6A1 ENGINE (E-W) -

Crankshaft, Cylinder Block, Flywheel and

Drive Plate

11A-15-5

CYLINDER BLOCK

(1) Using a straightedge and feeler gauge, check the block

top surface for warpage. Make sure that the surface is

free from gasket chips an d other foreign matter.

Standard value: 0.05 mm or less

Limit: 0.1 mm

(2) If the distortion is excessive, correct within the allowable

limit or replace.

Grinding limit: 0.2 mm

The total thickness of the stock allowed to be

removed from cylinder block and mating cylinder

head is 0.2 mm at maximum.

Cylinder block height (when new):

6A12 190 mm

6A13 209 mm

(3) Check cylinder walls for scratches and seizure. If defects

are evident, correct (bored to oversize) or replace.

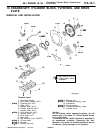

(4) Using cylinder gauge, measure the cylinder bore and

cylindricity. If worn badly, correct cylinder to an oversize

and replace piston and piston rings. Measure at the points

shown in illustration.

Standard value:

Cylinder I.D.:

6A12 78.40 - 78.43 mm

6A13 81.00 - 81.03 mm

Out-of-roundness and taper of cylinder bore:

0.01 mm or less

BORING CYLINDER

(1) Oversize pistons to be used should be determined on

the basis of the largest bore cylinder.

Piston size identification

Size Identification mark

0.50 mm O.S. 0.50

1.00 mm O.S. 1.00

NOTE

Size mark is stamped on piston top.

(2) Measure outside diameter of piston to be used. Measure

it in thrust direction as shown.

(3) Based on measured piston O.D. calculate boring finish

dimension.

Boring finish dimension = Piston O.D. + (Clearance

between piston O.D. and cylinder) - 0.02 mm (honing

margin)

PWEE9622

E

Feb. 1997Mitsubishi Motors Corporation

6AE0103

A

B

CDE

F

G

6AE0104

12 mm

6AE0105