EPRI Proprietary Licensed Material

Rolls-Royce Aero-Derivative Combustion Turbine Background

2-8

controls water usage to meet emission levels for changes in power demand and ambient

conditions.

The 8-stage intermediate pressure compressor (IPC) and the 6-stage high-pressure compressor

(HPC) are identical to the Aero Trent 800. The HPT and IPT are also single stages and identical

to the Aero 800 Trent. The low-pressure turbine LPT incorporates five stages, of which the first

three stages are identical to the Aero 800 Trent. The last two stages have longer blades because

the low-pressure shaft system is a direct drive system rotating at lower speed than the aero and

the expansion ratio is higher. This increase in expansion ratio is due to the need to extract all the

available energy for power production in the industrial turbine while the aero version retains

some of this kinetic energy to provide thrust.

Like GE’s LM6000, the low-pressure spool rotates at 3600/3000 rpm and is directly coupled to

the generator. No reduction gearbox is required. For 50-Hertz operation, the stagger angle on

the low-pressure compressor blades are changed slightly and the LPC rotates at 3000 rpm. The

industrial Trent is unique in that it is the largest aero-derivative combustion turbine in the world

at 51.2 MW and incorporates the three-shaft arrangement in both the compressor and turbine

sections. The industrial Trent is a hot end drive.

The three-shaft arrangement provides for better stage matching and performance since each

spool is optimized and allows for more efficient operation than an equivalent 2-spool turbine.

This design results in fewer stages, fewer airflow regulating provisions such as variable stators

and bleeds, a shorter turbine, and a high degree of modularity with its attendant benefits during

maintenance.

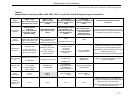

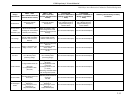

Figure 2-2

Industrial Trent