscrew

the two worm retainers (keys 48 and 49). The ball

bearings (key 50) will come out with the retainers.

Remove the worm shaft (key 45).

Assembly

1. Pack the ball bearings (key 50) with lithium

grease lubricant, and insert one ball bearing in the

back worm retainer (key 49) as shown in figure 7

(section C-C).

2. Thread the back worm retainer and ball bearing

(keys 49 and 50) into the gear case. Align the slot in

the worm retainer with the set screw hole in the gear

case, insert the set screw (key 41), and tighten it.

3. Coat the worm shaft (key 45) threads with

anti-seize lubricant (key 244), and slide the shaft into

the gear case so that the end of the shaft fits snugly

in the back worm retainer.

4. Insert the bearing in the front worm retainer

(key 48), and thread the retainer and ball bearing

into the gear case. Align the slot in the retainer with

the set screw hole in the gear case, insert the set

screw (key 41), and tighten it.

5. Put the spring and ball (keys 56 and 55) in the

handwheel (key 51). Slide the handwheel onto the

worm shaft (key 45). Thread the handwheel cap

(key 54) onto the worm shaft.

6. Pack the two thrust bearings (key 67) with lithium

grease lubricant. Install one thrust bearing; then,

install the worm gear (key 44) followed by the

second thrust bearing and the bearing and gear

retainer (key 66).

7. The lower sleeve (key 46) has two screw holes in

one end. Coat the sleeve threads with lithium grease

lubricant, slide the end of the lower sleeve with the

holes into the thrust bearing (key 67), turn the

handwheel, and feed the sleeve through the worm

gear. Continue turning the handwheel until the lower

sleeve protrudes from the gear case. Fasten the

travel stop indicator (key 58) to the sleeve with the

two machine screws (key 28).

8. Install the key (key 47) on the adjusting flange

(key 36). Coat the adjusting flange threads with

anti-seize lubricant (key 244). Install the adjusting