EPRI Proprietary Licensed Material

3-1

3

RELIABILITY, AVAILABILITY AND MAINTAINABILITY

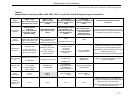

Data Analysis: Rolls-Royce Aero-derivative Engines

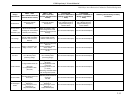

This chapter provides statistical evaluation of the Reliability, Availability, and Maintainability

(RAM) performance of the Rolls-Royce Avon, RB211, and Trent machines in power generation

applications. The fleet is represented by units that report to the Operational Reliability Analysis

Program (ORAP) managed by Strategic Power Systems (SPS). RAM data is reported to ORAP

on a voluntary basis and therefore not all units in a particular fleet are represented. To the extent

that the data is based on a substantial number of the fleet units in a particular category, the results

are representative statistical sampling of that fleet. See Appendices for details about ORAP and

RAM statistics.

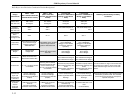

Simple cycle plant statistics are provided in this report because the focus is on the combustion

turbine. The impact of the combustion turbine and its interaction with the operation and

maintenance of the plant is considered the prime issue. Other studies examine the balance of

plant RAM for combined cycles, including the HRSG and steam turbines.

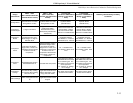

For most models, the majority of the units reporting in the ORAP database are baseload electric

or cogenerators, although the smaller capacity models also have a substantial number of units in

simple cycle mode for peaking duty. The units currently performing cycling duty formerly were

baseloaded units and have recently transitioned to cycling duty. At a site with a single unit the

tendency of the cycling unit is to shutdown for the weekend. At sites with multiple units the

tendency of the cycling units is shutdown on a rotating schedule. Some of the units run for

longer fired hours per start, then shutdown on the third night and restart in the morning to

minimize the total number of on-off cycles.

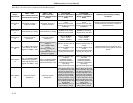

The maintenance philosophy implemented by the OEMs and Users has a direct impact on RAM

and is the leading cause of a plant’s unavailability. The demand and use of a combustion turbine

greatly influences these decisions but unavailability is a User/OEM controlled parameter of when

and how scheduled and unscheduled maintenance is performed. For instance, plants that are

simple cycle peakers may have less incentive to minimize the time required to perform scheduled

maintenance, and therefore have lower availability than baseload units of the same model. For

peakers, reliability and availability are most critical during seasons in which electricity prices are

at a premium.

This report contains a summary of RAM statistics available at the time of publication. More

detailed statistics, including future annual updates, are available to current project 80.002 funders

via electronic download from www.epri.com. Login is required. Proceed to Program 80 in the