28

MITSUBISHI ELECTRIC

FR-F 740 EC/E1

The frequency inverter FR-F 740 provides a

large number of protective functions that

protect the drive and the inverter against

damage in case of any malfunction.

If an error occurs, the output of the inverter

is suspended and the control panel

returns an error message.

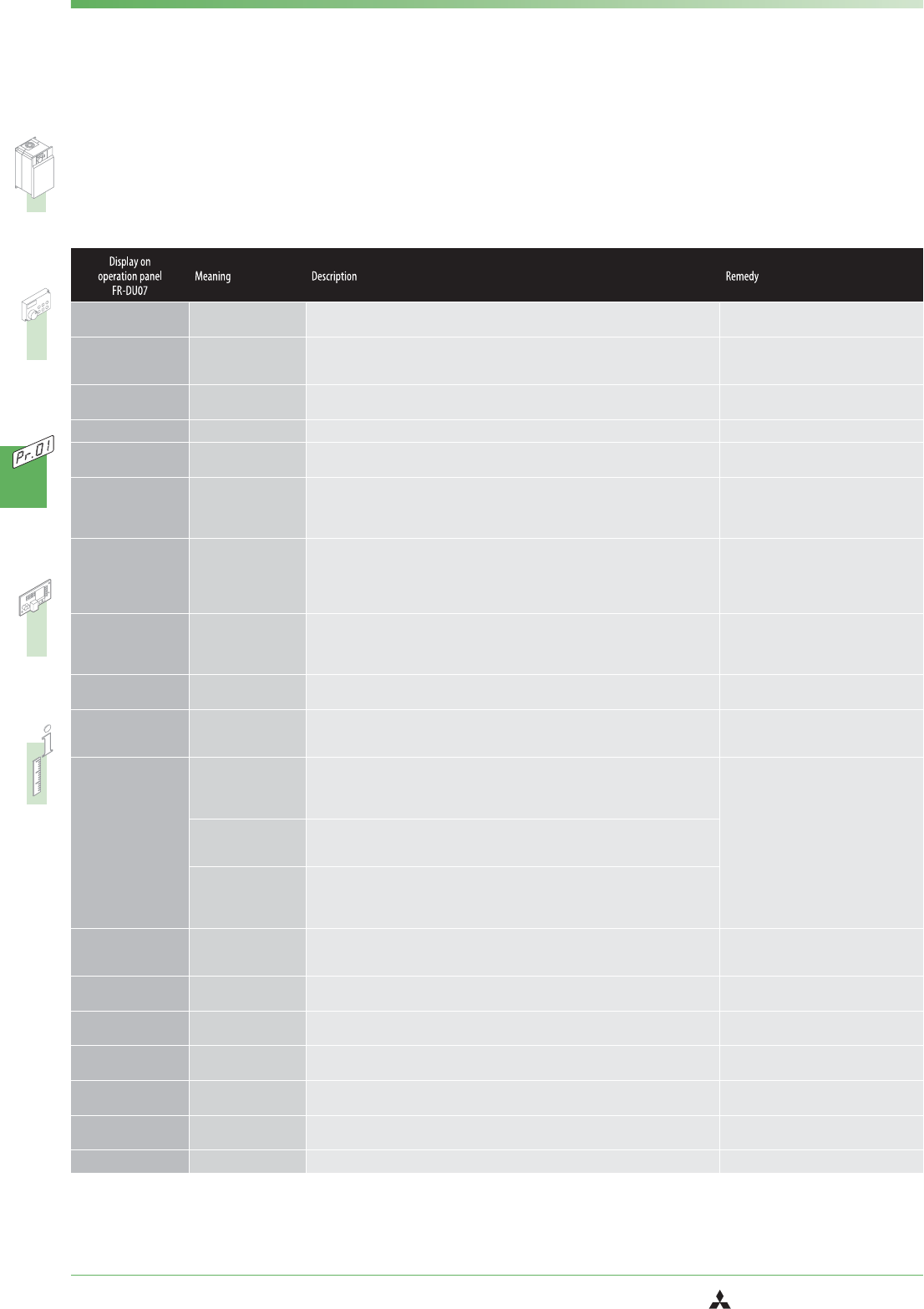

Protective Functions Overview

HOLD

ቢ

Operation panel lock Operation lock mode ist set.

Press and hold the MODE key for 2 s to enable

the operation panel.

