April 1, 2006 12 Lit. No. B64090, Rev. 00

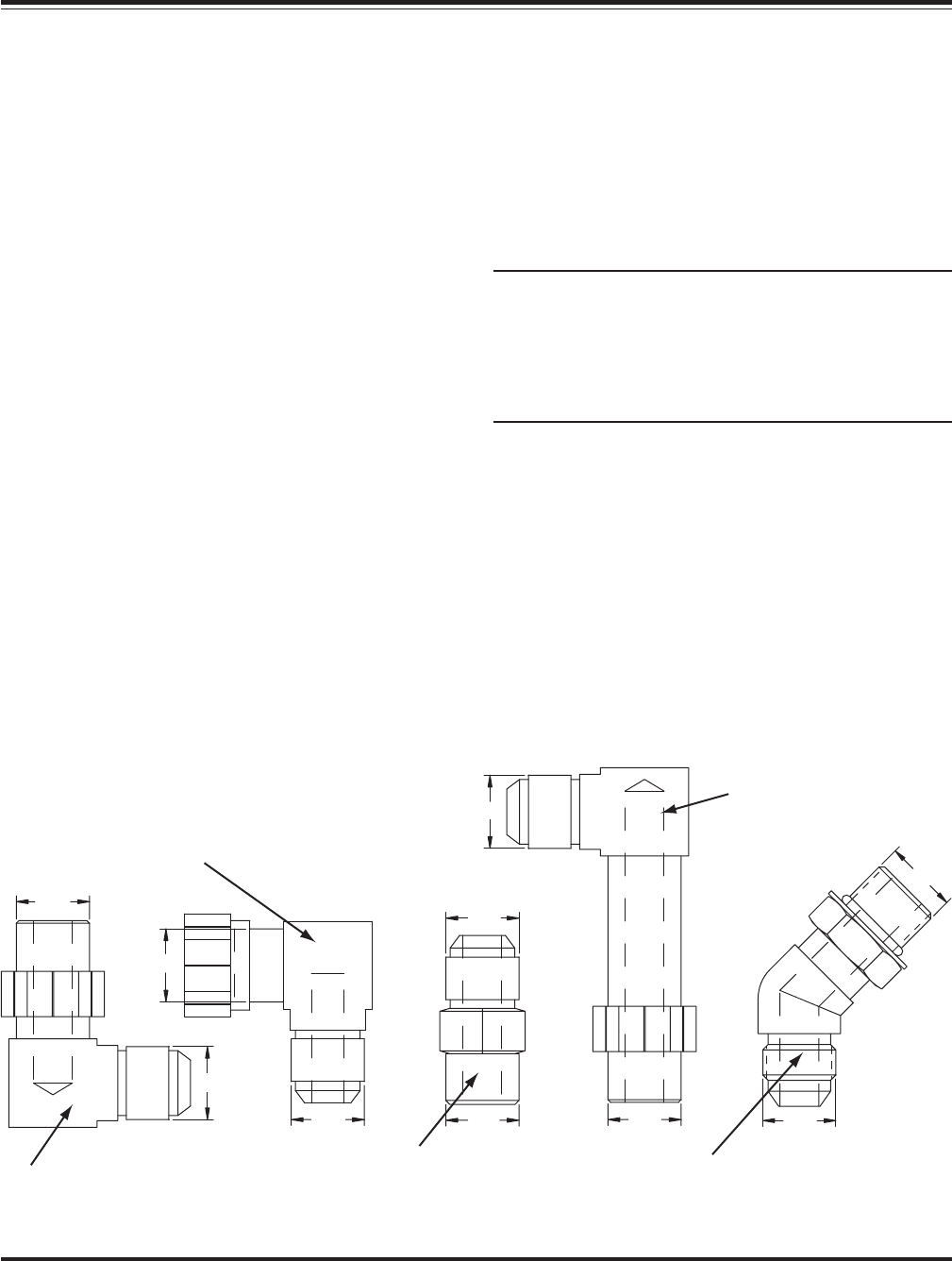

B60007

- Manifold Ports #3 & 4

- Lift Cylinder Rod End

9/16

9/16

B60005

- Manifold Port #1

- Angle Cylinders

9/16

9/16

B60006

- Manifold Ports #3 & 4

9/16

9/16

B60072

- Manifold Port #2

9/16

9/16

B60272

- Lift Cylinder Base End

9/16

9/16

MOLDBOARD & A-FRAME ASSEMBLY

5. Remove the plastic dust caps from the hydraulic

lift cylinder ports. Attach one 9/16"-18 x 9/16"-18

45° adjustable elbow O.R.B. adapter (B60272) to

the driver’s side port (base end) and one

9/16"-18 x 9/16"-18 male O.R.B. connector

adapter (B60007) to the passenger’s side port

(rod end). Once the adapters have been installed

on the cylinder, connect the hydraulic hoses.

Tighten fittings and hoses per torque chart.

NOTE: Position the 45° fitting in the cylinder port

so that the hoses install directly in the center of

the A-frame access holes. A hose installed too

close to the edge of the opening may work itself

free with the operation of the lift cylinder and/or

movement of the plow.

The 45° adapter receives a 3/8" x 17" hydraulic

hose (B60273). Connect the 45° angle on the

hose to the hydraulic adapter on the cylinder. The

male connector adapter receives a 3/8" x 15"

hydraulic hose (B60274). Connect the 45° end of

the hose to the hydraulic adapter on the cylinder.

Both hoses should be routed through the

triangular openings in the A-frame. Tighten fittings

and hoses per torque chart.

3. Position each angle cylinder with the rod end of

the cylinder in the pivot beam and the hydraulic

hose port facing away from the A-frame. Secure

the cylinder to the pivot beam with a 3/4" x 5"

clevis pin (B41051) and a 1/4" x 1-1/2" cotter pin

(B61357). Extend each cylinder rod until the

cylinder base mounting hole aligns with the hole

on the A-frame angle cylinder bracket. Insert

another clevis pin and secure it with a cotter pin.

4. Remove the dust cap from both of the hydraulic

angle cylinder ports and attach one

9/16"-18 x 9/16"-18 90° adjustable elbow O.R.B.

adapter (B60005) to each port. Each adapter

should be angled toward the top of the moldboard.

Connect one 3/8" x 24" hydraulic hose (B60091)

to each angle cylinder adapter. Be careful not to

over tighten the hose connections. Route both

hoses over the TOP of each cylinder. This will

prevent them from hanging or being pinched.

Tighten fittings and hoses per torque chart.