E-Maxx

•

23

Gearing Compatibility Chart:

The chart below shows a full range

of gear combinations. This does NOT

imply that these gear combinations

should be used. Over-gearing

(bigger pinions, smaller spurs) can

overheat and damage the motor

and/or speed control.

Motors and Gearing

The Titan

™

550 Motors on your E-Maxx have been carefully designed

to match the needs of the E-Maxx. The Titans are made to run

efciently at high voltage to provide more torque and longer run

times. We do not recommend converting the E-Maxx to a typical

low voltage setup using traditional 540 size motors. While these

components will physically t into the E-Maxx, the system will not run

as efciently, losing power in the form of motor and battery heating.

The result will be shorter run times, high current draw, and extreme

battery and motor temperatures. If you are considering replacement

motors, look for 550 motors capable of 12 or more volts.

The E-Maxx is equipped from the factory with a 68-tooth spur gear

and 19-tooth pinion gears. E-Maxx has a large range of gearing

making it suitable for many different types of applications and

environments. If you want more acceleration and less top speed, use

a smaller pinion gear (fewer teeth, higher numerical ratio). The overall

reduction is the number of turns the motor makes for one revolution

of the tire. Higher numerical ratios provide more torque, lower

numerical ratios provide more top speed. With the Titan motors,

do not use a pinion gear larger than 20-tooth with the stock 68-

tooth spur gear with 6-cell battery packs or a pinion gear larger

than 19-tooth with the stock 68-tooth spur gear when using 7-cell

battery packs. Use the following formula to calculate the overall ratio

for combinations not listed on the gear chart:

Going Brushless

Brushless motors provide increased power output and greater

efciency. The E-Maxx is designed with extra transmission and

driveline strength to make it capable of handling extreme brushless

power. One or two brushless motors may be used. A specially

designed motor plate (part # 3997X) and gear cover (part # 3977X)

are available for optimized, single-motor installations. If you plan

to run LiPo battery packs to power a LiPo-compatible brushless

system, optional battery hold downs (part # 3927X) are available to

accommodate larger, high capacity 2S and 3S LiPo battery packs.

For the ultimate in extreme brushless speed and acceleration, install

twin Velineon power systems (part number 3350). Two Velineon

brushless motors powered by two Velineon VXL-3s speed controls in

tandem results in amazing power output. Visit www.Traxxas.com for

more details about power upgrades.

