flO%

SLM/24

VDC

flO%;

0 to 50 SLM/15 VDC

mA

into 1000 ohm

maximum load resistance for 24 VDC supply (500 ohm/l5

VDC supply).

CONTROL RANGE: Calibrated for 10 to 100% of full scale.

INPUT POWER: 0 to 15

kg/cm*)

optimum.

GASES: Most gases (e.g., air, nitrogen, methane, carbon

dioxide, argon, helium, hydrogen); check compatibility with

wetted materials; specify when ordering.

OUTPUT SIGNALS: Linear O-5 VDC into 2000 Ohm minimum

load resistance standard or linear 4-20

kg/cm*)

differential standard; 30 PSI (2 (0.35-3.5

nm3/h).

FMA-1900 SERIES MINIMUM DP REQUIREMENTS: 5-50

PSI

“C (70°F). Other ranges in other units are available (e.g.,

SCFH or

.l

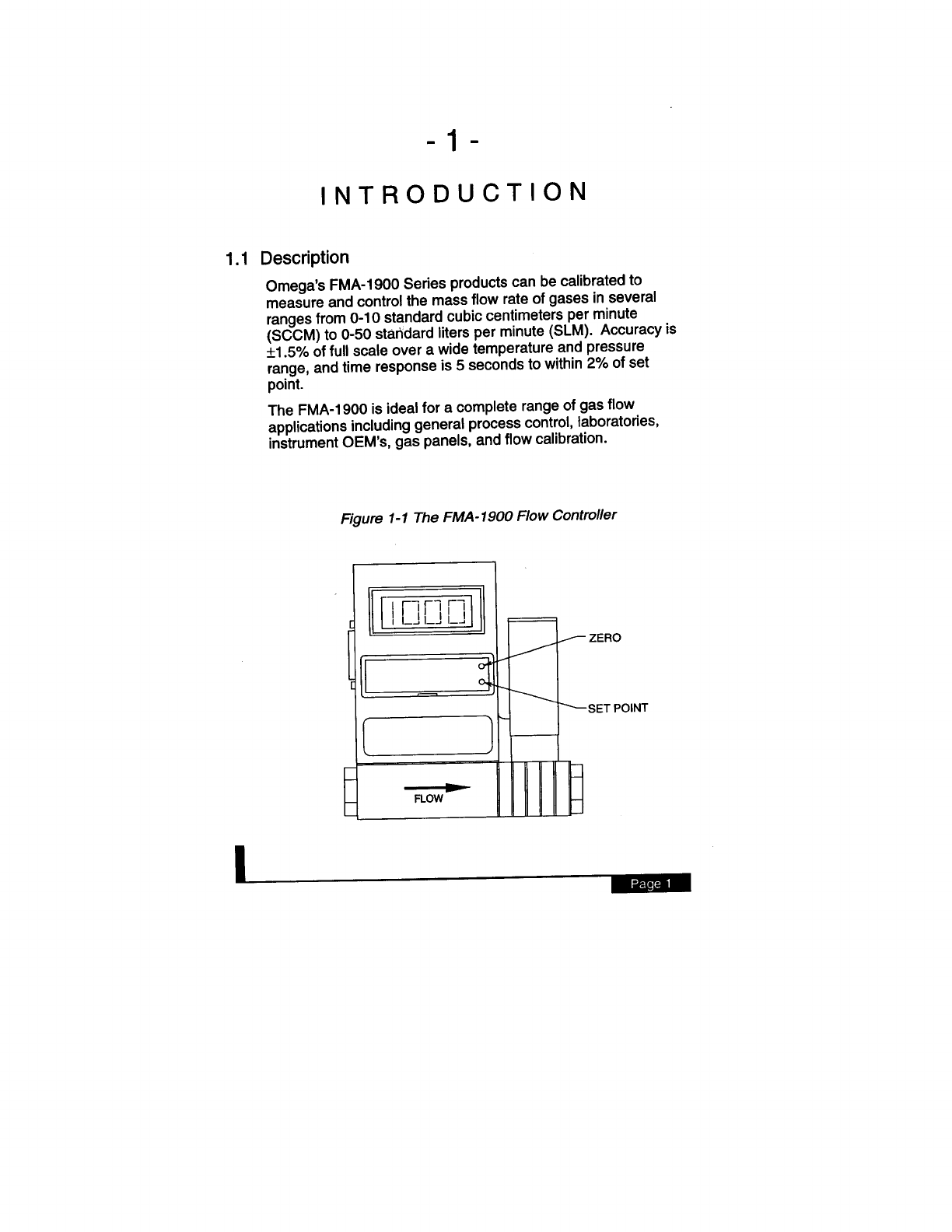

“D”

connector is provided for power input, output signal and set

point control. FMA-1900 is available in several basic configu-

rations with either NPT (female) or compression inlet/outlet

fittings, and with or without the optional power supply.

l&Specifications

FLOW RATES: O-10 SCCM to O-50 SLM; flow ranges speci-

fied are for an equivalent flow of nitrogen at 760 mm Hg and

21

15-pin

mA

output

signals, which are linearly proportional to gas mass flow rate,

are provided for recording, data-logging, or control. A

The versatile FMA-1900 product digitally displays the mass

flow rate directly in engineering units or percent of full scale.

The FMA-1900 is a transducer requiring a regulated 24 VDC

external power source. The O-5 VDC and 4-20