CT06 User Manual ◄ 15

TROUBLESHOOTING

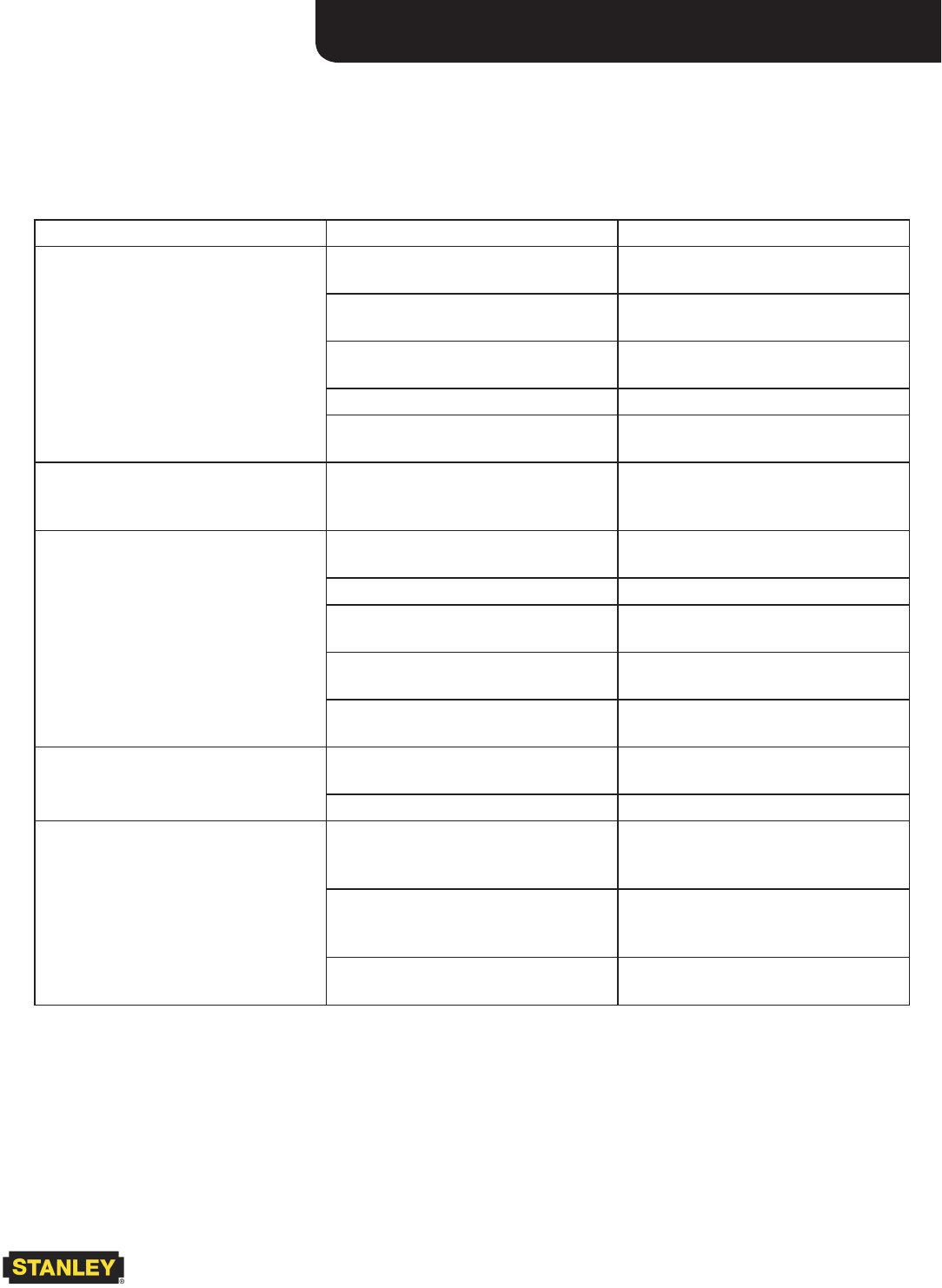

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the crimping tool, always check that the hydraulic power source is supplying

the correct hydraulic ow and pressure to the grinder as listed in the table. Use a owmeter known to be accurate.

Check the ow with the hydraulic oil temperature at least 80 °F/27 °C.

PROBLEM CAUSE SOLUTION

Tool does not operate. Hydraulic hoses not connected

properly.

Make sure hoses are connected

and the couplers are tight.

Hydraulic control valve OFF. Turn the hydraulic system control

valve ON.

Hydraulic system not functioning. Check hydraulic power unit for

correct ow and pressure.

Couplers or hoses blocked. Remove obstruction.

Pressure port check valve is

installed in tool return port.

Install pressure port check valve in

pressure port.

Tool operates in reverse (piston

advances/retracts when trigger is

squeezed).

Hoses connected to wrong ports on

tool.

Connect input (supply) line to IN

port. Connect output (return) line to

OUT port.

Tool under-crimps. Die load less

than 6 tons/5443 kg.

Hydraulic system pressure too low. Check hydraulic power source for

correct ow and pressure.

Relief valve set too low. Increase relief valve pressure.

Dirt or obstruction between dies. Remove obstruction. Clean die

area.

Piston seal worn or damaged. Contact an authorized Stanley

distributor.

Improper die set for wire and

connector.

Install proper die set.

Tool over-crimps. Die load more

than 6 tons/5443 kg.

Hydraulic system pressure too high. Check hydraulic power source for

correct ow and pressure.

Relief valve set too high. Decrease relief valve pressure.

Trigger difcult to operate. Hoses connected to wrong ports on

tool.

Connect input (supply) line to IN

port. Connect output (return) line to

OUT port.

Excessive back-pressure. If back-pressure is greater than

250 psi/17 bar, clear the return line

obstruction or restriction.

Trigger guard bent and binding on

spool in bore.

Repair or replace trigger assembly.