2.2 HYDRAULIC DRIVE UNIT

General guidelines

The hydraulic drive unit should be

mounted clear of spray and the possibility

of immersion in water. It should be

located as near as possible to the

hydraulic steering cylinder. It is important

to bolt the hydraulic drive unit securely to

a substantial member to avoid any

possibility of vibration that could damage

the inter-connecting pipework.

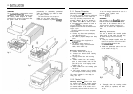

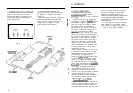

There are three basic types of hydraulic

steering system, and these are illustrated

in Fig. 15. Typical connection points for

the drive unit are shown in each case. In

all cases it is strongly recommended that

the steering gear manufacturer be

consulted.

Minimisation of hydraulic fluid loss

during connection of the drive unit will

help to reduce the time and effort

required later to bleed the system of

trapped air. Absolute cleanliness is

essential since even the smallest particle

of foreign matter could interfere with the

correct function of precision check valves

in the steering system.

Fig. 15

When the installation has been

completed the hydraulic pump may be

operated by switching the control unit to

Auto and operating the +

10”

and

-

10’

course change buttons. Greater motor

movements will be obtained if the rudder

control is set to maximum.

The hydraulic steering system should be

bled according to the manufacturer’s

instructions. From time to time during the

bleeding process the drive unit should be

run in both directions to clear trapped air

from the pump and inter-connecting pipe

work.

If the air is left in the system the

steering will feel spongy particularly when

the wheel is rotated to the hardover

position. Trapped air will severely impair

correct operation of the autopilot and the

steering system and must be removed.

During the installation of the system it

has not been necessary to keep track of

the connection sense to the hydraulic

steering circuit since operating sense of

the autopilot can be corrected if necessary

by reversing the pobrity of the pump drive

motor connections (see section 3.3.1).

%

T.40 Line

:

System

RESERVOIR

r(

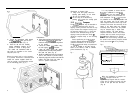

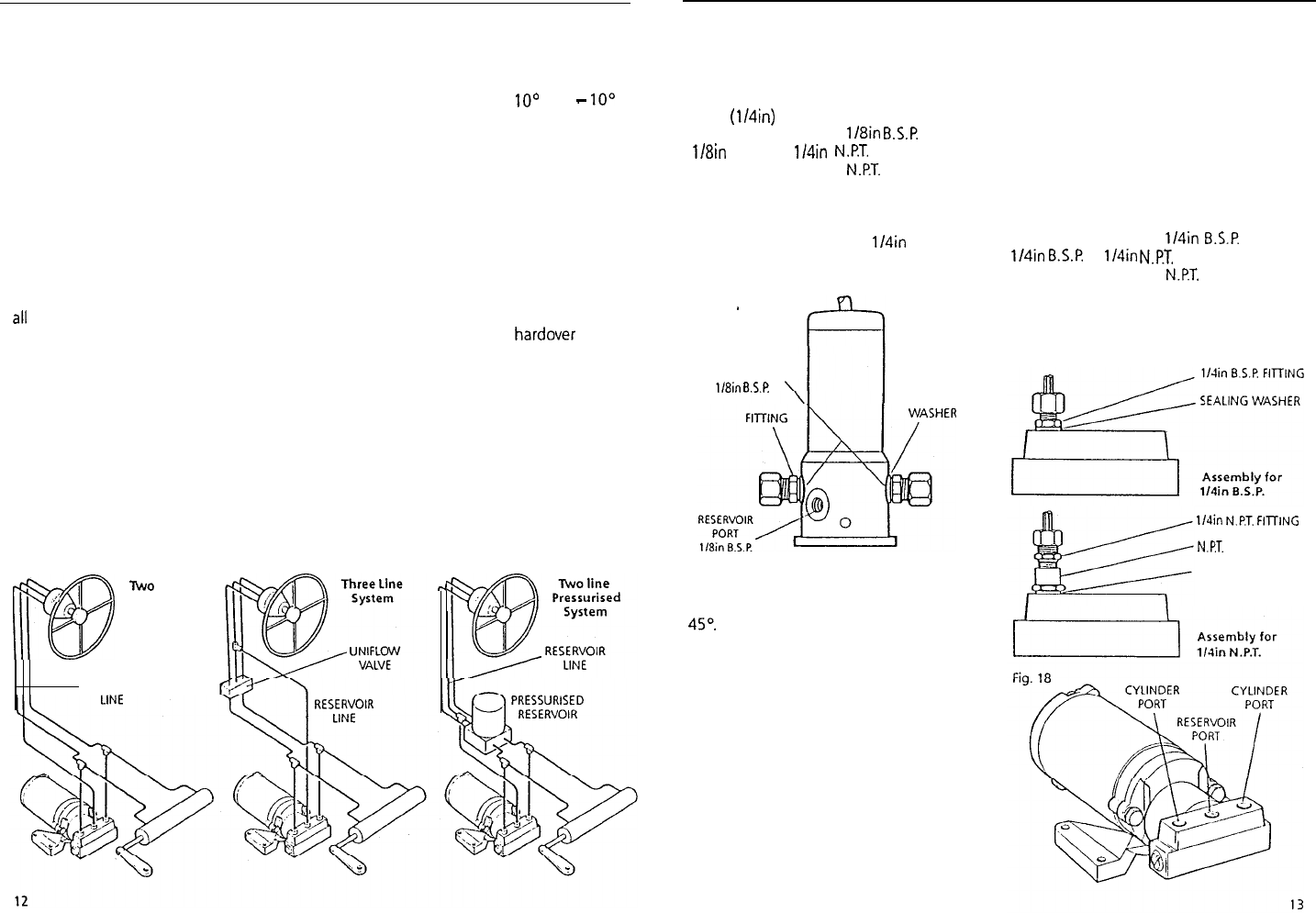

2.2.1 Type 0 Installation

The Type 0 pump must be mounted

vertically with the mounting flange bolted

to a suitable horizontal surface using four

6mm

(114in)

bolts.

All ports are tapped

1/8in

B.S.P.

Three

1/8in B.S.P. to 1/4in

N.PT.

adaptors are

included to convert to

N.PT.

where

required. The sealing washers supplied

should be placed between the fitting and

the pump (Fig. 16).

It is recommended that

1/4in

fittings or

larger are used throughout to minimise

transmission losses.

Fig. 16

’

STEERING

CYLINDER PORTS

l/h

B.S.P.

SEALING

The two cylinder ports are positioned

opposite one another on the pump body.

The reservoir port is marked R and is at

45“.

All connections to the pump should

be made with flexible hose.

Important Note

All connections in the reservoir line

must be sound as any air introduced

to this line will seriously degrade

pump performance.

Bleeding

The type 0 pump is sensitive to trapped

air, and care must be taken during

installation and commissioning to remove

it. Before connecting the hoses to the

pump:

l

Ensure all hoses are filled with oil

l

Prime the pump ports with oil

When operating the hydraulic pump to

bleed the system, turn the helm pump in

opposition. This will help any air expelled

from the hydraulic pump rise to the helm

pump reservoir.

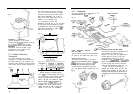

2.2.2 Type 1 Installation

The Type 1 pump should be mounted on a

suitable horizontal surface.

All ports are tapped 1/4in

B.S.P.

Three

114in

B.S.P.

to

114in

N.PT.

adaptors are

included to convert to

N.PT.

where

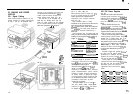

required (Fig. 17). The sealing washers

supplied should be placed between the

fitting and the pump (Fig. 18).

Fig. 17

l/din

N.P.T.

FirriNG

N.PT. ADAPTOR

SEALING WASHER