6.3

Section 6

Lubrication System

6

3. Before removing the oil filter, clean the

surrounding area to keep dirt and debris out of the

engine. Remove the old filter and wipe/clean the

surface where the filter mounts.

4. Reinstall the drain plug. Make sure it is tightened

to 13.6 N·m (10 ft. lb.).

5. Place a new oil filter in a shallow pan with the

open end up. Pour new oil, of the proper type, in

through the threaded center hole. Stop pouring

when the oil reaches the bottom of the threads.

Allow a minute or two for the oil to be absorbed by

the filter material.

6. Put a drop of oil on your fingertip and wipe it on

the rubber gasket.

7. Install the new oil filter to the filter adapter. Turn

the oil filter clockwise until the rubber gasket

contacts the surface, then tighten the filter an

additional 2/3-1 turn.

8. Fill the crankcase with new oil of the proper type,

to the ‘‘FULL’’ mark on the dipstick. Refer to ‘‘Oil

Type’’ and ‘‘Check Oil Level’’ on pages 6.1 and

6.2. Always check the level with the dipstick

before adding more oil.

9. Reinstall the oil fill cap/dipstick and tighten

securely by turning to the right.

NOTE: To prevent extensive engine wear or

damage, always maintain the proper oil

level in the crankcase. Never operate the

engine with the oil level below the ‘‘ADD’’

mark or above the ‘‘FULL’’ mark on the

dipstick.

Angle of Operation

This engine will operate continuously at angles up to

20º. Check oil level to assure crankcase oil level is at

the ‘‘FULL’’ mark on the dipstick.

Refer to the operating instructions of the equipment

this engine powers. Because of equipment design or

application, there may be more stringent restrictions

regarding the angle of operation.

NOTE: Do not operate this engine continuously at

angles exceeding 20º in any direction. Engine

damage could result from insufficient

lubrication.

Oil Sentry

™

General

Some engines are equipped with an optional Oil

Sentry

™

oil pressure switch monitor. If the oil pressure

decreases below an acceptable level, the Oil Sentry

™

will either shut off the engine or activate a warning

signal, depending on the application.

The pressure switch is designed to break contact as

the oil pressure increases, and make contact as the oil

pressure decreases. At oil pressure above

approximately 3.0/5.0 psig, the switch contacts open.

Below this pressure, the switch contacts close.

On stationary or unattended applications (pumps,

generators, etc.), the pressure switch can be used to

ground the ignition module to stop the engine.

On vehicular applications (lawn tractors, mowers, etc.)

the pressure switch can only be used to activate a

warning light or signal.

NOTE: Make sure the oil level is checked BEFORE

EACH USE and is maintained up to the

‘‘FULL’’ mark on the dipstick. This includes

engines equipped with Oil Sentry

™

.

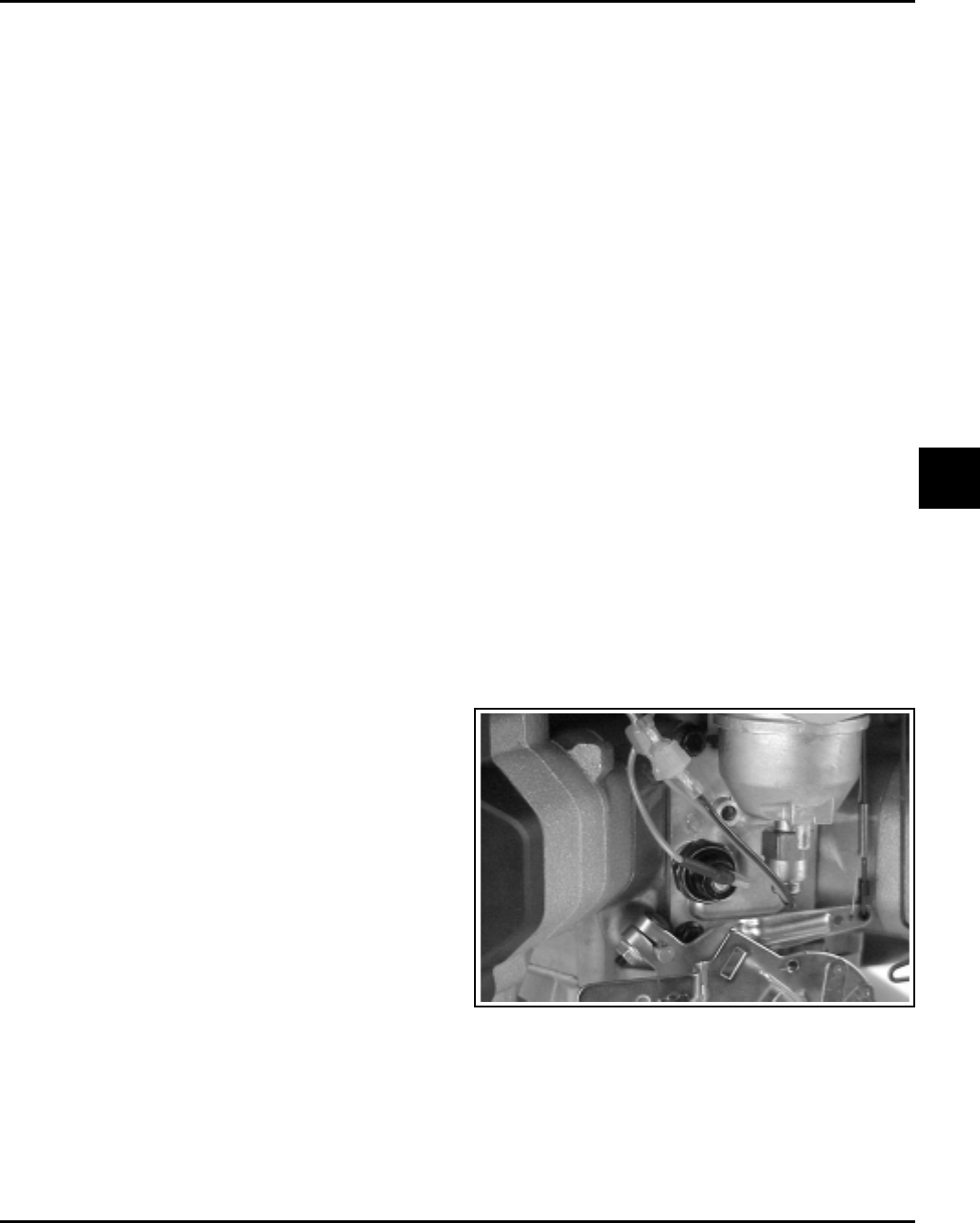

Installation

The Oil Sentry

™

pressure switch is installed on the

breather cover. See Figure 6-5.

Figure 6-5. Oil Sentry

™

Location.

On engines not equipped with Oil Sentry

™

the

installation hole is sealed with a 1/8-27 N.P.T.F.

pipe plug.