l

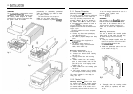

Thread the interconnect cable through

the

17mm

(518in) hole, peel off the

backing from the pads (Fig. 5).

l

Press the unit onto the mounting

surface maintaining pressure for 30

seconds to ensure a strong bond.

The control unit interconnect cable is

now ready for connection to the course

computer (See 2.3).

Where the control unit is to be mounted

to a painted, varnished or untreated wood

surface the carriers supplied should be

used to provide a sound bonding surface

for the

mounting

pads.

(Fig. 6).

Instructions

l Using the template supplied mark off

and drill the 17mm

(518in)

hole and

mark off and pilot drill the fixing holes

for the carriers.

l

Screw the holders

inio

position using

the self tapping screwS provided.

l

Clean the holder surface with alcohol

(oiequivalent) and stick the positive

lock pads into place (Fig. 6).

l Note An additional foam seal must be

used in this method to provide sealing.

l Carefully align the control unit with the

holders and press firmly into place to

secure a positive attachment.

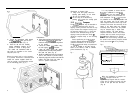

Removing a Control Unit

l

Using a flat lever gently unlock the

securing pads starting at one corner.

l

Do not use excessive force.

0

The unit may be re-attached by

pressing

it’back

onto the security pads.

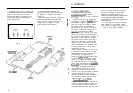

2.1.3 Fluxgate Compass

The

fluxgate

compass may be attached to

a convenient bulkhead using the self

tapping screws provided. Unscrew the top

cap to release the compass housing from

the mounting bracket (Fig. 7). Screw the

bracket to the bulkhead using the self

tapping screws provided and finally

re-

attach’the compass body to the mounting

bracket.

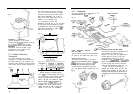

Correct positioning of the fluxgate is

crucial if ultimate performance from the

autopilot installation is to be achieved.

The

fluxgate

should ideally be positioned

as near as possible to the pitch and roll

centre of the vessel in order to minimise

gimbal disturbance (Fig. 8).

Fig. 7

Fig.

6

8

It is very important to ensure that the

fluxgate

is positioned at least 0.8m

(2ft6in)

away from the vessel’s steering

compass in order to avoid deviation of

both compasses. The

fluxgate

must also

be positioned as far away as possible from

large iron masses, such as the engine and

other magnetic devices which may cause

deviation and reduce the sensitivity of the

sensor. If any doubt exists over magnetic

suitability of the chosen site, the position

may be surveyed using a simple hand

bearing compass. The hand bearing

compass should be fixed in the chosen

position and the vessel swung through

360°. Relative differences in reading

between the hand bearing compass and

the vessel’s main steering compass should

ideally not exceed

5O

on any heading.

Fig.

8

.

0.3c to 0.5L

-I

I

.

L

+i

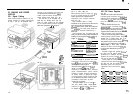

When the installation is complete the

fluxgate

compass should be

approximately aligned with the vessel’s

centre line by rotating the body until the

arrows on the joint line face the bows

(Fig. 9).

9