Note: Before diagnosing steering faults, be

sure that trouble is not due to incorrect or

uneven tyre pressures, inappropriate tyre

combinations, or braking system or

suspension defects.

Car pulls to one side

ⅥⅥ Incorrect steering geometry

ⅥⅥ Collision damage

Vibration at steering wheel

ⅥⅥ Roadwheels out of balance or loose

ⅥⅥ Tyre damage

ⅥⅥ Loose driveshaft-to-hub nuts

Car wanders

ⅥⅥ Play in steering gear

ⅥⅥ Wear in steering balljoints

Heavy or stiff steering

ⅥⅥ Lack of lubricant in steering gear or balljoints

ⅥⅥ Incorrect steering geometry

ⅥⅥ Collision damage

Play at steering wheel

ⅥⅥ Wear in steering rack or balljoints

ⅥⅥ Loose steering shaft coupling pinch-bolt or

worn splines

ⅥⅥ Worn steering column/shaft universal joints

Rattles from steering

ⅥⅥ Steering damper defective or in need of

adjustment

ⅥⅥ Loose steering column mounting bolts

ⅥⅥ Loose steering column/shaft coupling

pinch-bolts

ⅥⅥ Loose steering rack housing mounting bolts

ⅥⅥ Worn steering shaft bushes

Excessive or uneven tyre wear

ⅥⅥ Incorrect steering geometry

ⅥⅥ Worn steering components

ⅥⅥ Collision damage

wear. Before considering the steering angles,

check that the tyres are correctly inflated, that

the front wheels are not buckled, the hub

bearings are not worn or incorrectly adjusted

and that the steering linkage is in good order,

without slackness or wear at the joints.

2 Wheel alignment consists of four factors:

Camber, is the angle at which the road

wheels are set from the vertical when viewed

from the front or rear of the vehicle. Positive

camber is the angle (in degrees) that the wheels

are tilted outwards at the top from the vertical.

Castor, is the angle between the steering

axis and a vertical line when viewed from each

side of the vehicle. Positive castor is indicated

when the steering axis is inclined towards the

rear of the vehicle at its upper end.

Steering axis inclination, is the angle when

viewed from the front or rear of the vehicle

between vertical and an imaginary line drawn

between the upper and lower suspension

strut mountings.

