8

3

PISTON, RINGS AND CONNECTING ROD INSPECTION AND ASSEMBLY

2. Check piston pin bearing, Fig. 7.

Engine Models: 432447, 522447, 582447

a. Replace if greater than 18.03 mm (0.710”) or

.01 mm (.0004”) out of round.

Engine Models: 58A447, 588447

b. Replace if greater than 21.03 mm (0.828”) or

.01 mm (.0004”) out of round.

Fig. 7 – Checking Piston Pin Bearing

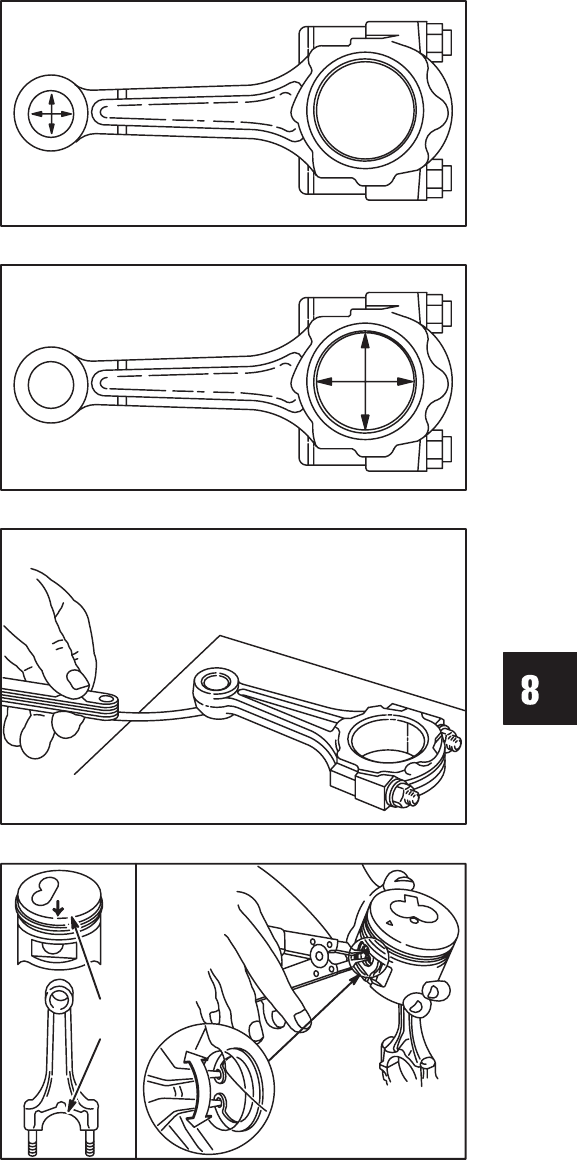

3. Check crankpin bearing end of connecting rod for

out of round, Fig. 8.

a. With bearing inserts removed, assemble

connecting rod cap and torque to 36.0 Nm

(320 in. lbs.).

Maximum out of round: 0.02 mm (0.0008”)

b. If out of round exceeds specification shown,

the connecting rod must be replaced.

Fig. 8 – Checking Crankpin Bearing End

4. Check for bent or twisted connecting rod, Fig. 9.

NOTE: Thrust faces must be free of any burrs or

nicks or connecting rod will not lay flat on

surface plate.

a. With connecting rod on a surface plate, any

distortion will be evident by a rocking motion.

b. If a 0.05 mm (0.002”) feeler gauge can be

inserted at piston pin end of connecting rod the

rod must be replaced.

Fig. 9 –Checking Connecting Rod

ASSEMBLE PISTON AND

CONNECTING ROD

Assemble piston to connecting rod, Fig. 10.

NOTE: Arrow on piston and ID mark on rod must

face same side.

1. Lubricate piston pin with engine oil before assembly.

a. Be sure retainers are seated properly in

piston.

Fig. 10 – Assembling Piston And Rod

ID

MARK