ABS <2WD> -

On-vehicle Service

35B-20

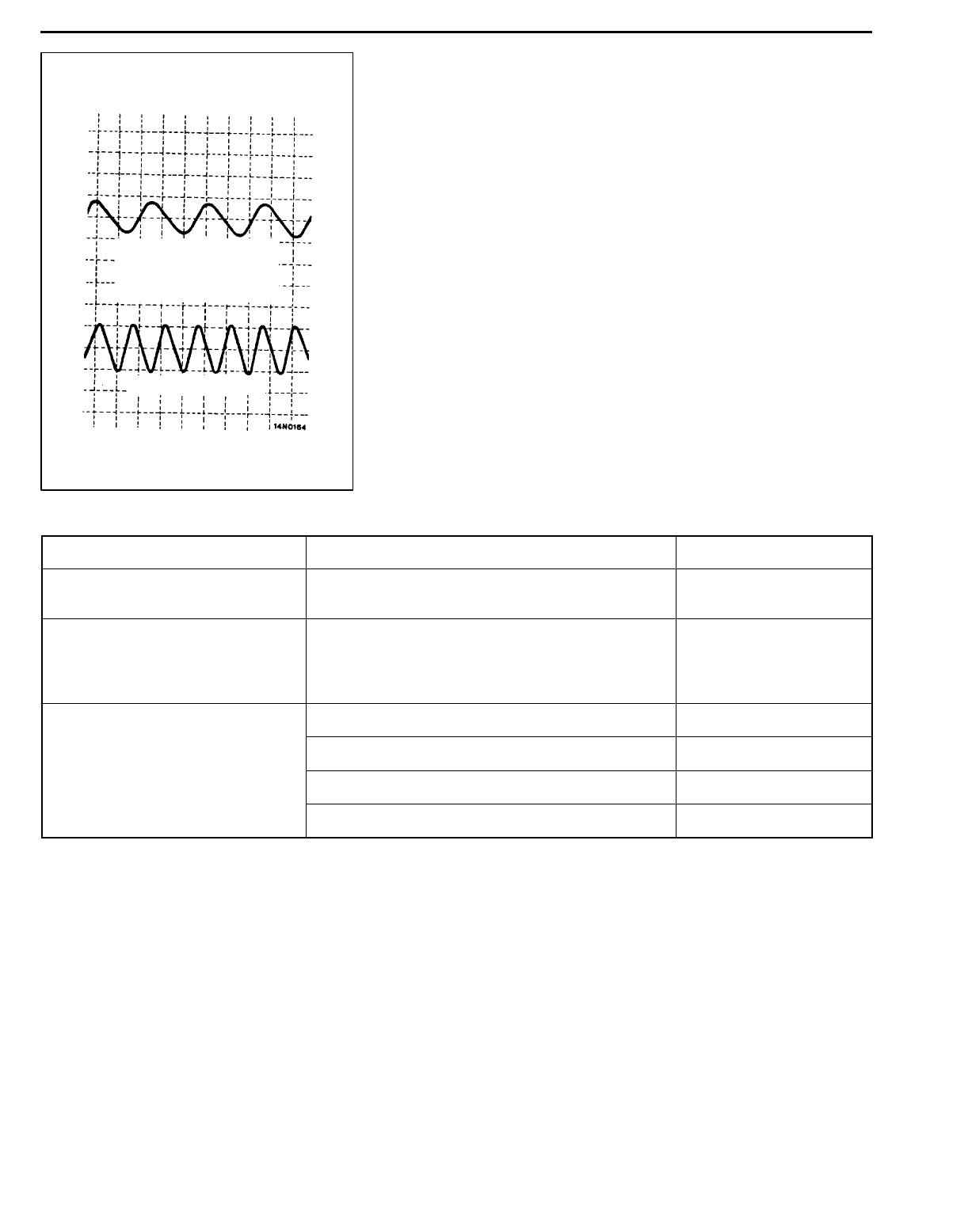

Inspecting Waveforms With An Oscilloscope

Use the following method to observe the output voltage

waveform from each wheel sensor with an oscilloscope.

D Start the engine, and rotate the front wheels by engaging

1st gear (vehicles with manual transmission) or D range

(vehicles with automatic transmission). Turn the rear

wheels manually so that they rotate at a constant speed.

NOTE

1. Check the connection of the sensor harness and

connector before using the oscilloscope.

2. The waveform measurements can also be taken while

the vehicle is actually moving.

3. The output voltage will be small when the wheel speed

is low, and similarly it will be large when the wheel speed

is high.

Points In Waveform Measurement

Symptom Probable causes Remedy

Too small or zero waveform

amplitude

Faulty wheel speed sensor Replace sensor

Waveform amplitude fluctuates

excessively (this is no problem if

the minimum amplitude is 100 mV

or more)

Axle hub eccentric or with large runout Replace hub

Noisy or disturbed waveform Open circuit in sensor Replace sensor

Open circuit in harness Correct harness

Incorrectly mounted wheel speed sensor Mount correctly

Rotor with missing or damaged teeth Replace rotor

Caution

Because the wheel speed sensor cables move together with the front and rear suspension, they

vibrate greatly when driving over poor road surfaces. As a result, the sensor harnesses should

also be shaken when monitoring of output waveforms of the wheel speed sensors in order to

simulate conditions such as driving over poor road surfaces.

When turning by hand

When idling (5-6 km/h),

1st gear (manual trans-

mission) or Drange (auto-

matic transmission)

10.0 ms/DIV 1 V/DIV