7

MITSUBISHI ELECTRIC

FR-F 740 EC/E1

Flying start

Gentle restart of a rotating motor (e.g. fan

rotated by a draft), also in the opposite di

-

rection.

PTC temperature sensor input

The motor’s internal PTC temperature sen

-

sor can be connected to the inverter di

-

rectly. In combination with the electronic

temperature monitoring system this provi

-

des effective protection for the motor.

Active current limiting

Tried and tested capabilities like the active

current limiting feature have been retai

-

ned. The characteristics of the current limi

-

ter have now been further improved to

prevent unwanted triggering in response

to overcurrents. Transient overcurrents, for

example those generated when a motor

coasting in reverse is restarted or when an

input contactor is closed, will no longer

cause unwanted triggering of the current

limiter.

Magnetic flux vector control

The integrated motor flux vector control

system makes it possible to achieve high

torques, even at low motor speeds.

Optimum excitation control

You can also select the optimum excitation

control mode, which achieves yet more

power savings compared to conventional

inverters designed for pump and fan appli

-

cations.

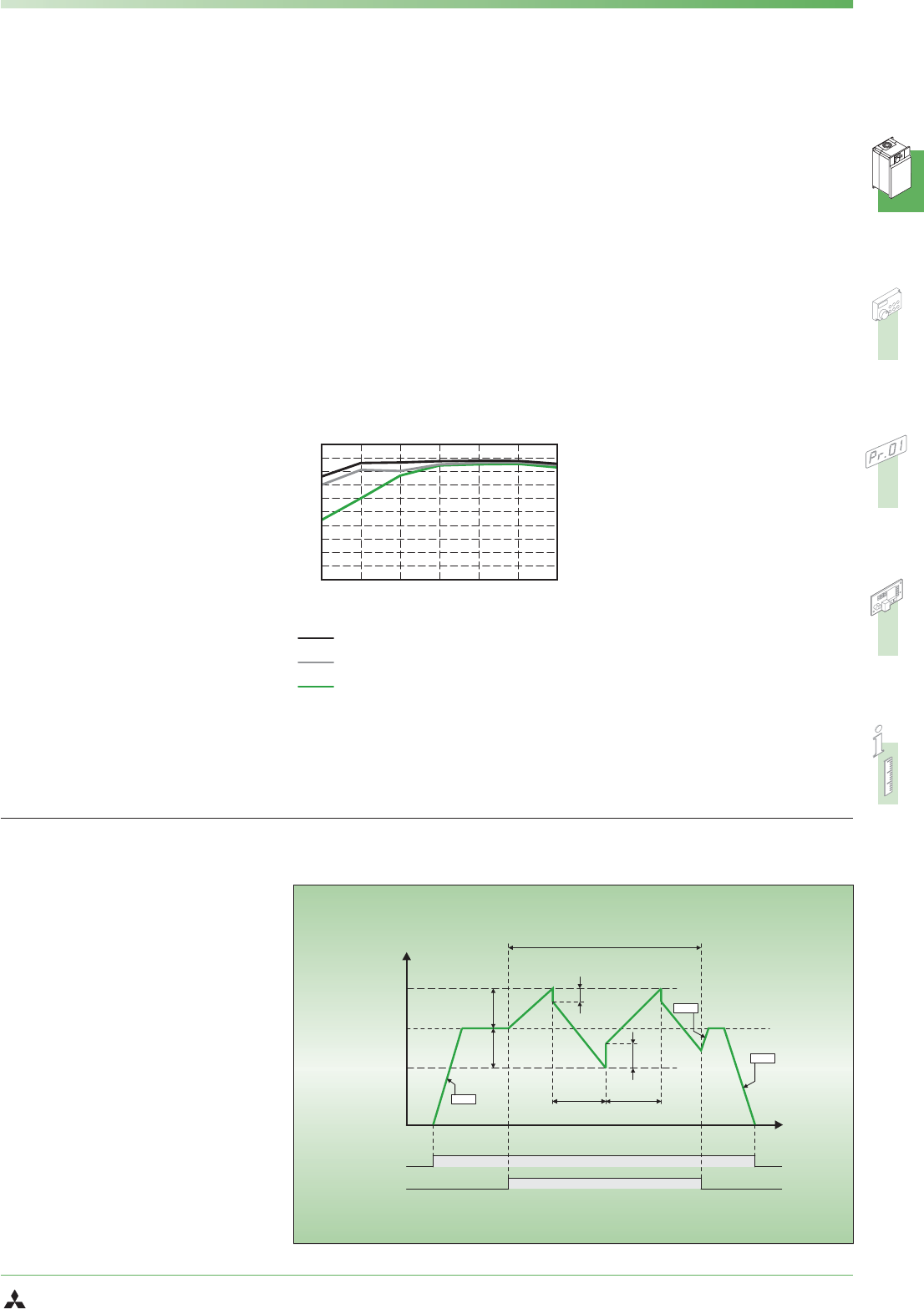

The graph below demonstrates the kind of

improvements that are possible with this

control mode:

Regeneration avoidance function

This function can prevent the inverter from

being shut down by regenerative overvol

-

tages when strong regenerative loads cau

-

se power to be released into the frequency

inverter (for example when braking the

motor or with loads that actively drive the

motor).

The inverter can automatically increase the

output frequency or disable the braking

ramp when a programmed threshold value

is reached. The response sensitivity, dyna

-

mics and working range are all adjustable.

For example, this function can prevent a

shutdownwithanovervoltageerrorwhen

the speed of a fan controlled by the inver

-

ter is increased by the draft from another

fan operating in the same ventilation duct.

The function then temporarily increases

the output frequency above the setpoint

value.

This function can also be used to brake lo

-

ads with the DC bus voltage, without using

braking modules.

Switching to direct mains operation

You can switch the motor to direct mains

operation by programming the contactor

relays accordingly and applying a control

signal to terminals L11 and L21 of the

inverter.

100

90

80

70

60

50

40

30

20

10

0

5% 10% 25% 50% 75% 100% 120%

Torqueload (percentage of rated torque load)

Optimum excitation control mode

Motor efficiency (percent)

Standard energy saving inverter

No excitation control

SYSTEM DESCRIPTION

f2

f3

f1

f1

f0

(Hz)

t1

(Pr.596) t2 (Pr.597)

t(s)

Pr.7

Pr.7

Pr.8

ON

ON

Output frequency

Start/stop

signal

X37 signal

Time (s)

Traverse function

Innovative Features and Functions

Traverse function

The traverse function of the FR-F740 is de

-

signed specifically for use in yarn-winding

applications in the textile industry.

This function performs a cyclical variation

of the output frequency as shown in the

graph on the right. The width of the fluc

-

tuation around the frequency setpoint va

-

lue and the ramp times are configurable

via setup parameters.

This function prevents the formation of the

unwanted “bands” in the wound yarn.