11

24

STARTER SYSTEM

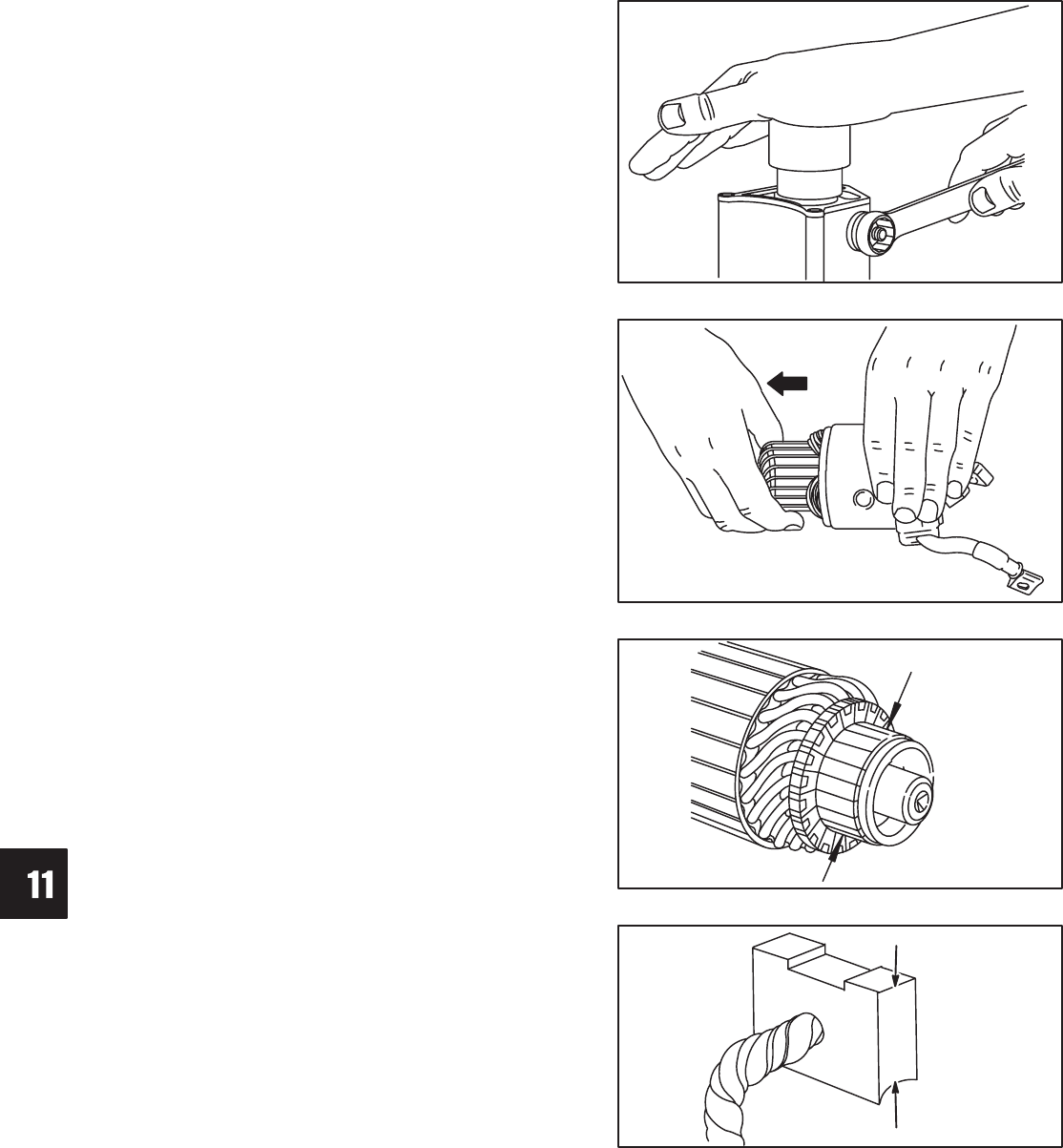

9. Install new plunger and spring.

10. Place bearing driver, Tool #19422 on plunger and

compress plunger to end of travel. Maintain

pressure.

a. Torque nuts to 17 Nm (150 in. lbs.).

Note: This provides proper contact alignment

with plunger and contact plates.

11. Clean contact plates and plunger contacts.

12. Install cover plate with new gasket.

a. Torque screws to 4 Nm (35 in. lbs.).

Fig. 66 – Aligning Contact Plates

DISASSEMBLE STARTER MOTOR

1. Remove starter motor from drive housing.

2. Remove screws and end cap.

3. Remove armature from motor housing, Fig. 67.

If armature drive splines or armature bearings are

damaged or worn, replace armature.

Fig. 67 – Disassemble Starter Motor

Inspect Armature Commutator

The armature commutator may be cleaned with fine

sandpaper. DO NOT use emery cloth. Commutator

may be machined to no less than 29.0 mm (1.142”),

Fig. 68.

NOTE: Minimum depth of slots between

commutator bars after machining is 0.2

mm (.008”).

The armature should be checked for shorts with a

growler.

Fig. 68 – Commutator Specifications

29.0 mm

Inspect Brushes

Minimum brush dimension is shown below Fig. 69.

1.0 KW Starter: 9 mm (.350”).

1.2 KW Starter: 10 mm (.400”).

If brushes are worn less than specification, replace as

follows.

1.0 KW Starter: Replace brush retainer and brushes

on starter housing.

1.2 KW Starter: Starter housing and brush retainer

must be replaced as an assembly.

Fig. 69 – Minimum Brush Dimension

1.2 KW: 10 mm

1.0 KW: 9 mm