98 Commence reassembly by liberally oiling

the bearings in the housing, and the oil seal lip.

99 Carefully insert the camshaft into the

housing from the blanking plate/distributor

end, taking care to avoid damage to the

bearings.

100 Refit the blanking plate using a new

gasket.

101 Refit the camshaft housing as described

previously in this Section.

Cylinder head

(1372 cc ie engine) -

removal and refitting #

Note: The following instructions describe

cylinder head removal and refitting leaving the

camshaft, manifolds and associated items in situ

In the head. If required, these items can be

removed separately. When removing the

cylinder head the engine must be cold - do not

remove the head from a hot engine. A new

cylinder head gasket and any associated gaskets

must be used during reassembly. FIAT specify

that the main cylinder head bolts should be

renewed after they have been used (ie tightened)

four times. If in any doubt as to the number of

times that they have been used renew them as a

precaution against possible failure.

Warning: Refer to the beginning

of Section 9 before starting any

work.

102 Depressurise the fuel supply system as

described in Section 9 of this Chapter.

103 Disconnect the battery negative lead.

104 Drain the engine coolant as described in

Section 8.

105 Remove the air cleaner unit as described

in Section 9.

106 Remove the timing belt as described

previously in this Section.

107 Disconnect the crankcase ventilation

hose from the cylinder head and the SPi

injector unit.

108 Disconnect the accelerator cable at the

engine end.

109 Detach the engine idle speed check

actuator lead, the inlet manifold vacuum

sensor lead, the coolant temperature sensor

lead, the injector supply lead, the throttle

position switch lead and the distributor cap

(with HT leads). Position them out of the way.

110 Disconnect the brake servo hose from

the manifold.

111 Disconnect the coolant hoses from the

thermostat and the inlet manifold.

112 Slowly release the fuel supply and return

hose retaining clips and detach the hoses

from the injector unit housing and

connections. Catch any fuel spillage in a clean

cloth and plug the hoses to prevent the

ingress of dirt and further fuel loss.

113 Unbolt and detach the exhaust downpipe

from the manifold.

114 Loosen off the cylinder head retaining

bolts in a progressive manner, reversing the

sequence shown in Fig. 13.17. When all of the

bolts are loosened off, extract them and

collect the washers.

115 Check that all fittings and associated

attachments are clear of the cylinder head,

then carefully lift the head from the cylinder

block. If necessary tap the head lightly with a

soft-faced mallet to free it from the block, but

do not lever it free between the joint faces.

Note that the cylinder head is located on

dowels.

116 Recover the old cylinder head gasket and

discard it.

117 Clean the cylinder head and block mating

surfaces by careful scraping. Take care not to

damage the cylinder head - it is manufactured in

light alloy and is easily scored. Cover the coolant

passages and other openings to prevent dirt and

carbon from falling into them. Mop out all the oil

from the cylinder head bolt holes - if oil is left in

them, hydraulic pressure, caused when the bolts

are refitted, could cause the block to crack.

118 If required the cylinder head can be

dismantled and overhauled as described in

paragraphs 129 to 131 of this Section.

119 The new gasket must be removed from

its protective packing just before it is fitted.

Do not allow any oil or grease to come into

contact with the gasket. Commence refitting

the cylinder head by locating the new gasket

on the cylinder block so that the word “ALTO”

is facing up (photo).

120 With the mating faces scrupulously

clean, refit the cylinder head into position and

engage it over the dowels. Refer to the note at

the beginning of this part of the Section, then

refit the ten main cylinder head bolts and

washers. Screw each bolt in as far as possible

by hand to start with. Do not fit the smaller

(M8 x 1.25) bolts at this stage (photos).

121 The bolts must now be tightened in stages

and in the sequence shown in Fig. 13.17. Refer

to the specified torque wrench settings and

tighten all bolts to the Stage 1 torque, then

using a suitable angle gauge, tighten them to

the second stage, then the third stage (photos).

