15 Undo the retaining strap bolt and

withdraw the filter from its location bracket.

Disconnect the inlet and supply hose from the

filter. If crimp connectors are fitted they will

have to be cut free and new screw type clips

fitted (photo).

16 Connect the hoses to the new filter

ensuring that the filter is correctly orientated

(the arrow mark on the body indicates the

direction of fuel flow). Ensure that the hose

clips are secure before refitting the filter into

the retaining strap and securing the retaining

bolt. When the engine is restarted, check the

hose connections to ensure that there is no

fuel leakage from them.

Air cleaner element -

renewal ¡

17 Release the spring clip each side at the

front of the air cleaner, then unscrew and

remove the two screws from the top front face

of the housing. Withdraw the end cover and

element from the filter unit (photos).

18 Wipe any dirt from within the casing then

locate the new element and refit it together

with the end cover.

Idle speed and mixture

adjustment ∞

19 No manual idle speed and/or mixture

adjustments to this type of fuel system are

necessary or possible. Any such adjustments

are automatically made by the ECU. If the

engine idle speed and/or mixture adjustment

is suspect, it must be checked using CO

measuring equipment; a task best entrusted

to a FIAT dealer or a competent garage. The

most probable cause of a malfunction is likely

to be a defective sensor or incorrectly

adjusted accelerator control cable.

Accelerator control system

- check and adjustment #

20 To check the adjustment of the

accelerator control system, it is essential that

the engine is at its normal operating

temperature. This is achieved by running the

engine for a period of about fifteen minutes,

by which time the cooling fan should have cut

into operation several times. At this point,

stop the engine, turn the ignition key to the

OFF position and proceed as follows.

21 Remove the air cleaner unit.

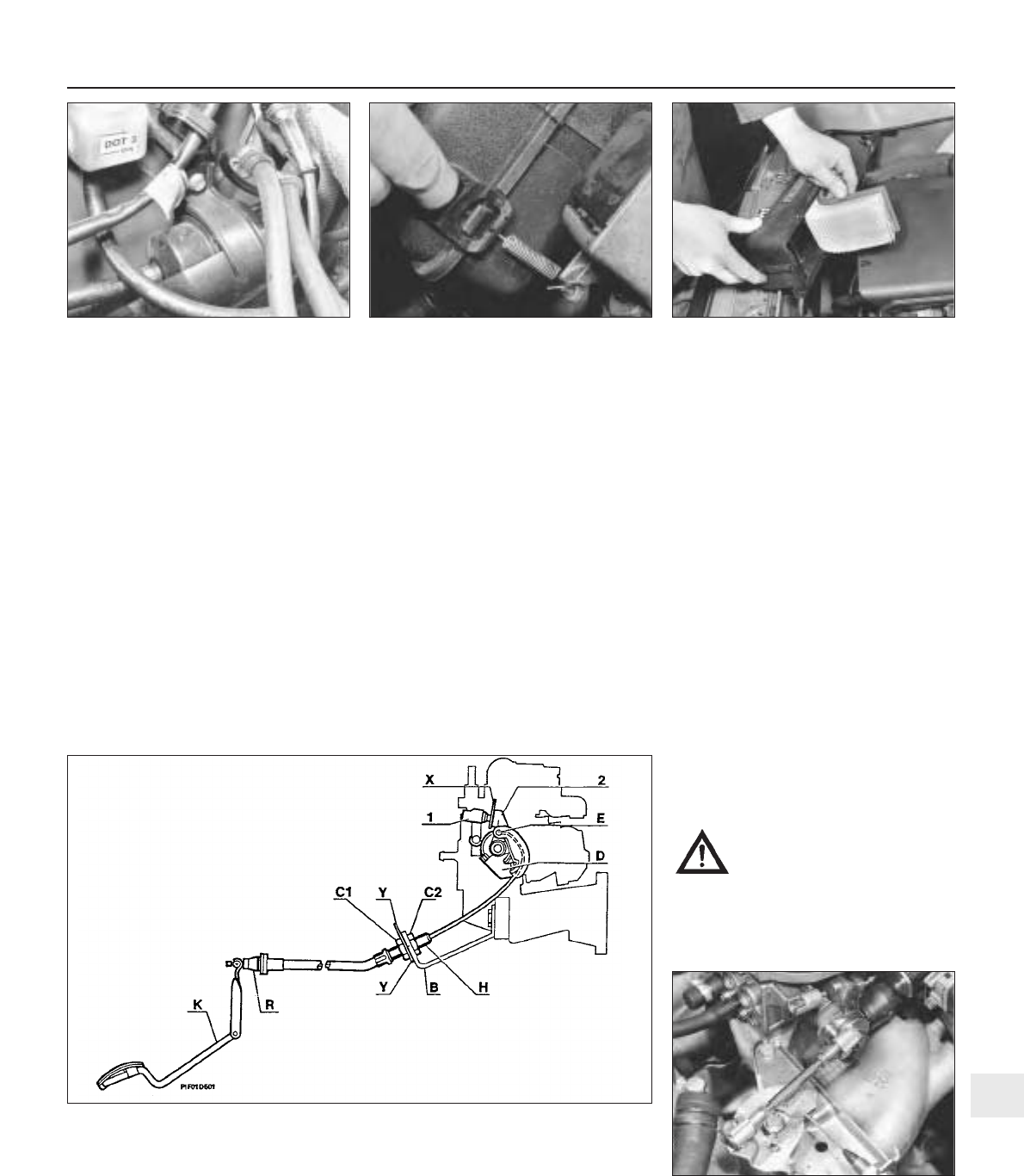

22 Place a 10 mm shim (X) between the

adjustment screw and the cam lever (between

items 1 and 2 in Fig. 13.47), on the throttle

body. This will open the thottle butterfly by

20º.

23 Loosen off the locknuts (C1 and C2) from

each linkage end. Insert another 10 mm

shim (Y) between the cable support bracket

and the nut (C1). Carefully tighten the nut

against the shim, ensuring that the cam does

not move whilst making the cable slightly taut.

24 Remove the shim (Y) and carefully tighten

the nut (C2) against the bracket without

allowing the nut (C1) to move. Remove the

shim (X) and release the accelerator pedal.

Check that the butterfly is completely open

when the the pedal is fully depressed.

Fuel system

depressurisation ¡

Warning: Refer to the beginning

of this Section before starting

any work.

25 The fuel system should always be

depressurised whenever any fuel hoses

and/or system components are disconnected

and/or removed. This can easily be achieved

as follows.

Supplement: Revisions and information on later models 13•75

9D.17B . . . remove the cover and extract

the element

9D.17A Release the air cleaner end cover

retaining clips . . .

9D.15 Secondary fuel filter element

9D.22 Accelerator control rod and cable

connections

A Cable

B Bracket

C1 Locknut

C2 Locknut

D Pulley

E Pawl

H Protection

K Pedal

R Bush

X Shim

Y Shim

1 Adjustment screw

2 Cam lever

13

Fig. 13.47 Accelerator linkage and butterfly control lever - SPi models (Sec 9D)