Er1

ቢ

Write disable error

This error occurs when a write operation is attempted with Pr.77 = 1,the frequency jump ranges

overlap,the ranges for the flexible 5-point V/f characteristic overlap or no communication is possi

-

ble between the control panel and the frequency inverter.

Check the setting of Pr.77,Pr.31 to 36 Pr.100 to

109 and the connection of the operation panel

and inverter.

Er2

ቢ

Write error

This error occurs when a write operation is attempted with the inverter in operation when the value

of Pr.77 <> 2 and an STF or STR start signal is active.

Check the setting of Pr.77.The frequency

inverter must be in stop mode.

Er3

ቢ

Calibration error Analog input bias and gain calibration values are too close. Check the parameter C3,C4,C6 and C7

Er4

ቢ

Mode designation error This error occurs when you try to set a parameter in NET mode when PR.77 <> 2.

Check the setting of Pr.77. Set the operating

mode to operation via control panel.

rE1

ቢ

Parameter read error An error occurred in the E²PROM on the operation panel side during parameter copy reading.

Repeat the copy operation.Check the control

panel connections.Please contact your nearest

MITSUBISHI ELECTRIC representative if the error

occurs repeatedly.

rE2

ቢ

Parameter write error An error occurred in the E²PROM on the operation panel side during parameter copy writing.

Repeat the copy operation with the inverter

stopped.Check the control panel connections.

Please contact your nearest MITSUBISHI ELEC-

TRIC representative if the error occurs repeat-

edly.

rE3

ቢ

Parameter verification

error

Data on the operation panel side and inverter side are different.An error occurred in the E²PROM on

the operation panel side during parameter verification.

Press the SET key to continue verification.Check

the control panel connections.Please contact

your nearest MITSUBISHI ELECTRIC representa-

tive if the error occurs repeatedly.

rE4

ቢ

Model error A different model was used for parameter write and verification during parameter copy.

Use the same model for parameter copy and

verification.

Err.

Error

The RESET signal is active or there is an error in the communication between the frequency inverter

and the control panel.

Deactivated the RESET signal.Check the con

-

nections between the control panel and the

frequency inverter.

OL

Overcurrent during

acceleration

If a current of more than 110%

ባ

of the rated inverter current flows in the motor,this function

stops the increase in frequency until the overload current reduces to prevent the inverter from re

-

sulting in overcurrent shut-off.When the overload current has reduced below 110%,this function

increases the frequency again.

Increase the stall prevention operation level

with Pr.22 "stall prevention operation level"

or disable stall prevention with Pr.156 "stall

prevention operation selection".

Overcurrent during con

-

stant speed operation

If a current of more than 110%

ባ

of the rated inverter current flows in the motor,this function low

-

ers the frequency until the overload current reduces to prevent overcurrent shut-off.When the over

-

load current has reduced below 110%,this function increases the frequency up to the set value.

Overcurrent during

deceleration

If a current of more than 110%

ባ

of the rated inverter current flows in the motor,this function

stops the decrease in frequency until the overload current reduces to prevent theinverter from re

-

sulting in overcurrent shut-off.When the overload current has reduced below 110%,this function

decreases the frequency again.

oL

Overvoltage during

deceleration

If the regenerative energy of the motor increases too much to exceed the brake capability,this func

-

tion stops the decrease in frequency to prevent overvoltage shut-off.As soon as the regenerative

energy has reduced,deceleration resumes.

Increase the deceleration time with Pr.8 "decel

-

eration time".

rb

Regenerative brake

prealarm

Too much energy is being fed into the brake resistor (model 01800 and above).

Increase the deceleration time.Check the Pr.30

and 70 values.

PS

Inverter was stopped via

control panel

STOP key on the control panel was pressed during external operating mode. Check the parameter 77.

TH

Electronic thermal relay

function prealarm

The prealarm of the electronic motor protection switch has activated. The load or number of work cycles is too high.

MT

ቢ

Maintenance signal

output

The cumulated operating time has reached the preset value.

The value in Pr.503 is larger than the setting of

Pr.504.

CP

Parameter copy

Attempt to perform a copy operation from a frequency inverter model 01160 or lower to a model

01800 or higher.

Reset parameters 9,30,51,52,54,56 57,61,70,

72,80,90,158,190-196 and 893.

FN

Fan fault The cooling fan is not operating as set in Pr.244. Replace the cooling fan.

PROTECTIVE FUNCTIONS