10 ► CT06 User Manual

OPERATION

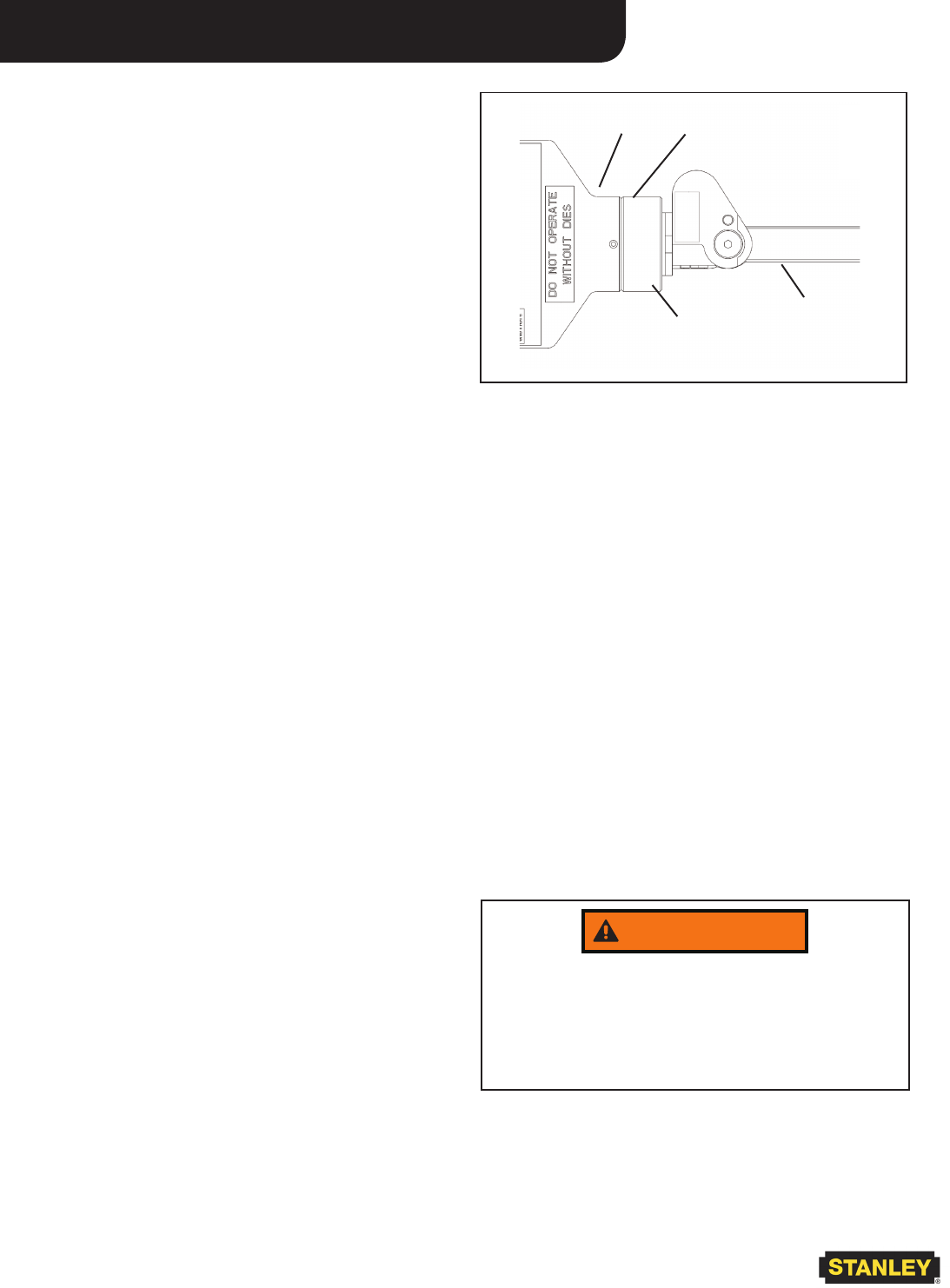

Open-Center (no gap)

Adapter

Cylinder

Trigger

Handle

Top View of Tool

Figure 2. OC/CC Setup

2. Loosen the 2 setscrews on the cylinder.

3. Turn the adapter until it stops:

• Counter clockwise (CCW) to change to closed

center (creates gap)

• Clockwise (CW) to change to open center (clos-

es gap)

4. Tighten the two setscrews.

LATCH NIB REPLACEMENT

The CT06 Hydraulic Crimping Tool has two main com-

ponents in the Anderson compression head:

• The cam yoke assembly forms the base of the com-

pression head. It functions as a movable piston die

to provide the crimping force.

• The latch assembly bridges the cam yoke across

the end of the head. The latch nib in the center of

the assembly is the stationary die.

The following procedure describes how to remove and

replace the latch nibs.

PRE-OPERATION

Careful inspection of the tool and hydraulic system be-

fore startup is important for safe, reliable operation of the

tool.

The following items should be checked daily at the start

and the end of each work shift.

1. Make sure the proper dies are securely in place. Op-

erating the tool without dies can deform the crimping

heads. Refer to Die Installation for instructions.

2. Connect hoses. Wipe all hose couplers with a clean,

lint-free cloth before making connections. Dirty cou-

plers can contaminate the hydraulic lines and pre-

vent a good seal at the connection.

3. Check all fasteners for tightness.

4. Check the equipment for oil leaks. If leaks are ob-

served, do not use the tool; have the equipment ser-

viced before use.

5. Check the tool and hydraulic system for proper op-

eration and performance.

6. If the equipment does not appear to operate prop-

erly, have it serviced before use.

7. Periodically verify the crimping force of the tool. Re-

fer to Die Load Verication.

SETUP AND TEST

Verify the crimping force before operating the tool.

OPEN CENTER/CLOSED CENTER

SETUP

The CT06 Hydraulic Crimping Tool can be congured

for either open-center or closed-center operation. The

current setting is easily determined by looking at the gap

between the adapter and the cylinder:

TO CHANGE THE CURRENT SETTING:

1. Remove the hydraulic hose coupling from the return

port on the tool, if one is installed. When making

the change from CC to OC, hydraulic uid may be

trapped in the tool, preventing complete movement

of the adapter. Remove the return coupling to allow

the hydraulic uid to escape.

WARNING

Installing dies in the tools with the hydraulic hoses

connected can cause severe personal injury or

equipment damage.

To prevent accidental start-up, always disconnect the

hoses before installing dies.