EPRI Proprietary Licensed Material

Rolls-Royce Aero-Derivative Combustion Turbine Background

2-10

The 17 stage gas generator provides a compression ratio of 8.8:1 and is driven by a 3 stage

turbine. The 2 stage power turbine drives a 4-pole generator at 1500-1800 rpm, similar to the

RB211.

Although some new units are sold each year, the product line appears to be phasing out for

electrical generation applications. Rolls-Royce provides continuing support for the relatively

large existing fleet. Furthermore, several upgrades have been implemented: the swirler burner

for improved handling of liquids in otherwise gaseous fuel (similar to the upgraded diffusion

burner for the RB211), and improved components for increased power and efficiency. Even

though a DLE combustor was previously announced for the Avon, that work is apparently not

going forward. Although standardized skid-mount packages are being developed for the RB211

and Trent, the effort for a highly-engineered Avon package is not anticipated.

Unlike the maintenance schedule for the RB211 and Trent engines, the Avon is refurbished at

roughly 30,000 and 60,000 hours, while undergoing a comprehensive overhaul at 90,000-

100,000 hours. The standard turnaround time is 40 days.

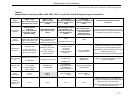

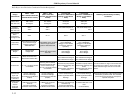

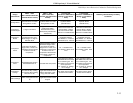

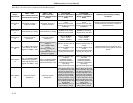

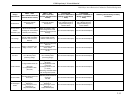

Pedigree Matrix for the RB211 and Trent 60 Engines

This section provides a review of the Pedigree Matrix developed for the Rolls-Royce RB211 and

Trent industrial combustion turbine product line currently relevant for new electrical generation

projects. The Pedigree Matrix is structured to show the distinguishing characteristics of the

selected models, and the significant or major design changes from each model.

The Pedigree Matrix for the Rolls-Royce RB211-6562, RB211-6761 (Uprate), and the Trent 60

current production industrial units is provided in the following table. Items with gray

background highlight areas of significant design changes compared with previous designs from

the manufacturer.