EPRI Proprietary Licensed Material

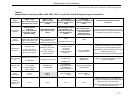

Rolls-Royce Aero-Derivative Combustion Turbine Background

2-4

RT 56 – (Cooper Bessemer) 56” Diameter, two stage, Reaction Turbine.

For the –22, -24A and –24C engines

RT 62 - (again Coopers) 62” Diameter, two stage, Reaction Turbine.

For the –24G and –24G DLE engines

RT 61 - (based on the Trent 800 aero engine) 61“ Diameter, three stage, Reactive Turbine

For the –24GT or uprated engine

RB 211 Maintenance Approach.

The time line for RB 211 maintenance, based on over 25 years of operating experience, is as

follows:

• 2,000 hour Inspection and Compressor soak wash

• 8,000 hour Inspection and borescope inspection

• 25,000 hour Mid Life Inspection & 04 Module Overhaul

• 50,000 hour Full Overhaul of the engine

(Inspection/overhaul details and workscope are described in the Appendix).

Both the 2,000 and 8,000 hour Inspections are carried out with the engine remaining in place.

The 2,000 inspection and soak wash can be accomplished in 4 to 6 hours, whereas the 8,000 hour

inspection with the borescope will need 8 to 10 hours of downtime. The standard turnaround

time for the RB211 gas generator is roughly 40-50 days.

For the Mid Life Inspection, the engine has to be removed from the berth but may be overhauled

at the site or depot. If spare 04 Module and IP Compressor Stator assemblies or access to ‘pool’

units is available, the work can be done on site. Otherwise, the engine is dispatched to the

Vendor’s overhaul shop to carryout this operation.

The Modular design of this engine allows for the swap of any Module once the engine is ‘bulk

stripped’ to its individual Modules. In the case of the 25,000 hour Mid Life, the 04 Module has

to be changed out. With the Vendors repair crew of two / three men, along with their tooling,

this task can be accomplished in three to four days, depending on client’s downtime window.

Two cranes (3 Tonne & 5 Tonne) with a lift height of 14 meters is a minimum requirement.

Historically, there are two areas in the RB 211 that have been life-limiting features. First, the

rubber dampening used in the inner shrouds of the I.P. Compressor Stage 5, 6 Stator

assemblies and the Stage 7 Stator or Outlet Guide Vane assembly degrades. This allows the

vanes to ‘flutter’ and leads to high cycle fatigue. Thus far, these assemblies have to be inspected

at 25,000 hours. Secondly, the ‘Z’ notch of the H.P. Turbine Blade outer shrouds suffers

from heat erosion and need to be repaired at this juncture. Failing that, the erosion will progress

to a point where the blades are beyond repair limits.