EPR Proprietary I Licensed Material

Rolls-Royce Aero-Derivative Combustion Turbine Background

2-5

Once the engine is removed from the berth, it can be placed on its transportation stand. At this

point the I.P. Turbine assembly can be uncoupled from its curvic coupling and removed. Then,

by use of the two cranes, the engine can be lifted into the vertical position and be placed nose

down on the lifting fixture. This allows for the removal of the 05 and the 04 Modules.

At this point the 01, 02 and 03 Modules are lifted and turned such that the assembly is now

resting on the 03 Module casing. This allows for the removal of the 01 and 02 Modules. Once

the 02 Module is removed the half casings can then be split, allowing access to the Stage 5 and 6

Stator assemblies for replacement.

The Stage 7 or OGV Ring assembly is the front part of the 03 module and can be replaced with

the spare assembly or ‘pool’ unit.

Rebuilding the engine is basically the reverse of the above procedure.

The 04 Module, along with the I.P. Stage 5,6 and 7 Stators, are then taken back to the overhaul

shop for full refurbishment to the latest Mod standard, to be placed back in the ‘pool’ or returned

to the Customer, if they were his spare assemblies.

One thing that should be emphasized here is that this experience is based on base load operation,

using gas fuel. Deviations from this scenario i.e. prolonged running with the bleed valves open,

will alter the inspection criteria. Other than these inspections clean fuel and clean air are a

must, to help prolong the life of the engine.

Turnaround Time and Costs

• As mentioned above, a Mid Life can be accomplished in the field with two men in 3 to 4

days.

• The 04 module will take approximately 40 days to fully recondition in the overhaul shop. In

the case of the IP Stage 5, 6 and 7 Stator assemblies, it will take 21 days to accomplish their

repair.

• Average cost of a Mid Life on the above components has been running in the region of

$ 345,000 to 375,000 US.

• For a full engine overhaul, the turntime is averaging 95 days and the costs are in the region of

$850,000 US.

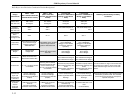

Parts Life Upgrades

As discussed in the section - Maintenance Approach, the parts life issue was detailed. In the case

of the I.P. Compressor Stator assemblies, here are the latest Modifications these parts should be

refurbished to.