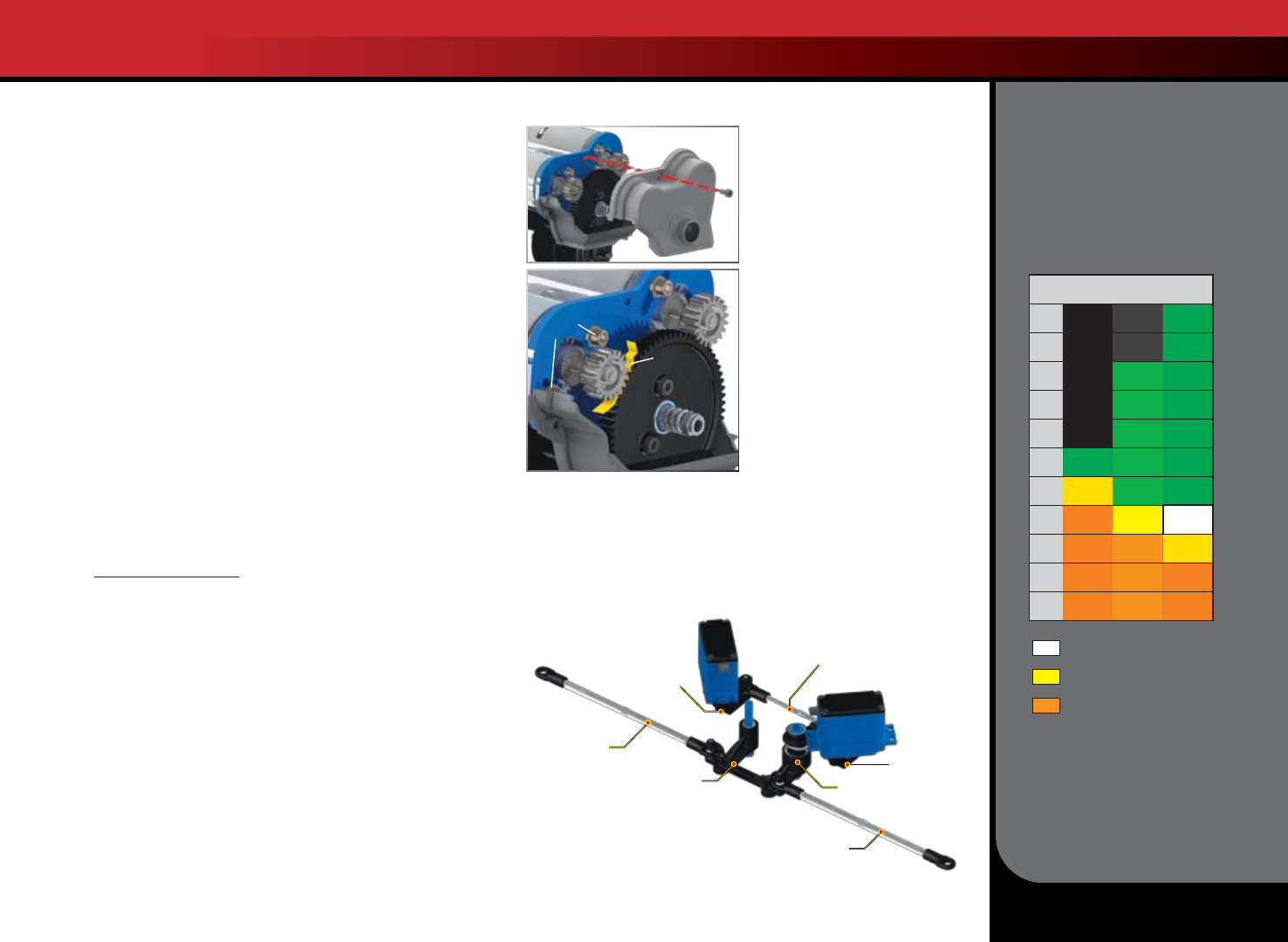

Adjusting Gear Mesh

Incorrect gear mesh is the most

common cause of stripped spur

gears. Gear mesh should be

checked and adjusted anytime

a gear is replaced. Access the

gears by removing the single

screw on the top gear cover.

To set the gear mesh, cut a

narrow strip of notebook paper

and run it into the gear mesh.

Loosen the motor screws and

slide a motor and pinion gear

into the spur gear. Retighten

the motor screws and then

remove the strip of paper.

Repeat with the other motor.

You should be able to run a

fresh strip of paper through the

gears without binding them.

Dual Steering System

Your new E-Maxx uses dual-servo steering and a single heavy-duty

servo saver for powerful, responsive steering. To prevent damage

to the steering servos, it is important to make sure that the servos

are “at rest” when the steering is at neutral. If one servo is out of

adjustment, then both servos will work against each other, ghting

to nd center.

# Spur Gear Teeth

x 5.22 = Final Gear Ratio

# Pinion Gear Teeth

Tuning Adjustments

Motor

Screws

Strip of

Paper

Stock factory gearing

Not for 14-cell

battery running

Not recommended

Spur Gear

Pinion Gear

62 65 68

12

- - 29.57

13

- - 27.29

14

- 24.23 25.34

15

- 22.61 23.65

16

- 21.20 22.18

17

19.03 19.95 20.87

18

17.97 18.84 19.71

19

- 17.85 18.67

20

- - 17.74

21

- - -

22

- - -

Servo Saver

Center

Drag Link

Servo Horn

Servo Horn

Toe Link

Toe Link

Bellcrank