MX80L Series Product Manual Chapter 3 - How to Use the MX80

Parker Hannifin Corporation

24

Clean Room Preparation

There is no clean room ‘rating’ for motion control products just individual compatibility with class of clean

rooms. The compatibility is also dependant on measurement location. A point directly below a component

may have a different particle count than at a side location. In an effort to clarify the class of clean room

that our products can be used in with out affecting the overall rating of the clean room, Daedal provides a

Clean Room Class Compatibility chart for product intended for use in such environments. Due to the

moving magnet design of the MX80L, minimal particle generation occurs during operation. MX80L tables

with clean room preparation were tested in Daedal’s vertical laminar flow work station which utilizes ULPA

filters to produce an environment having a cleanliness of class 10 prior to testing. Tables were tested in a

variety of orientations with sampling both below the table and at the carriage mounting surface with a

particle counter capable of measuring 0.3 µm diameter and larger particles. Based on results from testing

following the 209E Federal Standard, the following chart shows the expected clean room compatibility of

the MX80L with Class 10 clean room prep. Consult factory for details on test methodology and results.

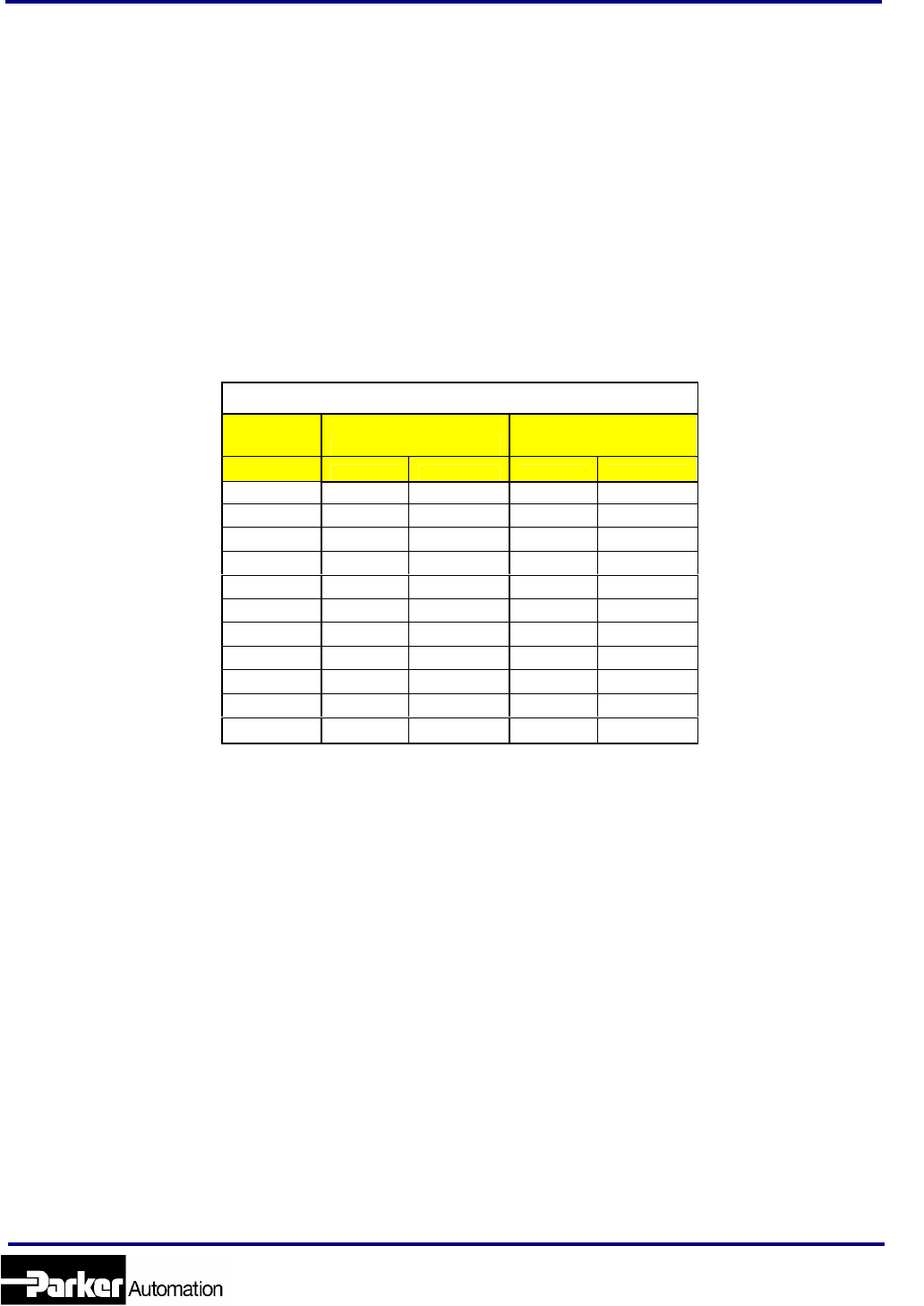

MX80L Clean Room Class Compatibility*

Velocity 25 & 50 mm Travel

100 & 150 mm

Travel

[mm/sec]

4.5" below At stage top 4.5" below At stage top

1 1 1 5 1

5 1 1 5 1

10 1 1 5 1

25 1 1 5 1

50 1 1 10 5

100 1 1 10 5

250 1 5 25 10

500 10 5 50 10

1000 25 10 50 25

1500 n/a 25 100 25

2000 n/a n/a 100 25

* Compatibility is defined as not affecting the clean room class rating with the addition of this product for classes shown.

For example a MX80L with 50mm travel with a velocity of 500mm/sec will not effect a class 10 clean room or higher.

The Class 1 rating in the table refers to class 1 levels of 0.3µ and larger particles detected in Daedal’s Class 10

chamber. For complete class 1 compatibility, the particle count for the 0.1 and 0.2µm particles would also need to be

taken into consideration.

Standard Clean Room Preparation

• Stringent cleaning and handling measures

• Clean room rated lubricant

• Reduce force specification by 25%

Daedal Division

Irwin

,

Penns

y

lvania