122 With the main cylinder head bolts fully

Supplement: Revisions and information on later models 13•43

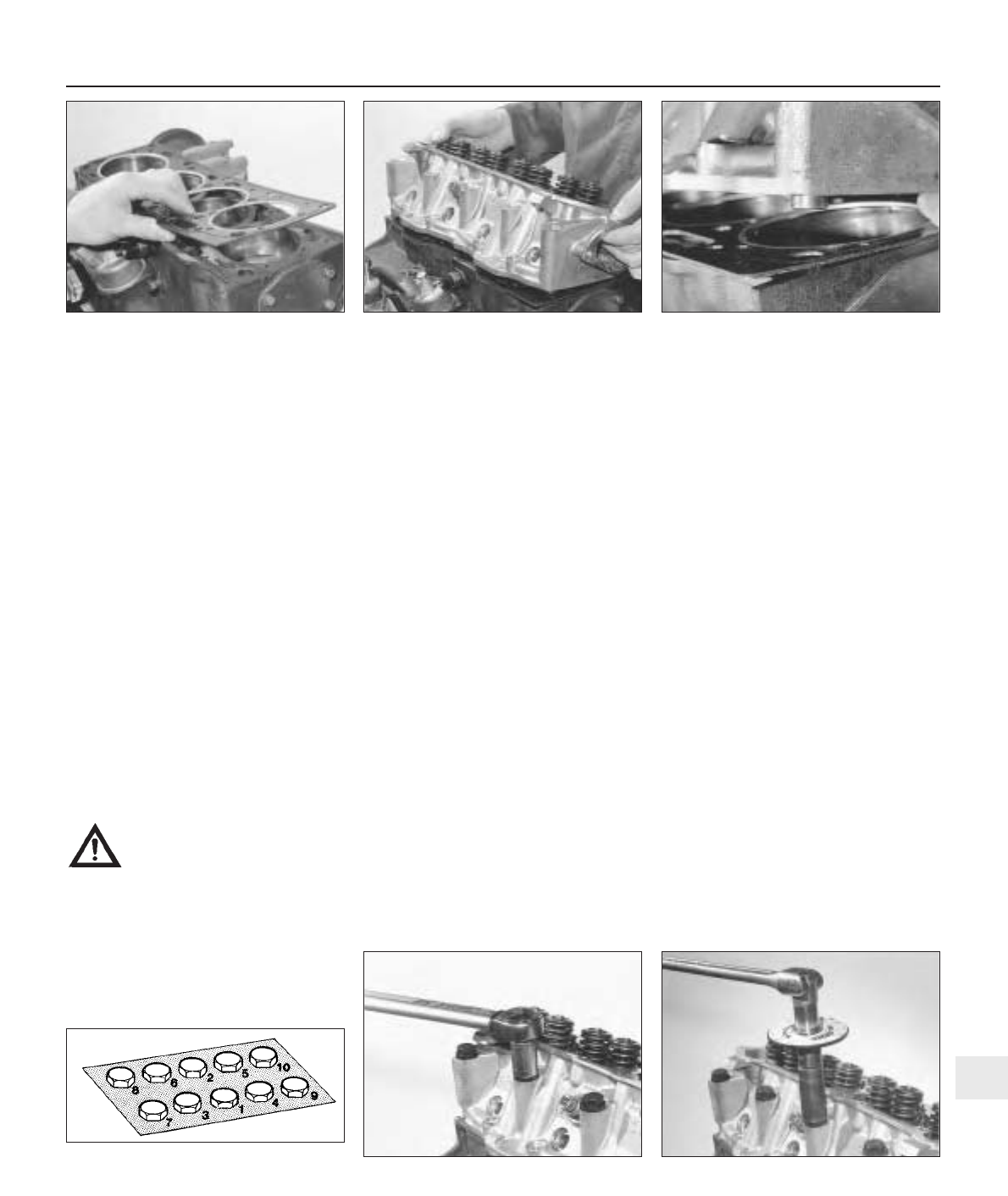

7B.120B . . . and engage the positioning

dowels in their holes

7B.120A Lower the cylinder head onto the

block . . .

7B.119 Locating a new cylinder head

gasket on the cylinder block (engine

shown on dismantling stand)

7B.121A Tighten main cylinder head bolts

to specified torque . . .

Fig. 13.17 Cylinder head bolt tightening

sequence on the 1372 cc ie and Turbo ie

engines (Sec 7B)

13

7B.121B . . . and then through the specified

angle