2001 Edelbrock Corporation

Brochure No. 63-0020

©

Rev. 10/01

Page 19 of 27

3.7 Microswitch Installation and Wiring (Continued)

The bolts used to attach the microswitch have extra length to allow for spacing the microswitch away from

the bracket to offer a level of adjustability of the microswitch. After determining the position of the

microswitch, we recommend trimming the bolts for a clean installation.

Due to the wide variety of throttle linkage combinations in use, it is impossible to supply a microswitch

bracket custom-tailored to each application. The universal bracket-supplied will need to be modified to fit

your specific application.

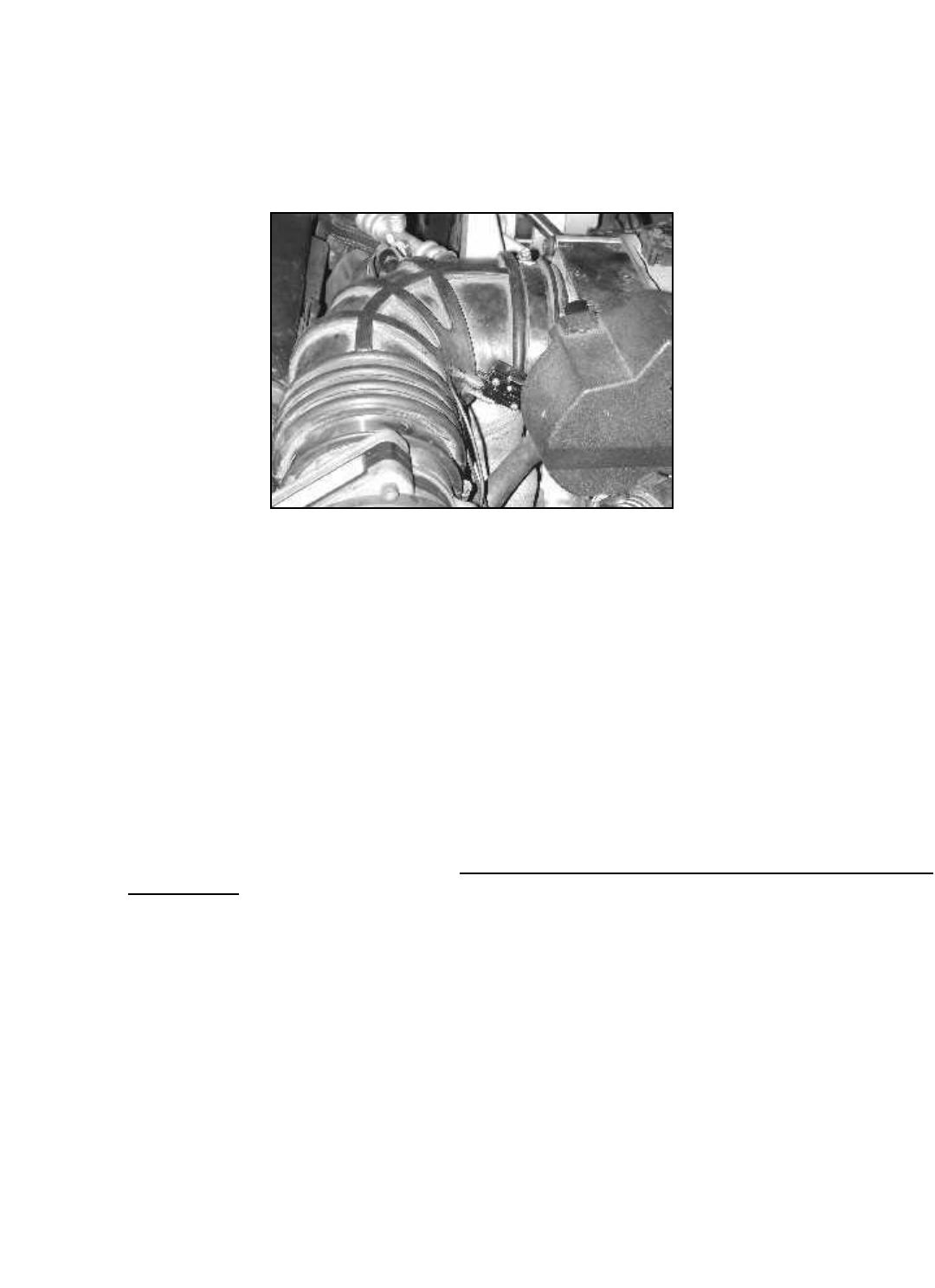

Here is the microswitch assembly mounted for use. It is an example of one of many ways in

which to mount a microswitch on your manifold. The microswitch bracket allows for many

different mounting positions. The microswitch bracket can be modified to clear almost any

potential interference around the throttle linkage.

Please look for potential microswitch mounting locations and adapt your microswitch bracket according to

the needs of your particular application.

The microswitch bracket is drilled to allow many different switch mounting positions. This flexibility allows

the microswitch to be positioned in such a manner that it will engage the throttle linkage without interfering

with its normal and safe operation. The bracket may be manipulated (bent, twisted, and/or cut) to best

suit your combination. Mount the microswitch so the actuation arm is triggered by throttle linkage making

sure all wiring and the bracket do not interfere with the smooth and safe operation of the throttle linkage.

Adjust microswitch to ensure the actuation arm “clicks” at the same point your throttle linkage reaches

wide open throttle against the throttle stop. At no time should the microswitch be enabled before wide

open throttle.