April 1, 2006 14 Lit. No. B64090, Rev. 00

MOLDBOARD & A-FRAME ASSEMBLY

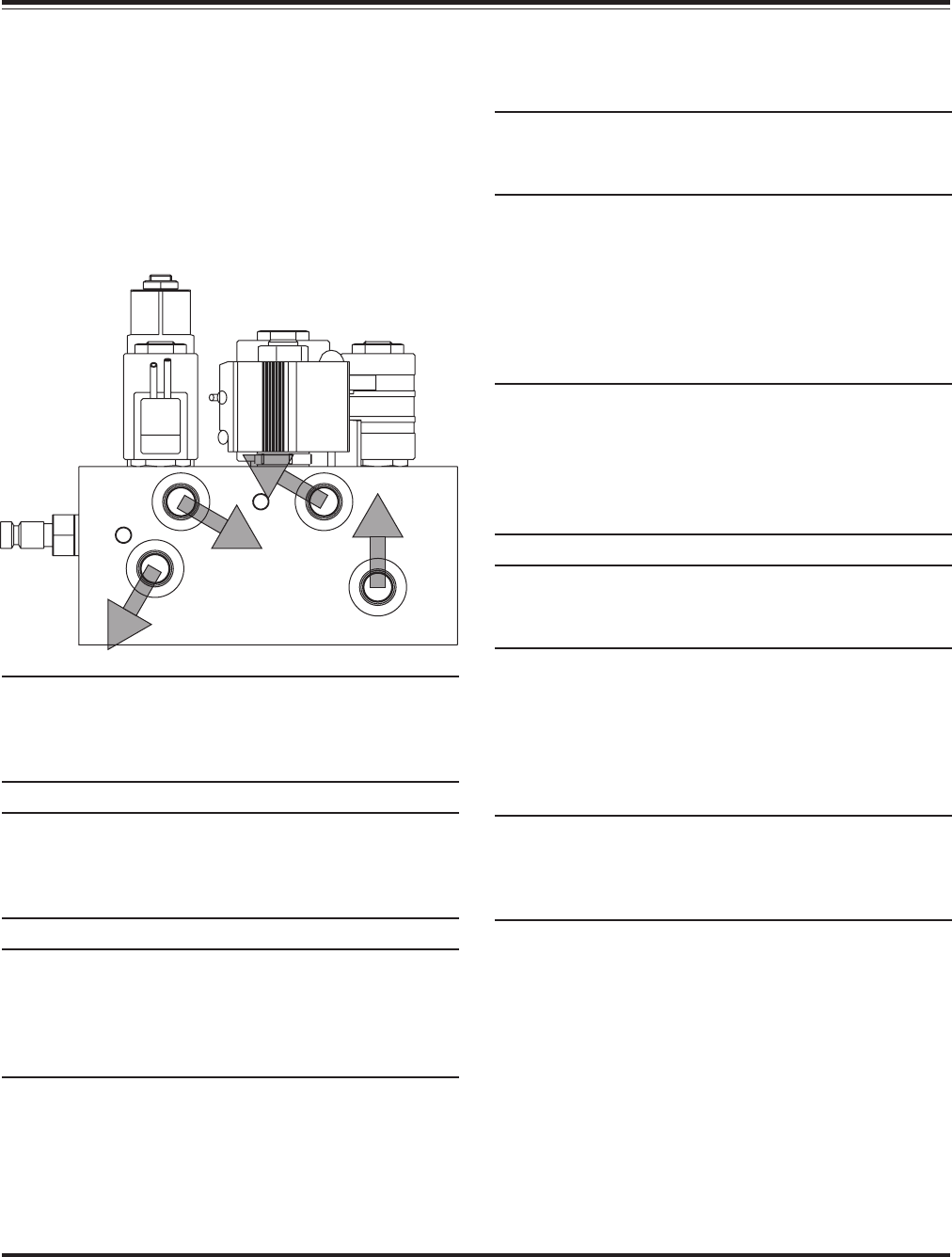

7. Assemble the manifold. The manifold, pump and

coil harness have been connected at the factory;

however, the manifold contains several

components that you will need to install prior to

securing the assembly to the A-frame. Each of the

hose ports on the manifold is covered with stretch

wrap. Remove the wrap and install the appropriate

fitting in its respective port. Tighten fittings and

hoses per torque chart.

NOTE: The arrows shown on the manifold

illustration indicate the direction the 90° adapters

should be positioned to receive the hydraulic

hoses.

NOTE: DO NOT let any foreign objects enter into

the open ports. The valves can become

contaminated and greatly hinder the plow’s

performance. Torque to proper specifications.

NOTE: All ports are identified by a stamped

number on the manifold. The numbers also

identify the hydraulic functions, which can be

referenced on the label under the hydraulic pump

and manifold cover.

8. Align the mount holes in the pump with the holes

in the hinged bracket, located on the A-frame.

NOTE: Before mounting the pump, angle the

hinged bracket as needed and tighten the bracket

hardware to lock it in place.

Secure with 3/8"-16 x 3/4" hex head cap screw and

3/8" flat washer through the top mount hole in the

bracket and into the pump. Insert 3/8"-16 x 1-3/4"

threaded stud with 3/8"-16 locknut through the

bottom mount hole in the bracket and into the pump.

The threaded stud should bottom out in the pump.

NOTE: When installing the manifold between the

mount brackets on the A-frame, hold the manifold

at the sides of the block. Never handle the

manifold by coils. Doing so can cause a solenoid

cartridge to bend, causing the cartridge to stick

when activated.

NOTE: A medium strength thread-locking

compound should be used on both of the pump

mount fasteners.

9. Connect the hydraulic hoses to their respective

adapters on the manifold. Hose P/N B60091

Ports #1 & #2, Hose P/N B60273 Port #3 and

Hose P/N B60274 Port #4. Tighten hoses per

torque chart.

NOTE: Both lift cylinder hoses should be routed

through the triangular openings in the A-frame.

Position these hoses over the A-frame angle and to

their respective manifold ports.

32

1

4