BASIC BRAKE SYSTEM -

On-vehicle Service

35A-12

DISC BRAKE ROTOR CHECK

35100290012

Caution

When servicing disc brakes, it is necessary to exercise caution to keep the disc brakes within

the allowable service values in order to maintain normal brake operation.

Before re-finishing or re-processing the brake disc surface, the following conditions should be checked.

Inspection items Remarks

Scratches, rust, saturated lining materials

and wear

D

If the vehicle is not driven for a certain period, the sections of

the discs that are not in contact with lining will become rusty, causing

noise and shuddering.

D

If grooves resulting from excessive disc wear and scratches are

not removed prior to installing a new pad assembly, there will

momentarily be inappropriate contact between the disc and the

lining (pad).

Run-out or drift Excessive run-out or drift of the discs will increase the pedal depression

resistance due to piston knock-back.

Change in thickness (parallelism) If the thickness of the disc changes, this will cause pedal pulsation,

shuddering and surging.

Inset or warping (flatness) Overheating and improper handling while servicing will cause inset or

warping.

THICKNESS CHECK

35100240017

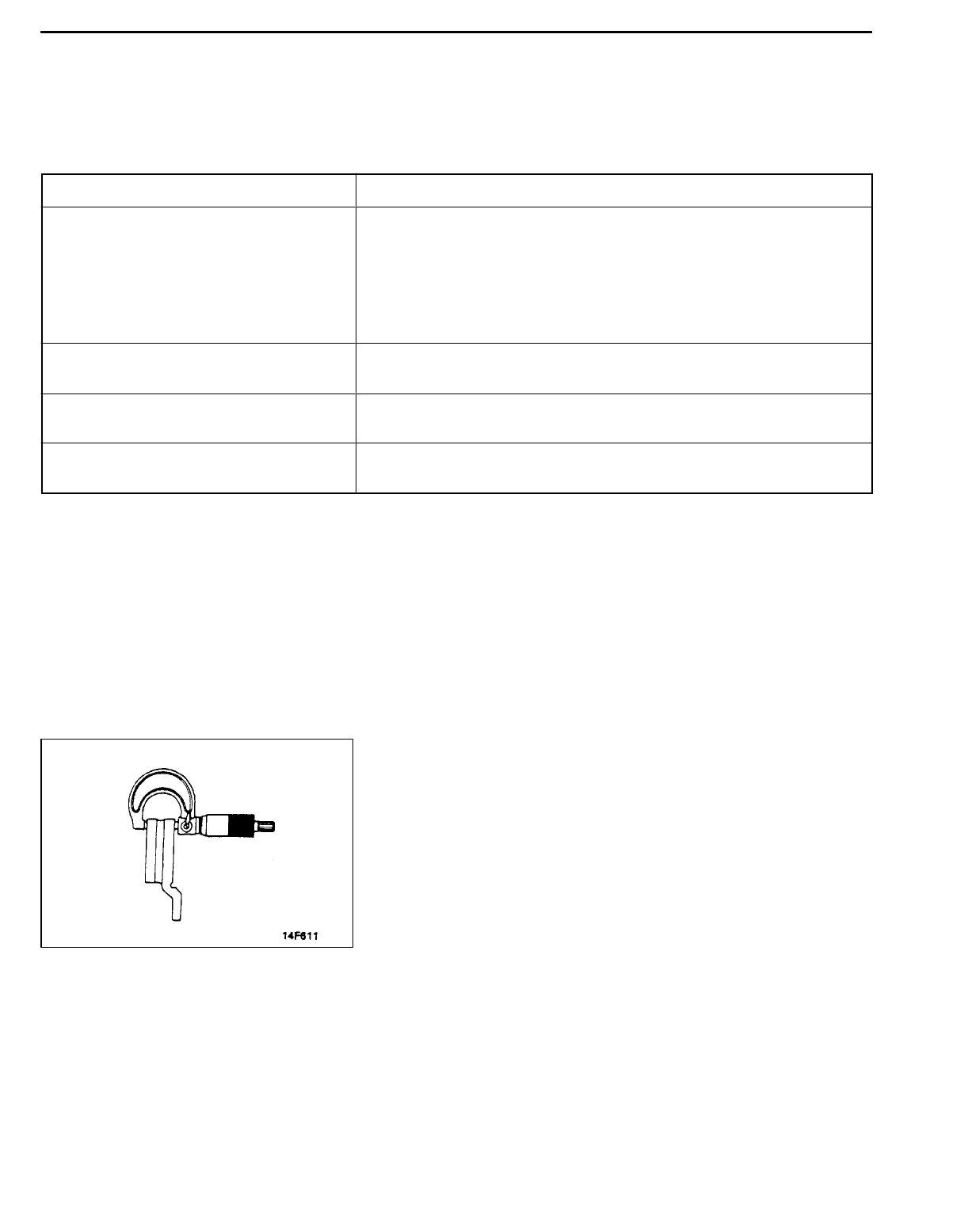

1. Using a micrometer, measure disc thickness at eight

positions, approximately 4 5

_

apart and 10 mm in from

the outer edge of the disc.

Brake disc thickness

Standard value: 24.0 mm <Front>, 10.0 mm <Rear>

Limit: 22.4 mm <Front>, 8.4 mm <Rear>

Thickness variation (at least 8 positions)

The difference between any thickness measurements

should not be more than 0.015 mm.

2. If the disc is beyond the limits for thickness, remove it

and install a new one. If thickness variation exceeds the

specification, replace the brake disc or turn rotor with

on the car type brake lathe (“MAD, DL-8700PF” or

equivalent).