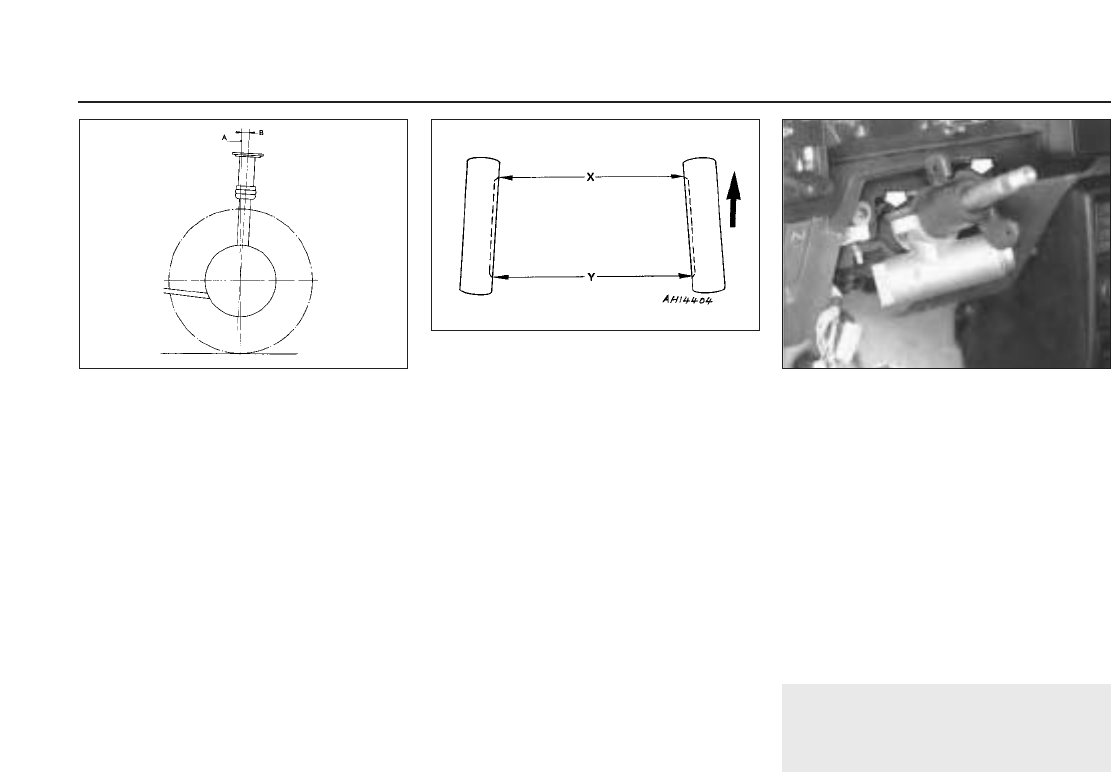

Toe, is the amount by which the distance

between the front inside edges of the

roadwheel rims differs from that between the

rear inside edges.

3 If the distance between the front edges is

less than that at the rear, the wheels are said

to toe-in. If the distance between the front

inside edges is greater than that at the rear,

the wheels toe-out.

4 Camber and castor are set during

production of the car and are not adjustable.

Any deviation from specification will be due to

collision damage or to gross wear in the

components concerned.

5 To check the front wheel alignment, first

make sure that the lengths of both tie-rods are

equal when the steering is in the straight-ahead

position. Measure between the locknut at the

balljoint and the ball cup at the end of the rack

housing by passing a thin rod under the rack of

the gaiter. If adjustment is required, release the

locknut and turn the tie-rod.

6 Obtain a tracking gauge. These are

available in various forms from accessory

stores or one can be fabricated from a length

of steel tubing suitably cranked to clear the

sump and bellhousing and having a setscrew

and locknut at one end.

7 With the gauge, measure the distance

between the two wheel inner rims (at hub

height) at the rear of the wheel. Push the

vehicle forward to rotate the wheel through

180º (half a turn) and measure the distance

between the wheel inner rims, again at hub

height, at the front of the wheel. This last

measurement should differ from (be less than)

the first by the appropriate toe-in according to

the Specification (see Specifications Section).

8 Where the toe-in is found to be incorrect,

release the tie-rod balljoint locknuts and turn

the tie-rods equally. Only turn them a quarter

of a turn at a time before re-checking the

alignment. Viewed from the centre line of the

car, turning the tie-rod clockwise will

decrease the toe-in.

9 Make sure that the gaiter outboard clip is

released otherwise the gaiter will twist as the

tie-rod is rotated.

10 Always turn both rods in the same

direction when viewed from the centre line of

the vehicle otherwise the rods will become

unequal in length. This would cause the

steering wheel spoke position to alter and

cause problems on turns with tyre scrubbing.

11 On completion, tighten the tie-rod balljoint

locknuts without altering their setting. Check

that the balljoint is at the centre of its arc of

travel and then retighten the gaiter clip.

9 Steering column lock -

removal and refitting

1

1 Remove the steering wheel and column

shrouds as described in Section 5, also the

steering column combination switch.

2 Unscrew and remove the steering column

mounting bolts and lower the column to

expose the lock shear bolts.

3 Drill out the bolts or extract them using an

extractor.

4 Refer to Chapter 4 for details of separation

of the ignition switch from the lock section.

5 When fitting the new lock, tighten the shear

bolts until their heads break off.

6 Bolt up the column, fit the combination

switch, shrouds and steering wheel and

tighten all nuts and bolts to the specified

torque.

10•4 Steering

Fig. 10.9 Steering column lock shear bolts

(arrowed) (Sec 9)

Fig. 10.8 Front wheel alignment diagram

(Sec 8)

X Front dimension Y - X = Toe-in

Y Rear dimension

Fig. 10.7 Castor angle (Sec 8)

A Vertical line B Castor angle (positive)

Fault finding - steering