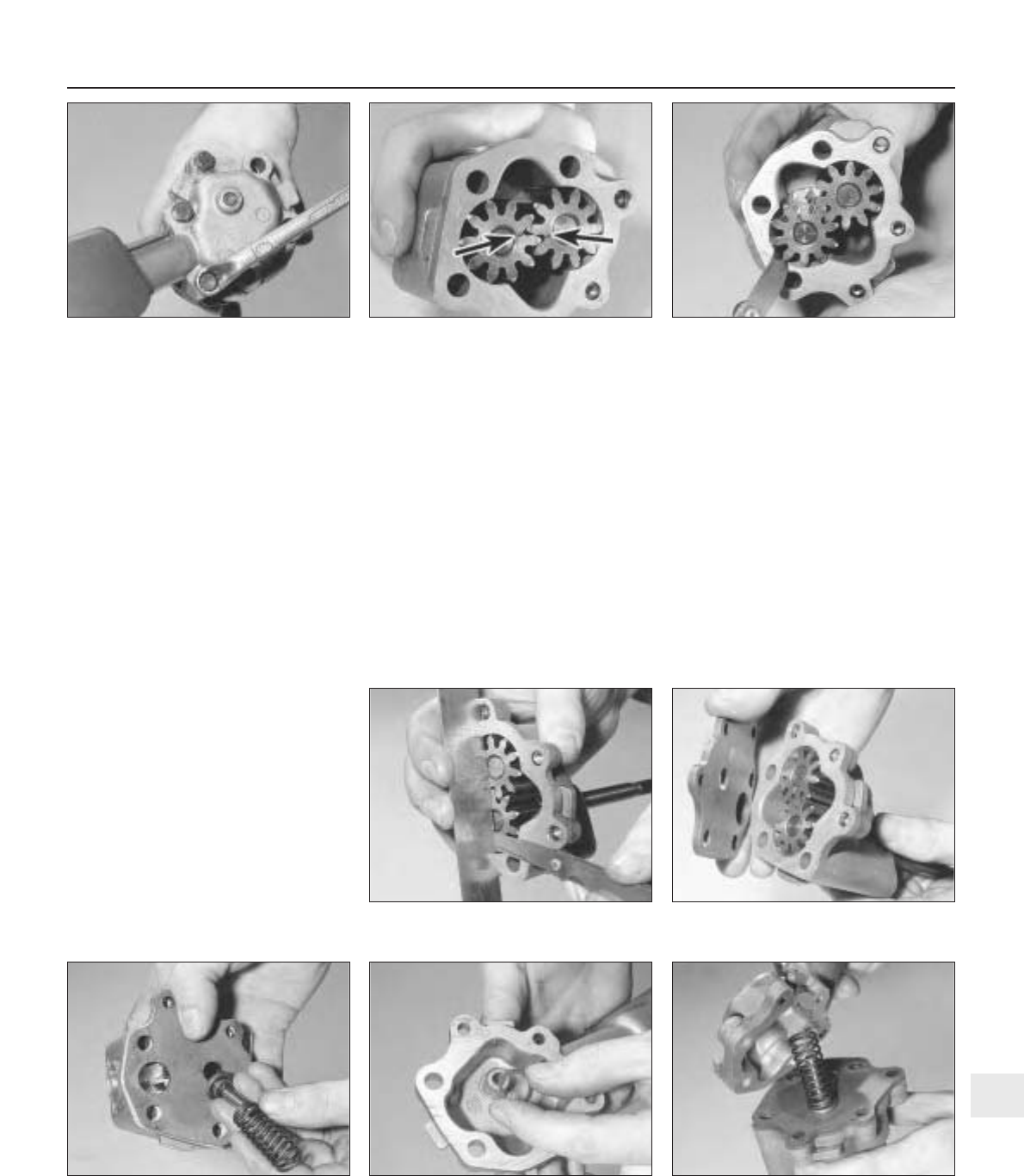

173 Lift the intermediate plate from the oil

pump body.

174 The gears can now be removed from the

oil pump body. Inspect them for obvious signs

of wear or damage, and renew if necessary.

175 Commence reassembly by lubricating

the gears with clean engine oil, and refitting

them to the casing. Note that the scribed

marks on the top faces of the gears should

face each other with the gears installed

(photo).

176 Using a feeler gauge, check that the

clearance between the gears and the pump

body is within the limits given in the Specifica-

tions (photo).

177 Using a straight-edge placed across the

top of the pump body and the gears, and a

feeler gauge, check that the gear endfloat is

within the limits given in the Specifications

(photo).

178 If either the gear-to-body clearance, or

the gear endfloat is outside the specified

limits, both gears should be renewed.

179 Locate the intermediate plate on the

pump body (photo).

180 Place the pressure relief valve and spring

over the pressure relief hole in the

intermediate plate, and locate the spring seat

over the boss in the pump cover, then refit the

pump cover, ensuring that the pressure relief

valve components seat correctly (photos).

181 Refit and tighten the pump cover

securing bolts.

182 Thoroughly clean the mating faces of the

pump and crankcase before refitting the

pump. Prime the pump by injecting clean

engine oil into it and turning it by hand.

183 Fit the pump using a new gasket, then

insert the securing bolts and tighten them.

184 Refit the sump and top up the engine oil

level.

Pistons/connecting rods -

removal and refitting #

185 Remove the sump and the cylinder head

as described previously in this Section.

186 The big-end caps and connecting rods

normally have identification marks stamped

into their sides, facing the coolant pump side

of the cylinder block. If no marks are present,

use a centre-punch to identify the bearing

caps and the connecting rods for location.

187 Turn the crankshaft so that No. 1

crankpin is at its lowest point, then unscrew

the nuts and tap off the bearing cap. Keep the

bearing shells in the cap and the connecting

rod if they are to be re-used, taping them in

position if necessary to avoid loss.

188 Using the handle of a hammer, push the

piston and connecting rod up the bore and

withdraw it from the top of the cylinder block.

Loosely refit the cap to the connecting rod.

189 Repeat the procedure given in

paragraphs 187 and 188 on No. 4 piston and

connecting rod, then turn the crank-

shaft through half a turn and repeat the

procedure on Nos 2 and 3 pistons and

connecting rods.

190 The pistons and connecting rods and the

big-end bearings can be examined and if

Supplement: Revisions and information on later models 13•47

7B.176 Check gear-to-body clearance7B.175 Correct alignment of scribed marks

(arrowed) on gears

7B.171 Undo the oil pump cover bolts

7B.180C . . . then fit the cover7B.180B Locate spring seat over boss

within pump cover . . .

7B.179 Refitting the intermediate plate7B.177 Checking the gear endfloat

7B.180A Locate pressure relief valve and

spring on the intermediate plate

13