depressurize the fuel system, before

disconnecting the fuel pipes and removing the

throttle body, as described in Section 9D.

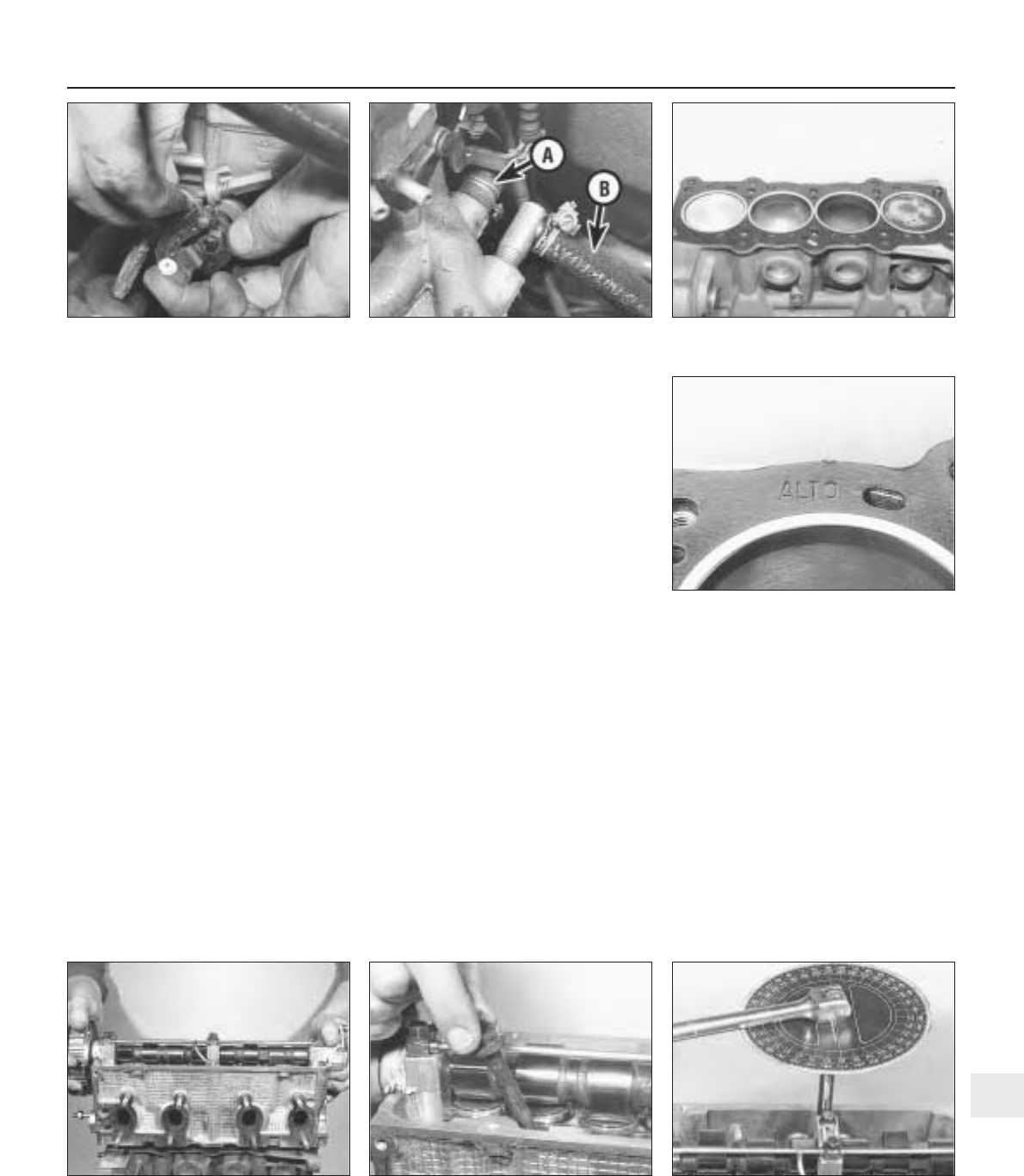

34 Disconnect the coolant and vacuum

hoses from the cylinder head and inlet

manifold (photo).

35 Disconnect the electrical lead from the

coolant temperature switch, the LT leads from

the distributor and the idle cut-off solenoid

lead.

36 Remove the distributor cap, disconnect

the plug leads and place the cap and leads to

one side of the engine compartment.

37 Unbolt and remove the timing belt cover.

38 Set No. 4 piston to TDC and then release

the timing belt tensioner and slip the belt from

the camshaft and coolant pump sprockets.

39 Unbolt and remove the inlet manifold,

complete with carburettor, or throttle body as

applicable.

40 Unbolt the exhaust manifold from the

cylinder head and tie it to one side of the

engine compartment; the downpipe bracket

will have to be disconnected.

41 Unscrew the cylinder head bolts, a half

turn at a time in the reverse order to that

shown in Fig. 1.30 of Chapter 1. When the

bolts are free, remove them with their

washers.

42 Lift the cylinder head from the block. If it is

stuck tight, insert pieces of wood into the

exhaust or inlet ports and use them as levers

to “rock” the head off the block. On no

account drive levers into the gasket joint or

attempt to tap the head sideways as it is

located on positioning dowels.

43 Remove and discard the cylinder head

gasket and both manifold gaskets.

44 The cylinder head can be dismantled after

removing the camshaft and cam followers as

described in the preceding sub-Section.

45 Further dismantling and decarbonising are

described in Chapter 1, Section 39. Note that

single valve springs are used.

46 If the valves have been ground in, the

valve clearances will require adjusting, as

described previously. This should be done

before the cylinder head is refitted to the

engine.

47 Before refitting the assembled cylinder

head, make sure that the head and block

mating surfaces are perfectly clean, and that

the block bolt holes have been cleared of any

oil.

48 The camshaft sprocket timing mark must

be aligned with the one on the cylinder head.

49 The new gasket should not be removed

from its nylon cover until required for use. Fit

the gasket dry to perfectly clean surfaces.

50 Place the gasket on the cylinder block so

that the word ALTO can be read from above

(photos).

51 Lower the cylinder head onto the block so

that it locates on the positioning dowels

(photo).

52 The cylinder head bolts must have clean

threads, dipped in engine oil and allowed to

drain for thirty minutes. Screw the bolts in

finger-tight and then tighten them in the

sequence shown in Fig. 1.30 of Chapter 1,

and in the stages specified (see Specification)

(photos).

53 Refit the inlet manifold and carburettor

using a new gasket.

54 Reconnect the exhaust manifold using a

new gasket. Tighten all nuts to the specified

torque. Reconnect the exhaust downpipe

bracket.

55 Reconnect the timing belt and tension it

as described earlier.

56 Refit the timing belt cover and the

distributor cap and camshaft cover.

57 Reconnect all hoses, electrical leads and

controls.

58 Fit the air cleaner.

59 Fill and bleed the cooling system.

Supplement: Revisions and information on later models 13•23

5B.50A Cylinder head gasket5B.34 Inlet manifold coolant hose (A) and

brake servo vacuum hose (B)

5B.32 Disconnecting the throttle cable

5B.52B Typical disc for angular tightening

of cylinder head bolts

5B.50B Cylinder head gasket top surface

marking

5B.52A Inserting a cylinder head bolt5B.51 Fitting the cylinder head

13