55

55

5

C

83

S4359146

CAUTION

To avoid nitrogen entering

the refrigerant system in a

liquid state, do not use the

nitrogen cylinder up side

down. Use the cylinder in a

vertical standing position.

(Refer to the previous page.)

(4) Do a leak test of all joints of the tubing (both

indoor and outdoor) and both wide and narrow

service valves. Bubbles indicate a leak. Wipe off

the soap with a clean cloth after the leak tests.

(5) After the system is found to be free of leaks,

relieve the nitrogen pressure by loosening the

charge hose connector at the nitrogen cylinder.

When the system pressure is reduced to normal,

disconnect the hose from the cylinder.

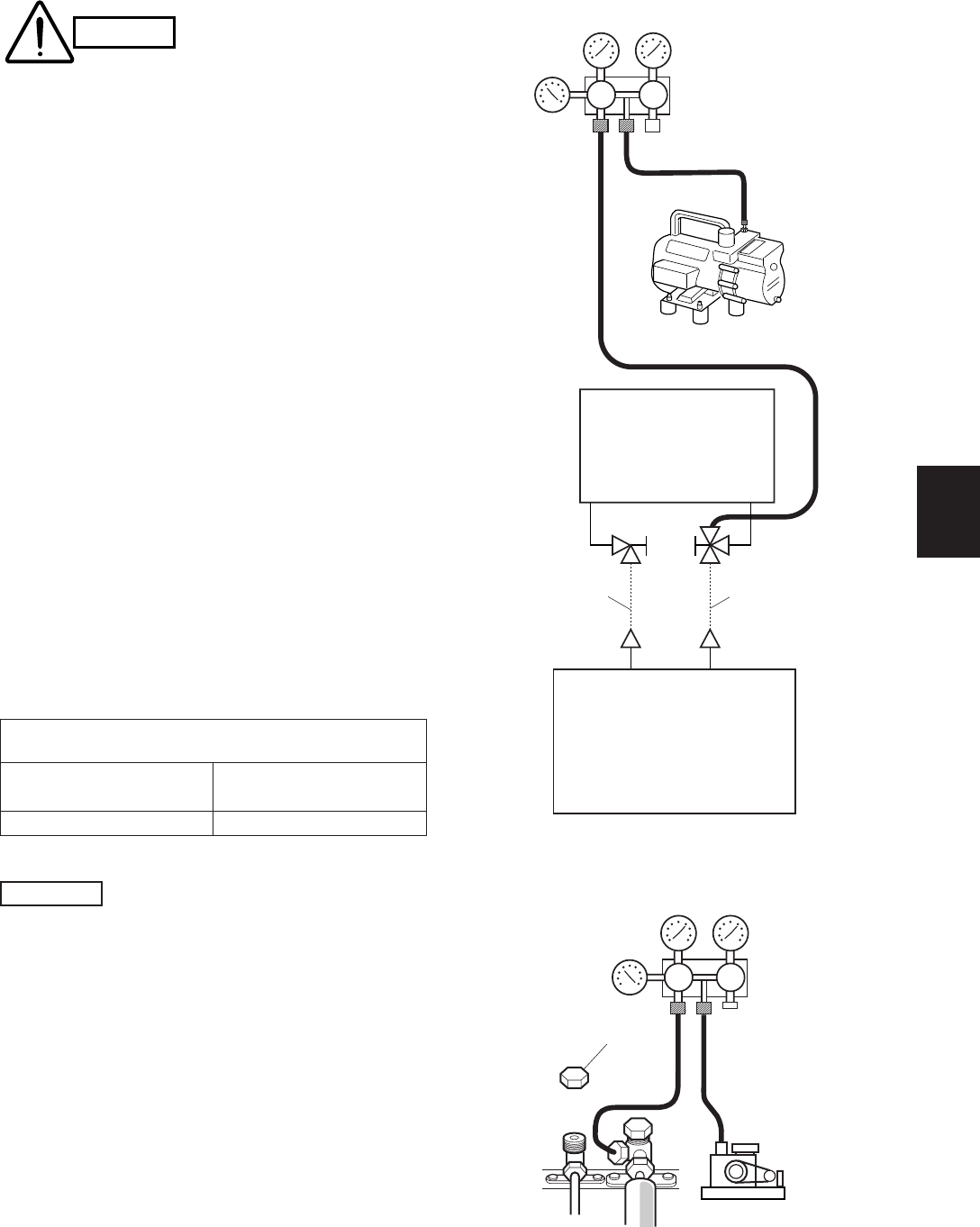

Evacuation

(1) Attach the charge hose end (described in the

preceding steps) to the vacuum pump to evacu-

ate the tubing and indoor unit.

Confirm that the “Lo” knob of the manifold valve

is open. Then, run the vacuum pump. The

operation time for evacuation varies with the

tubing length and capacity of the pump. The

following table shows the required time for

evacuation:

The required time in the above table is calculated on

the assumption that the ideal (or target) vacuum

condition is around 10 mmHg abs.

(2) When the desired vacuum is reached, close the

“Lo” knob of the manifold valve and turn off the

vacuum pump.

If tubing length is

less than 50 ft.

45 minutes or more

If tubing length is

longer than 50 ft.

90 minutes or more

Required time for evacuation

when 30 gal/h vacuum pump is used

NOTE

Vacuum pump

Cap

Narrow tube

Wide tube

Manifold valve

Vacuum

gauge

Lo Hi

0540_C_I

Fig. 11-4

Manifold valve

Pressure

gauge

Lo Hi

Outdoor unit

Service

valve

Wide tubeNarrow

tube

Indoor unit

2091_C_

I

Vacuum pump

*

3-way valve is used for 3642 type.

*

Fig. 11-3