2

5

CYLINDER HEAD AND VALVES

INSPECT AND REPAIR

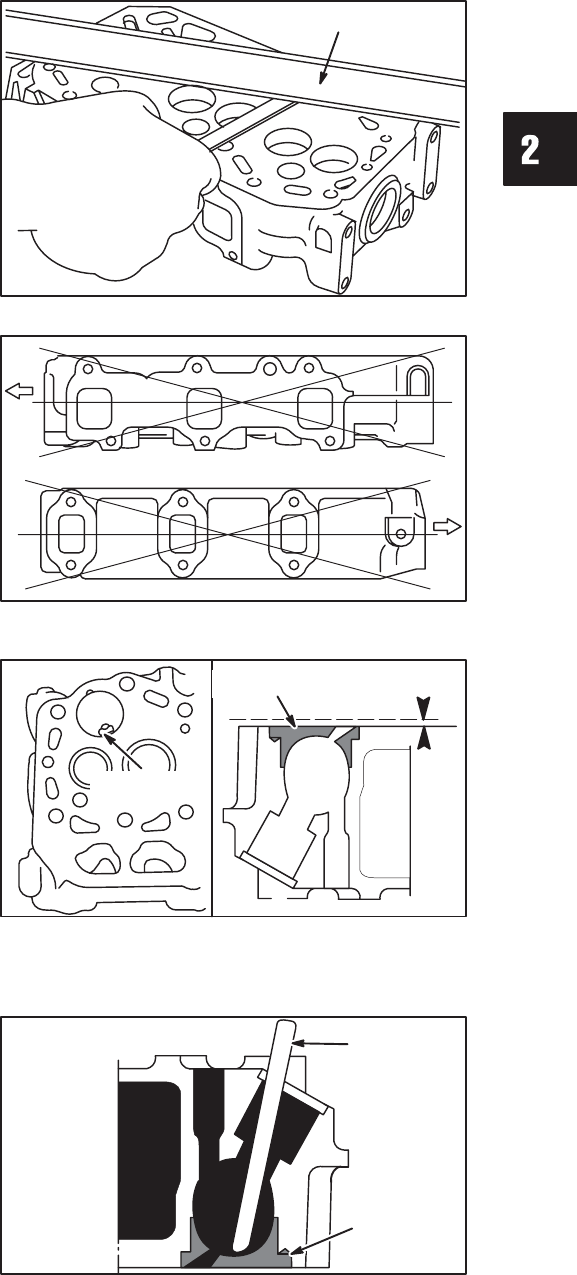

1. Check cylinder head mounting surfaces, Fig. 12

and Fig. 13.

Be sure all gasket material is removed from surfaces

before checking. Use a gasket scraper if necessary.

a. Inspect cylinder head for cracks or damage.

b. Use a straight edge and check cylinder head

lower surface for distortion.

Fig. 12 – Check Cylinder Head For Distortion

STRAIGHT

EDGE

Fig. 13:

c. Check intake and exhaust manifold mounting

surfaces.

If mounting surfaces are distorted more than 0.1 mm

(0.004 in.), the cylinder head must be replaced.

It is not recommended that cylinder head

mounting surfaces be resurfaced.

NOTE: Intake manifold and exhaust manifold

may be checked in the same manner. Use

same specifications as cylinder head.

Fig. 13 – Check Cylinder Head For Distortion

CHECK COMBUSTION CHAMBER

Engine Model 522000: combustion chambers are

not replaceable.

Engine Models 432000 and 582000 with date code

after 990111007: combustion chambers are not

replaceable.

NOTE: Only Engine Models 432000 and 582000

with date code before 981225006 have

replaceable combustion chambers.

1. Check combustion chamber, Fig. 14.

a. Use a straight edge and feeler gauge.

If combustion chamber protrudes more than 0.05 mm

(.002 in.) above surface of cylinder head, it must be

replaced.

Fig. 14 – Check Combustion Chamber

COMBUSTION

CHAMBER

COMBUSTION

CHAMBER

2. Remove combustion chamber, Fig. 15.

Insert a 10 mm brass rod through injector nozzle hole

and drive out combustion chamber.

NOTE: Do not damage threads in injector hole.

Fig. 15 – Remove Combustion Chamber

BRASS ROD

COMBUSTION

CHAMBER