bühler

1500 Bale Carrier

16

LUBRICATION

CAUTION

Place all controls in neutral, stop engine, set parking brake

and remove ignition key before inspecting, servicing, adjusting or repairing the 1500

Bale Carrier.

CAUTION

Ensure the 1500 Bale Carrier tires and hitch are securely

blocked. Otherwise, verify the 1500 Bale Carrier is properly coupled to the drawbar on a

tractor with a minimum mass of 12480 LB (5660 kg).

Pivot Points

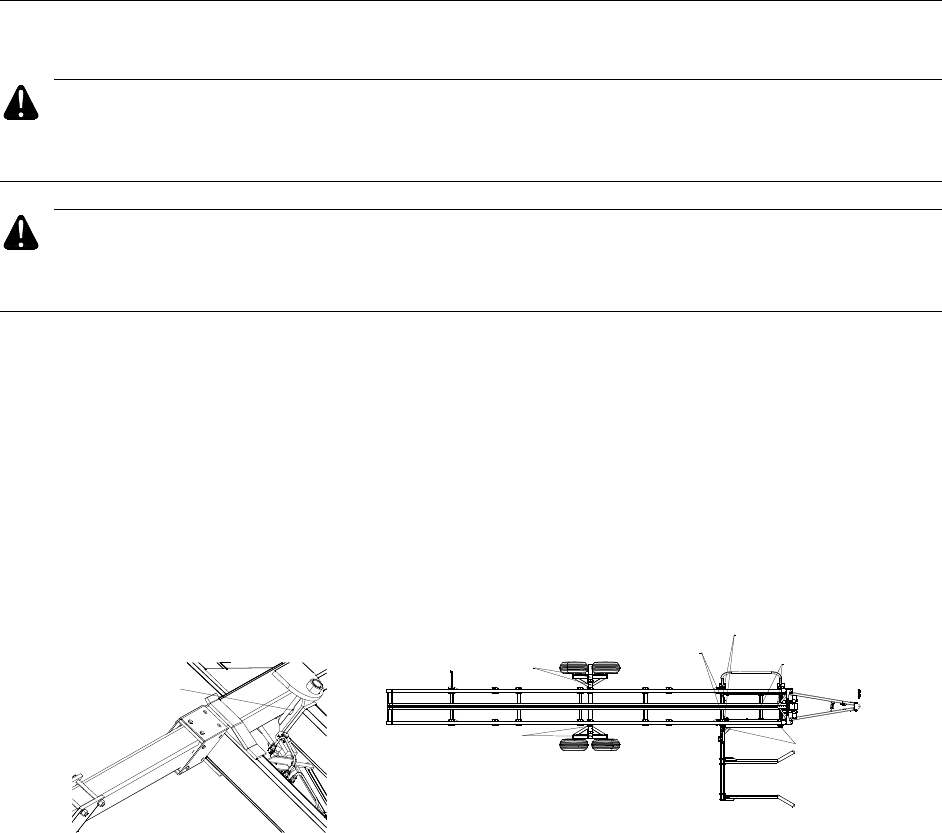

Lubricate 1500 Bale Carrier bushings and pivots every eight hours of average

operation with high-grade grease at all fitting locations. Select grease based on

the expected outside temperature range. Lithium, Molybdenum and synthetic

greases are preferred. Use the tractor hour meter as a guide. Increase lubrication

intervals for extreme use or adverse conditions. Each pivot should be lubricated

until grease is visible at pin. The fixed arm carrier has 12 lubrication points and

the RPU carrier has 13 points. Refer to the illustrations below for locations.

RPU PIVOT LEFT

AND RIGHT SIDES

HITCH BEAM

AXLE BEARING

AXLE BEARING

HYDRAULIC CYLINDER ENDS

HYDRAULIC CYLINDER

ENDS

BUSHINGS

RPU LUBRICATION LUBRICATION ILLUSTRATION

ILLUSTRATION

Roller Chain

Manually brush SAE lubricant while chain is stationary.

Lubricate the chain every time bolt torque maintenance is performed.

Carrier Beams

Apply a graphite coating such as Slip Plate

TM

to the carrier beams as required to

ensure a smooth push back operation.

Follow application instructions as provided by the coating manufacturer.

At the end of the season apply a coating to prevent rust on the carrier beams.